2.

Oil the stem of each valve

lightly

and insert each

in

its own guide.

3. Check each valve for a

tight

seat

with

an air

pressure

type

tester.

If a

tester

is not available,

make pencil marks at intervals on the valve face

and observe if the marks rub off

uniformly

when

the valve is rotated part of a

turn

in the

seat.

If

the

seat

is not

tight,

regrind the valves.

4.

Using a valve spring compressor, compress each

valve

spring and insert the valve spring retainer,

and retainer locks.

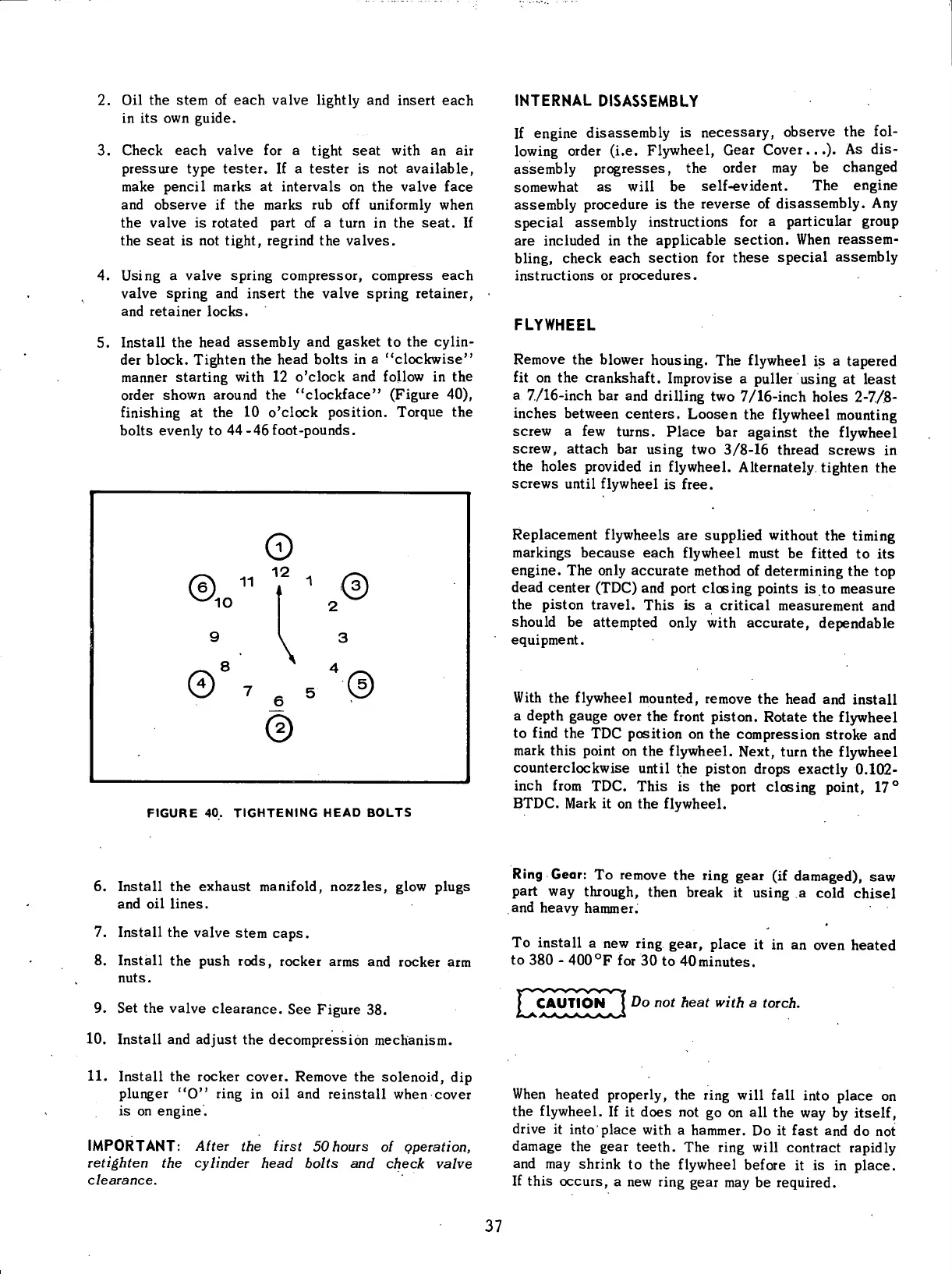

5.

Install

the head assembly and gasket to the

cylin-

der block. Tighten the head bolts in a "clockwise"

manner starting

with

12 o'clock and

follow

in the

order shown around the "clockface" (Figure 40),

finishing

at the 10 o'clock position. Torque the

bolts

evenly to 44-46foot-pounds.

FIGURE

40.

TIGHTENING

HEAD

BOLTS

INTERNAL

DISASSEMBLY

If

engine disassembly is

necessary,

observe the

fol-

lowing

order (i.e.

Flywheel,

Gear Cover...). As dis-

assembly

progresses,

the order may be changed

somewhat as

will

be self-evident. The engine

assembly procedure is the reverse of disassembly. Any

special assembly instructions for a particular group

are included in the applicable section. When

reassem-

bling,

check each section for

these

special assembly

instructions

or procedures.

FLYWHEEL

Remove the blower housing. The

flywheel

is a tapered

fit

on the crankshaft. Improvise a puller using at least

a 7./16-inch bar and

drilling

two 7/16-inch holes 2-7/8-

inches between centers. Loosen the

flywheel

mounting

screw a few turns. Place bar against the

flywheel

screw, attach bar using two 3/8-16 thread screws in

the holes provided in

flywheel.

Alternately tighten the

screws

until

flywheel

is free.

Replacement flywheels are supplied

without

the

timing

markings

because

each

flywheel

must be

fitted

to its

engine. The

only

accurate method of determining the top

dead center

(TDC)

and port closing points is.to

measure

the piston

travel.

This is a

critical

measurement and

should

be attempted

only

with

accurate, dependable

equipment.

With

the

flywheel

mounted, remove the head and

install

a depth

gauge

over the

front

piston. Rotate the

flywheel

to

find

the TDC position on the compression stroke and

mark

this point on the

flywheel.

Next,

turn

the

flywheel

counterclockwise

until

the piston drops exactly 0.102-

inch

from

TDC. This is the port closing point, 17°

BTDC.

Mark

it on the

flywheel.

6.

Install

the exhaust

manifold,

nozzles,

glow

plugs

and oil lines.

7.

Install

the valve stem

caps.

8.

Install

the push rods, rocker arms and rocker arm

nuts.

9. Set the valve clearance. See Figure 38.

10.

Install

and adjust the decompression mechanism.

11.

Install

the rocker cover. Remove the solenoid, dip

plunger

"O"

ring

in oil and reinstall when cover

is

on engine.

IMPORTANT: Alter

the

first SOhours

ol

operation,

retighten

the

cylinder head bolts

and

check valve

clearance.

Ring

Gear: To remove the

ring

gear

(if damaged), saw

part way through, then break it using a

cold

chisel

and heavy hammer.

To

install

a new

ring

gear,

place it in an oven heated

to

380 - 400

0

F for 30 to 40minutes.

j^CAUTION

Do

not

heat with

a

torch.

When

heated properly, the

ring

will

fall

into

place on

the

flywheel.

If it

does

not go on all the way by

itself,

drive

it

into

place

with

a hammer. Do it fast and do not

damage

the

gear

teeth. The

ring

will

contract

rapidly

and may shrink to the

flywheel

before it is in place.

If

this occurs, a new

ring

gear

may be required.

37

Loading...

Loading...