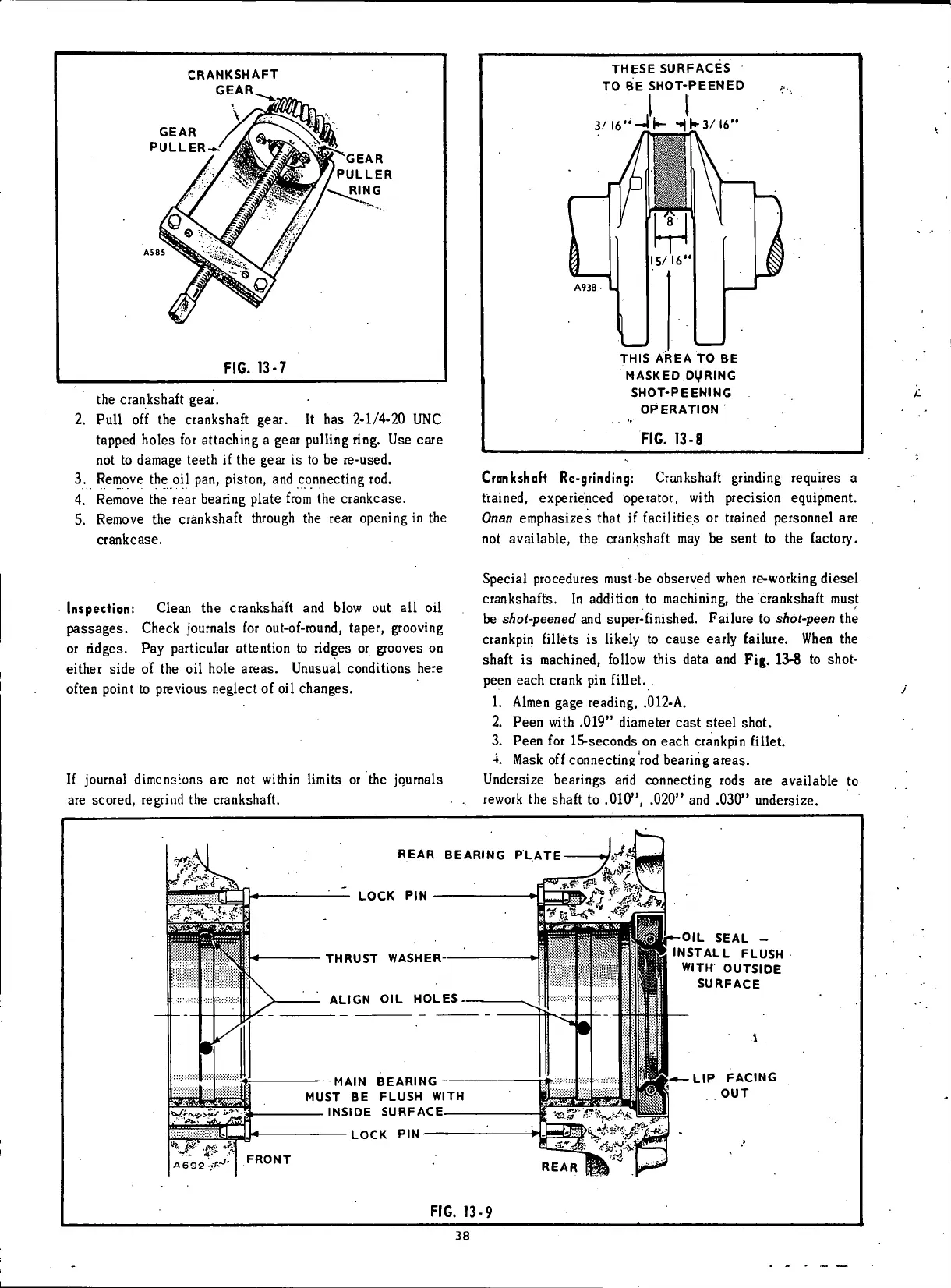

CRANKSHAFT

GEAR^

GEAR

PULLER

^^GEAR

jr/PULLER

AIRING

s#

Jf

^We^V

/ ./

FIG.

13-7

the crankshaft

gear.

2. Pull

off the crankshaft

gear.

It has 2-1/4-20 UNC

tapped holes for attaching a

gear

pulling ring.

Use

care

not

to

damage

teeth if the

gear

is to be re-used.

3. Remove the oil pan, piston, and connecting rod.

4.

Remove the

rear

bearing plate

from

the

crankcase.

5. Remove the crankshaft through the

rear

opening

in

the

crankcase.

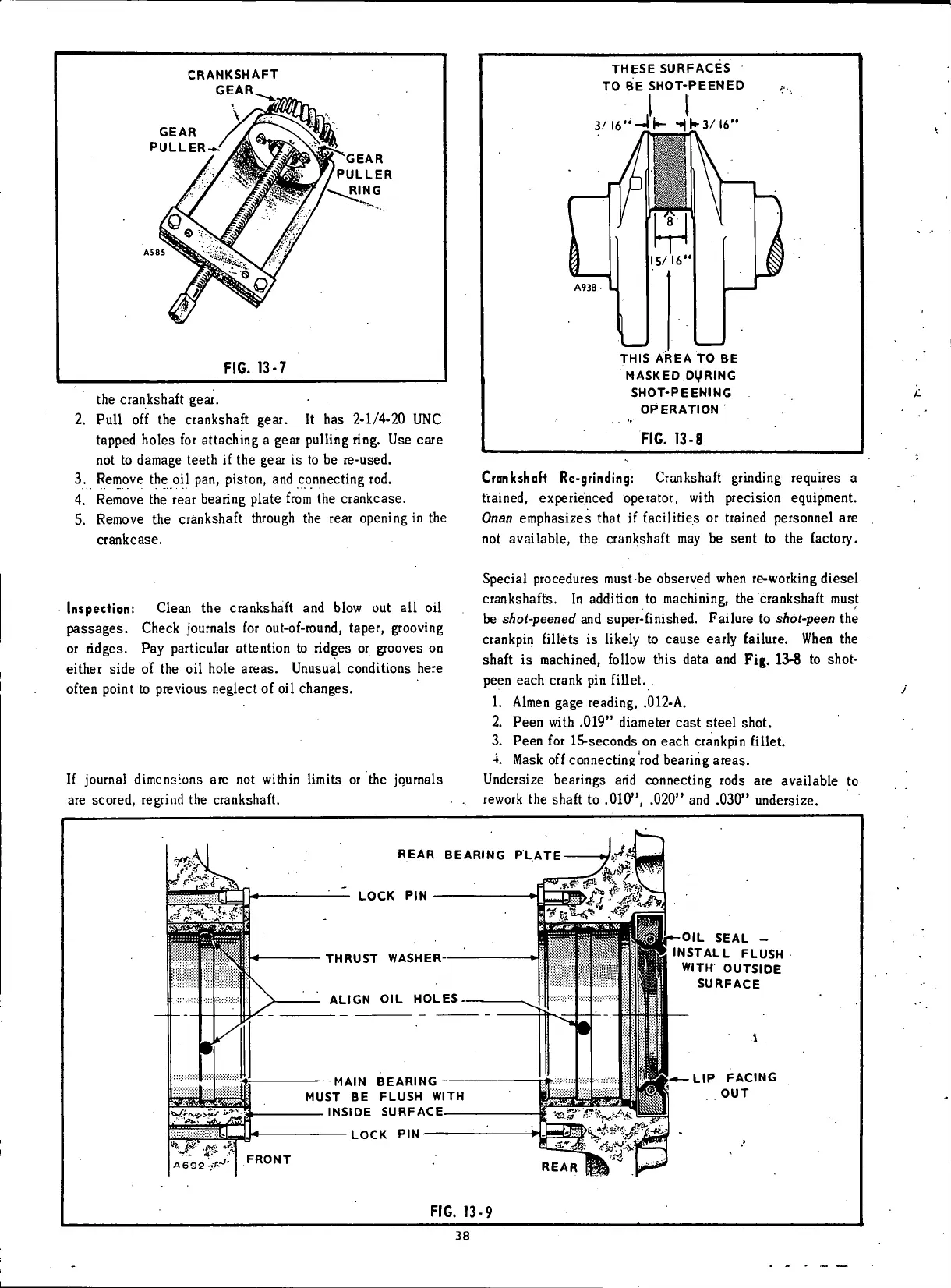

THESE SURFACES

TO

BE

SHOT-PEENED

I

1

3/l6"-Jk

Hka/U"

THIS AREA

TO BE

MASKED DURING

SHOT-PEENING

OPERATION

FIG.

13-8

Crankshaft Re-grinding: Crankshaft grinding requires a

trained,

experienced operator,

with

precision equipment.

Onan

emphasizes

that if

facilities

or trained personnel are

not

available, the crankshaft may be

sent

to the factory.

Inspection:

Clean the crankshaft and

blow

out all oil

passages.

Check journals for

out-of-round,

taper,

grooving

or

ridges. Pay particular attention to ridges or grooves on

either side of the oil hole

areas.

Unusual conditions

here

often

point to previous neglect of

oil

changes.

If

journal dimensions are not

within limits

or the journals

are scored, regrind the crankshaft.

Special procedures must be observed when

re-working

diesel

crankshafts. In addition to machining, the crankshaft must

be

shot-peened

and super-finished. Failure to shot-peen the

crankpin

fillets

is

likely

to

cause

early

failure.

When the

shaft is machined,

follow

this

data

and Fig. 13-8 to shot-

peen

each

crank pin

fillet.

1.

Almen

gage

reading, .012-A.

2.

Peen

with

.019" diameter

cast

steel shot.

3.

Peen

for

15-seconds

on

each

crankpin

fillet.

4.

Mask

off

connecting rod bearing

areas.

Undersize bearings

arid

connecting rods are available to

rework

the shaft to .010", .020" and .030" undersize.

REAR BEARING PLATE

LOCK

PIN

THRUST WASHER

ALIGN

OIL

HOLES

MAIN BEARING

MUST

BE

FLUSH WITH

INSIDE SURFACE

LOCK

PIN

FRONT

OIL SEAL

-

INSTALL FLUSH

WITH OUTSIDE

SURFACE

LIP FACING

OUT

REAR

FIG.

13-9

38

Loading...

Loading...