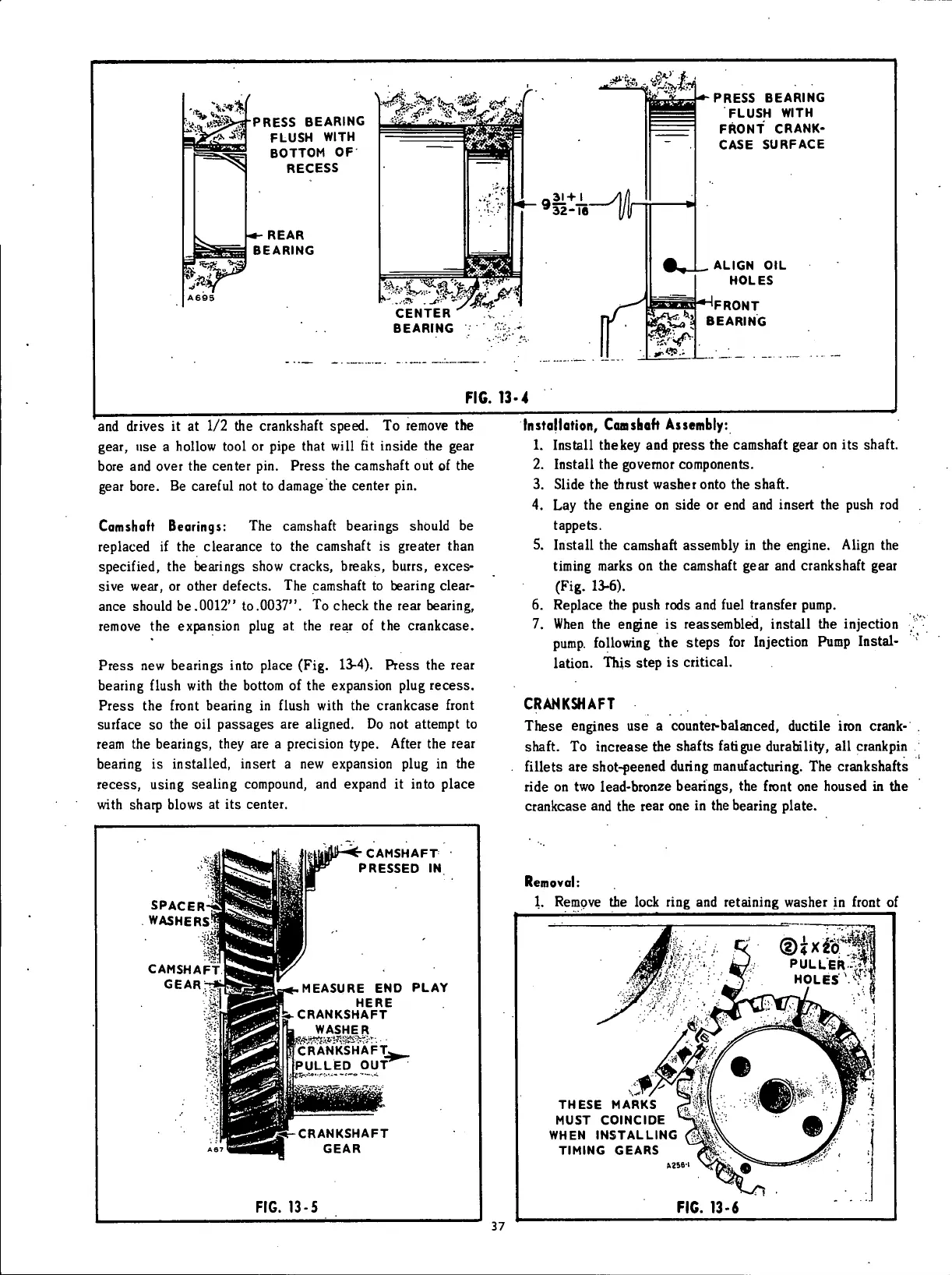

PRESS BEARING

FLUSH WITH

BOTTOM

OF

RECESS

«- REAR

BEARING

^32-16

PRESS BEARING

FLUSH WITH

FRONT CRANK-

CASE SURFACE

ALIGN

OIL

HOLES

FRONT

BEARING

FIG.

13-4

and

drives it at 1/2 the crankshaft

speed.

To remove the

gear,

use a

hollow

tool

or pipe that

will

fit inside the

gear

bore and over the center

pin.

Press

the camshaft out of the

gear

bore. Be

careful

not to damage the center pin.

Camshaft Bearings: The camshaft bearings should be

replaced if the clearance to the camshaft is greater than

specified,

the bearings show cracks, breaks, burrs, exces-

sive

wear, or other defects. The camshaft to bearing clear-

ance

should be.0012" to.0037". To check the rear bearing,

remove the expansion

plug

at the rear of the crankcase.

Press

new bearings

into

place

(Fig.

13-4).

Press

the rear

bearing

flush

with

the bottom of the expansion

plug

recess.

Press

the

front

bearing in

flush

with

the crankcase

front

surface so the oil

passages

are aligned. Do not attempt to

ream the bearings, they are a precision type.

After

the rear

bearing

is installed, insert a new expansion

plug

in the

recess,

using sealing compound, and expand it

into

place

with

sharp blows at its center.

SPACER-i

WASHERS

|M

CAMSHAFT

GEAR

rrf

m

CAMSHAFT

PRESSED

IN

r

i MEASURE

END

PLAY

HERE

CRANKSHAFT

WASHER

...

^itflSPSS-T'.

•

•

CRANKSHAFT^

PULLED

OUT

-CRANKSHAFT

GEAR

FIG.

13-5

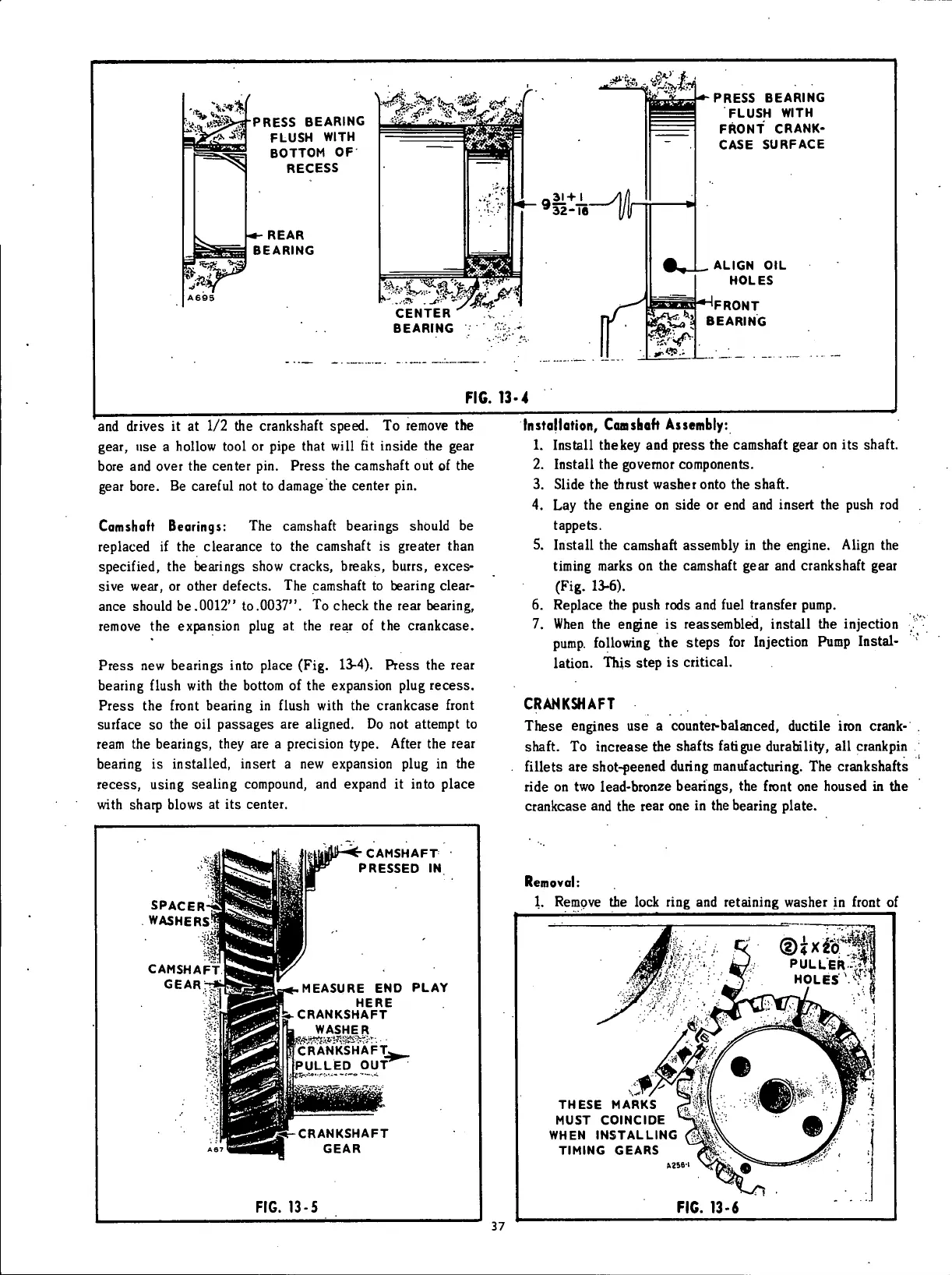

Installation,

Cam

shaft Assembly:

1.

Install

thekey and

press

the camshaft

gear

on

its shaft.

2.

Install

the governor components.

3. Slide the thrust washer

onto

the shaft.

4.

Lay the engine on side or end and insert the push rod

tappets.

5.

Install

the camshaft assembly in the engine.

Align

the

timing

marks on the camshaft

gear

and crankshaft

gear

(Fig.

13-6).

6. Replace the push rods and

fuel

transfer pump.

7.

When the engine is reassembled,

install

the

injection

: •

pump,

following

the

steps

for

Injection

Pump

Instal-

'

lation.

This

step

is

critical.

CRANKSHAFT

These engines use a counterbalanced, ductile

iron

crank- .

shaft. To increase the shafts

fatigue

durability,

all

crankpin

fillets

are shot-peened

during

manufacturing.

The crankshafts

ride

on two lead-bronze bearings, the

front

one housed in the

crankcase and the rear one in

the

bearing

plate.

Removal:

1.

Remove the

lock

ring

and retaining washer in

front

of

THESE MARKS

MUST COINCIDE

WHEN INSTALLING

TIMING GEARS

I12S6-I

FIG.

13-6

37

Loading...

Loading...