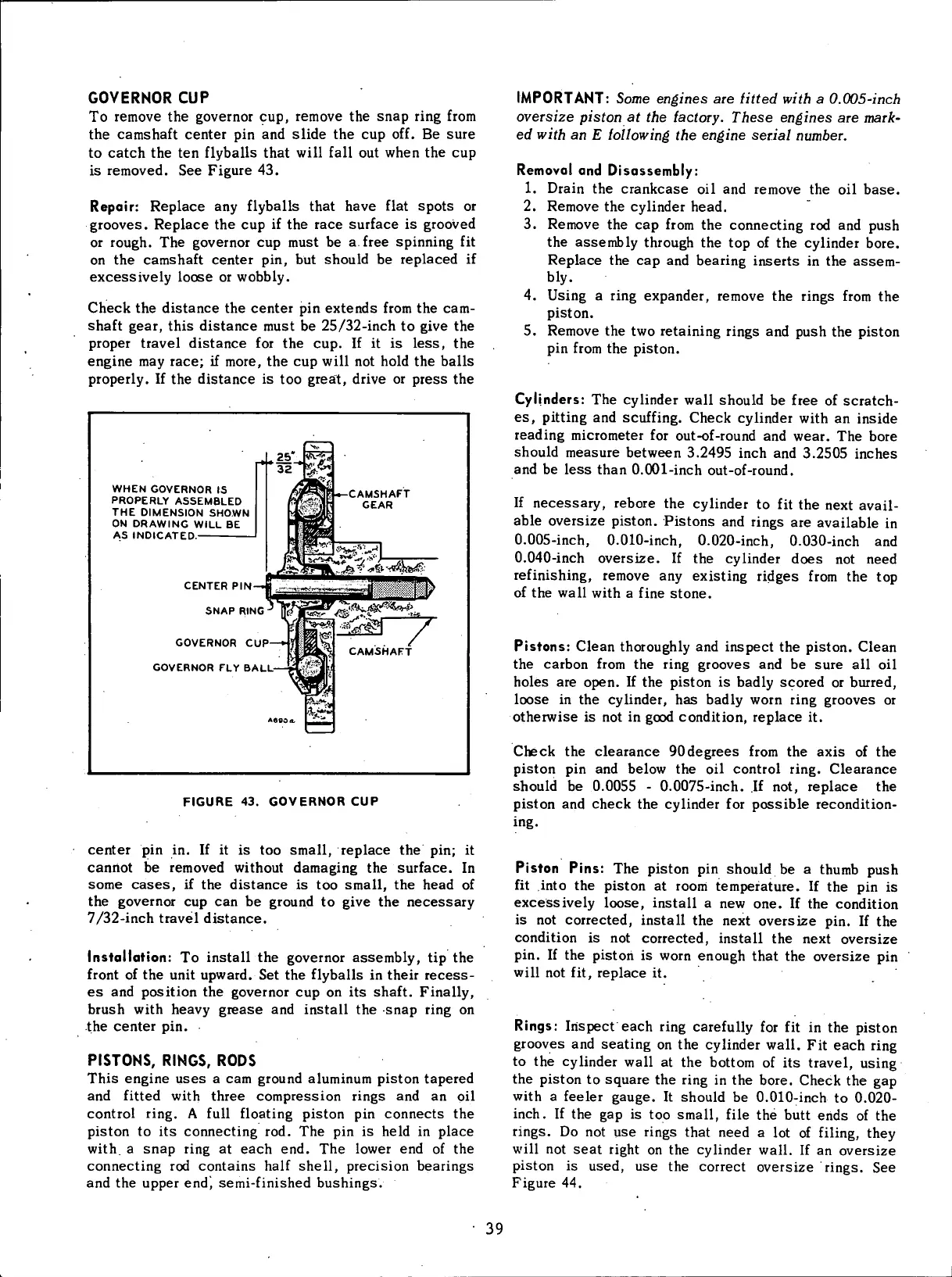

GOVERNOR

CUP

To

remove the governor cup, remove the

snap

ring

from

the camshaft center pin and slide the cup off. Be

sure

to

catch the ten

flyballs

that

will

fall

out when the cup

is

removed. See Figure 43.

Repair: Replace any

flyballs

that have

flat

spots

or

grooves. Replace the cup if the

race

surface is grooved

or

rough. The governor cup must be a.

free

spinning fit

on

the camshaft center pin, but should be replaced if

excessively loose or

wobbly.

Check the distance the center pin extends

from

the cam-

shaft

gear,

this distance must be 25/32-inch to give the

proper travel distance for the cup. If it is

less,

the

engine may race; if more, the cup

will

not

hold

the balls

properly.

If the distance is too great, drive or

press

the

IMPORTANT: Some engines

are

fitted with

a

0.005-inch

oversize piston

at the

factory. These engines

are

mark-

ed

with

an E

following

the

engine serial number.

WHEN

GOVERNOR

IS

PROPERLY

ASSEMBLED

THE

DIMENSION

SHOWN

ON

DRAWING

WILL

BE

AS

INDICATED.

CENTER

PIN

SNAP

RING

GOVERNOR

CUP—•

GOVERNOR

FLY

BALL

FIGURE

43. GOVERNOR CUP

center pin in. If it is too small, replace the pin; it

cannot be removed

without

damaging the surface. In

some

cases,

if the distance is too small, the head of

the governor cup can be ground to give the

necessary

7/32-inch

travel distance.

Installation:

To

install

the governor assembly, tip the

front

of the

unit

upward. Set the

flyballs

in their

recess-

es and position the governor cup on its shaft.

Finally,

brush

with

heavy

grease

and

install

the

snap

ring

on

the center pin.

PISTONS,

RINGS,

RODS

This

engine

uses

a cam ground aluminum piston tapered

and

fitted

with

three compression rings and an oil

control

ring.

A

full

floating

piston pin connects the

piston

to its connecting rod. The pin is held in place

with,

a

snap

ring

at each end. The lower end of the

connecting

rod contains

half

shell, precision bearings

and the upper end', semi-finished bushings.

Removal and Disassembly:

1.

Drain

the crankcase oil and remove the oil

base.

Remove the cylinder head.

Remove the cap

from

the connecting rod and push

the assembly through the top of the cylinder bore.

Replace the cap and bearing inserts in the

assem-

bly.

Using

a

ring

expander, remove the rings

from

the

piston.

Remove the two retaining rings and push the piston

pin

from

the piston.

2.

3.

4.

5.

Cylinders:

The cylinder

wall

should be free of scratch-

es,

pitting

and

scuffing.

Check cylinder

with

an inside

reading micrometer for out-of-round and wear. The bore

should

measure

between 3.2495

inch

and 3.2505 inches

and be

less

than 0.001-inch out-of-round.

If

necessary,

rebore the cylinder to

fit

the next

avail-

able oversize piston. Pistons and rings are available in

0.005-inch,

0.010-inch, 0.020-inch, 0.030-inch and

0.040-inch

oversize. If the cylinder

does

not need

refinishing,

remove any existing ridges

from

the top

of

the

wall

with

a

fine

stone.

Pistons: Clean thoroughly and inspect the piston. Clean

the carbon

from

the

ring

grooves and be

sure

all oil

holes are open. If the piston is badly scored or burred,

loose in the cylinder, has badly

worn

ring

grooves or

otherwise is not in good

condition,

replace it.

Check the clearance

90degrees

from

the axis of the

piston

pin and below the oil

control

ring.

Clearance

should

be 0.0055 - 0.0075-inch. If not, replace the

piston

and check the cylinder for possible recondition-

ing.

Piston

Pins: The piston pin should be a thumb push

fit

into

the piston at room temperature. If the pin is

excessively loose,

install

a new one. If the

condition

is

not corrected,

install

the next oversize pin. If the

condition

is not corrected,

install

the next oversize

pin.

If the piston is

worn

enough that the oversize pin

will

not

fit,

replace it.

Rings:

Inspect each

ring

carefully for fit in the piston

grooves and seating on the cylinder

wall.

Fit each

ring

to

the cylinder

wall

at the bottom of its

travel,

using

the piston to

square

the

ring

in the bore. Check the gap

with

a feeler gauge. It should be 0.010-inch to 0.020-

inch.

If the gap is too small,

file

the butt

ends

of the

rings.

Do not use rings that need a lot of

filing,

they

will

not

seat

right

on the cylinder

wall.

If an oversize

piston

is used, use the correct oversize rings. See

Figure

44.

'

39

Loading...

Loading...