FUEL

TRANSFER

PUMP

The transfer pump is located on the left side of the

engine. If fuel does not reach the secondary filter,

make the following checks before removing the

pump.

1.

Check the fuel tank and see that the shutoff valve

is open.

2.

Remove the fuel line from the transfer pump

outlet and work the priming lever on the pump.

Fuel should spurt out of the pump. If not, remove

the pump for repair or replacement.

Testing

If the transfer pump delivers

fuel,

test it with a

pressure gauge or manometer. Perform these tests

before removing the pump from the engine. Remove

the pump outlet and install the pressure gauge. See

Figure 15.

Test the valves and diaphragm by operating the

primer lever a few times and watching the pressure. It

should not drop off rapidly after priming has stopped.

Next run the engine at governed speed on fuel

provided by gravity feed and measure the fuel pump

pressure developed. Pressure should be between 5

and 6 psi with the gauge 16 inches above the fuel

pump.

A low pressure reading indicates extreme wear in one

part or some wear

in

all parts, and the pump should be

overhauled or replaced. If the reading is above

maximum, the diaphragm is probably too tight or the

diaphragm spring too strong. This can also be caused

byfuel seeping underthediaphragm retainer nut and

between the diaphragm layers, causing a bulge in the

diaphragm. Overhaul the pump and replace the

defective parts. See Figure 16.

Low pressure with little or no pressure leak after

pumping stops indicates a weak or broken spring or

worn linkage and in most cases the pump should be

replaced.

Repair

Transfer pump failure is usually due to a leaking

diaphragm, valve or valve gasket. A kit is available for

replacement of various parts. Because the extent of

wear cannot be detected by the eye, replace all parts

in the kit. If the diaphragm is broken or leaks, check

for diluted crankcase oil and replace.

Occasionally, failureisduetoabrokenorweak spring

or wear in the linkage. In this case, replace the worn

parts or install a new pump. Obtain replacement parts

or install a new pump. Obtain replacement parts other

than the repair kit from an original equipment parts

distributor.

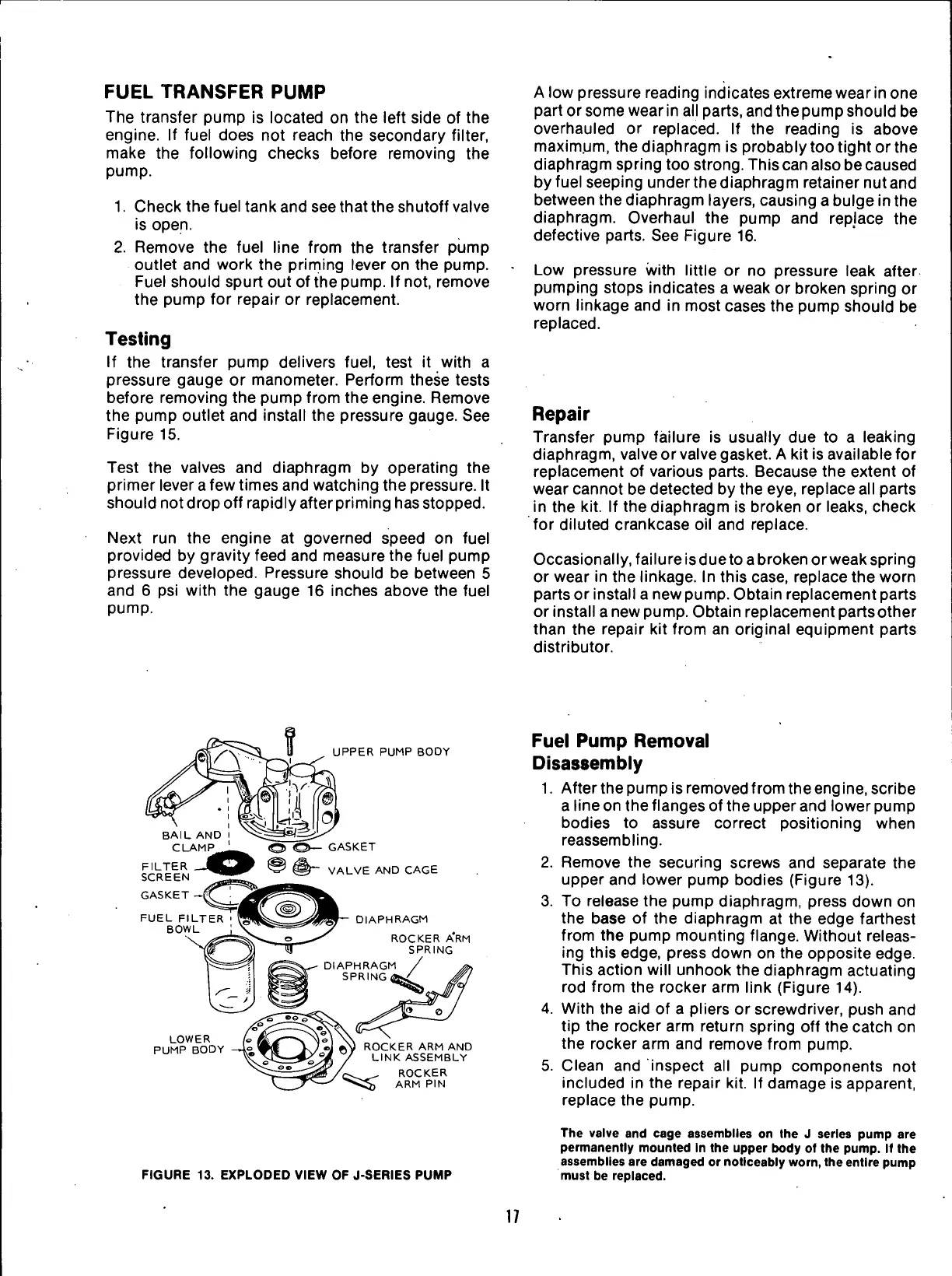

UPPER PUMP BODY

GASKET

VALVE AND CAGE

DIAPHRAGM

ROCKER ARM

SPRING

DIAPHRAGM

SPRING

LOWER

PUMP BODY

ftV ROCKER ARM AND

7

LINK ASSEMBLY

t „ ROCKER

>,

^$ ARM PIN

FIGURE 13. EXPLODED VIEW OF J-SERIES PUMP

Fuel

Pump Removal

Disassembly

1.

After the pump is removed from the eng

ine,

scribe

a line on the flanges of the upper and lower pump

bodies to assure correct positioning when

reassembling.

2.

Remove the securing screws and separate the

upper and lower pump bodies (Figure 13).

3. To release the pump diaphragm, press down on

the base of the diaphragm at the edge farthest

from the pump mounting flange. Without releas-

ing this edge, press down on the opposite edge.

This action will unhook the diaphragm actuating

rod from the rocker arm link (Figure 14).

4.

With the aid of a pliers or screwdriver, push and

tip the rocker arm return spring off the catch on

the rocker arm and remove from pump.

5. Clean and inspect all pump components not

included in the repair kit. If damage is apparent,

replace the pump.

The valve and cage assemblies on Ihe J series pump are

permanently mounted in the upper body of the pump. If the

assemblies are damaged or noticeably worn, theentire pump

must be replaced.

17

Loading...

Loading...