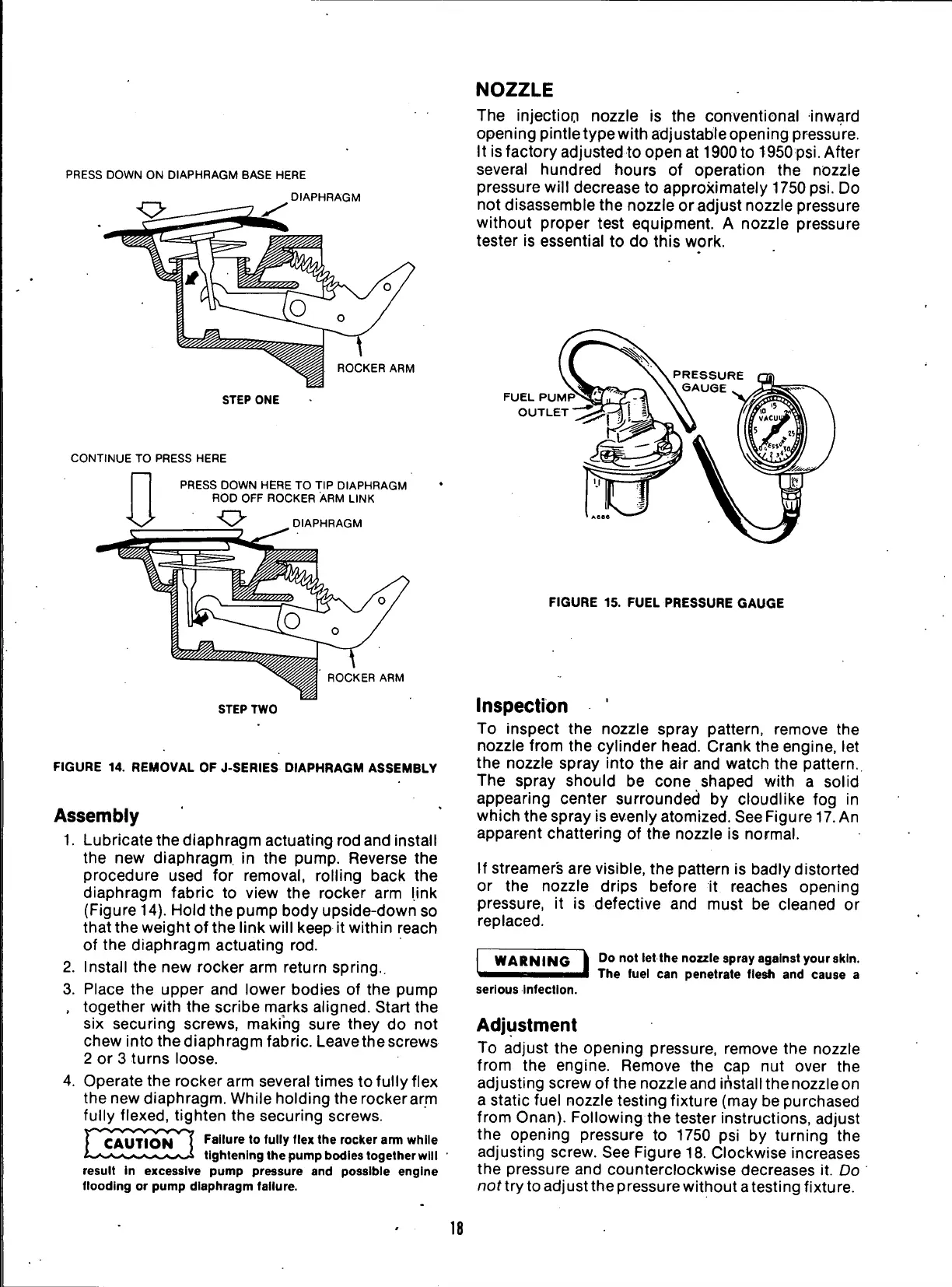

PRESS DOWN ON DIAPHRAGM BASE HERE

DIAPHRAGM

ROCKER ARM

STEP ONE

CONTINUE TO PRESS HERE

PRESS DOWN HERE TO TIP DIAPHRAGM

ROD OFF ROCKER ARM LINK

DIAPHRAGM

ROCKER ARM

STEP TWO

FIGURE 14. REMOVAL OF J-SERIES DIAPHRAGM ASSEMBLY

Assembly

1.

Lubricate the diaphragm actuating rod and install

the new diaphragm in the pump. Reverse the

procedure used for removal, rolling back the

diaphragm fabric to view the rocker arm link

(Figure 14). Hold the pump body upside-down so

that the weight of the link will keep it within reach

of the diaphragm actuating rod.

2.

Install the new rocker arm return spring..

3. Place the upper and lower bodies of the pump

, together with the scribe marks aligned. Start the

six securing screws, making sure they do not

chew into the diaphragm fabric. Leave the screws

2 or 3 turns loose.

4.

Operate the rocker arm several times to fully flex

the new diaphragm. While holding the rockerarm

fully flexed, tighten the securing screws.

Failure to fully flex the rocker arm while

tightening the pump bodies together will

result in excessive pump pressure and possible engine

flooding or pump diaphragm failure.

CAUTION

NOZZLE

The injection nozzle is the conventional inward

opening pintletypewith adjustable opening pressure.

It is factory adjusted to open at 1900 to 1950

psi.

After

several hundred hours of operation the nozzle

pressure will decrease to approximately 1750 psi. Do

not disassemble the nozzle oradjust nozzle pressure

without proper test equipment. A nozzle pressure

tester is essential to do this work.

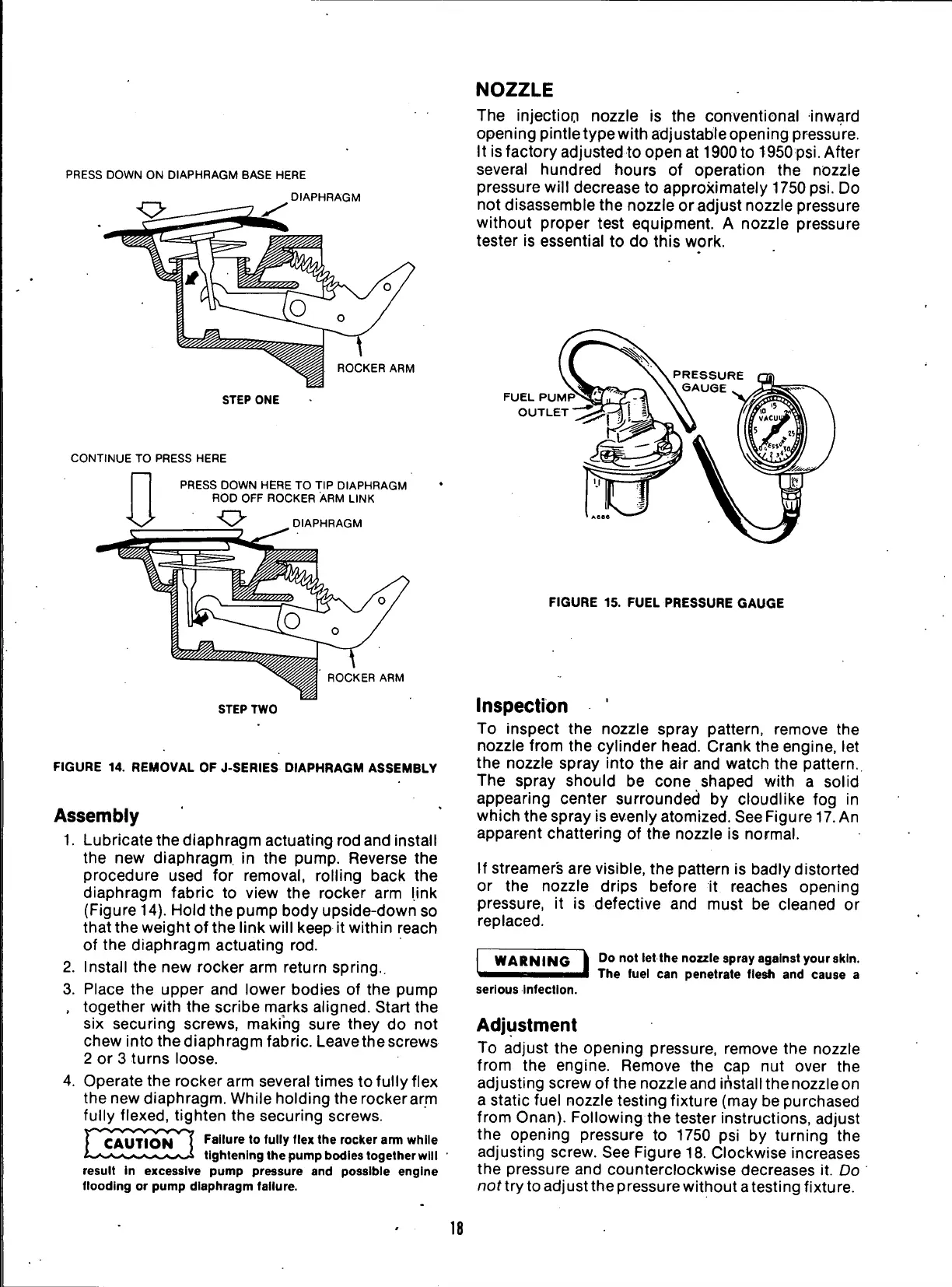

FUEL PUMP

1

OUTLET

FIGURE 15. FUEL PRESSURE GAUGE

Inspection

To inspect the nozzle spray pattern, remove the

nozzle from the cylinder head. Crank the engine, let

the nozzle spray into the air and watch the pattern.

The spray should be cone shaped with a solid

appearing center surrounded by cloudlike fog in

which the spray is evenly atomized. See Figure

17.

An

apparent chattering of the nozzle is normal.

If streamer's are visible, the pattern is badly distorted

or the nozzle drips before it reaches opening

pressure, it is defective and must be cleaned or

replaced.

WARNING

serious infection.

Do not let the nozzle spray against your

skin.

The fuel can penetrate flesh and cause a

Adjustment

To adjust the opening pressure, remove the nozzle

from the engine. Remove the cap nut over the

adjusting screw ofthe nozzle and installthenozzleon

a static fuel nozzle testing fixture (may be purchased

from Onan). Following the tester instructions, adjust

the opening pressure to 1750 psi by turning the

adjusting screw. See Figure 18. Clockwise increases

the pressure and counterclockwise decreases it. Do

not try to

adj

ust the pressure without

a

testi

ng

f ixtu

re.

18

Loading...

Loading...