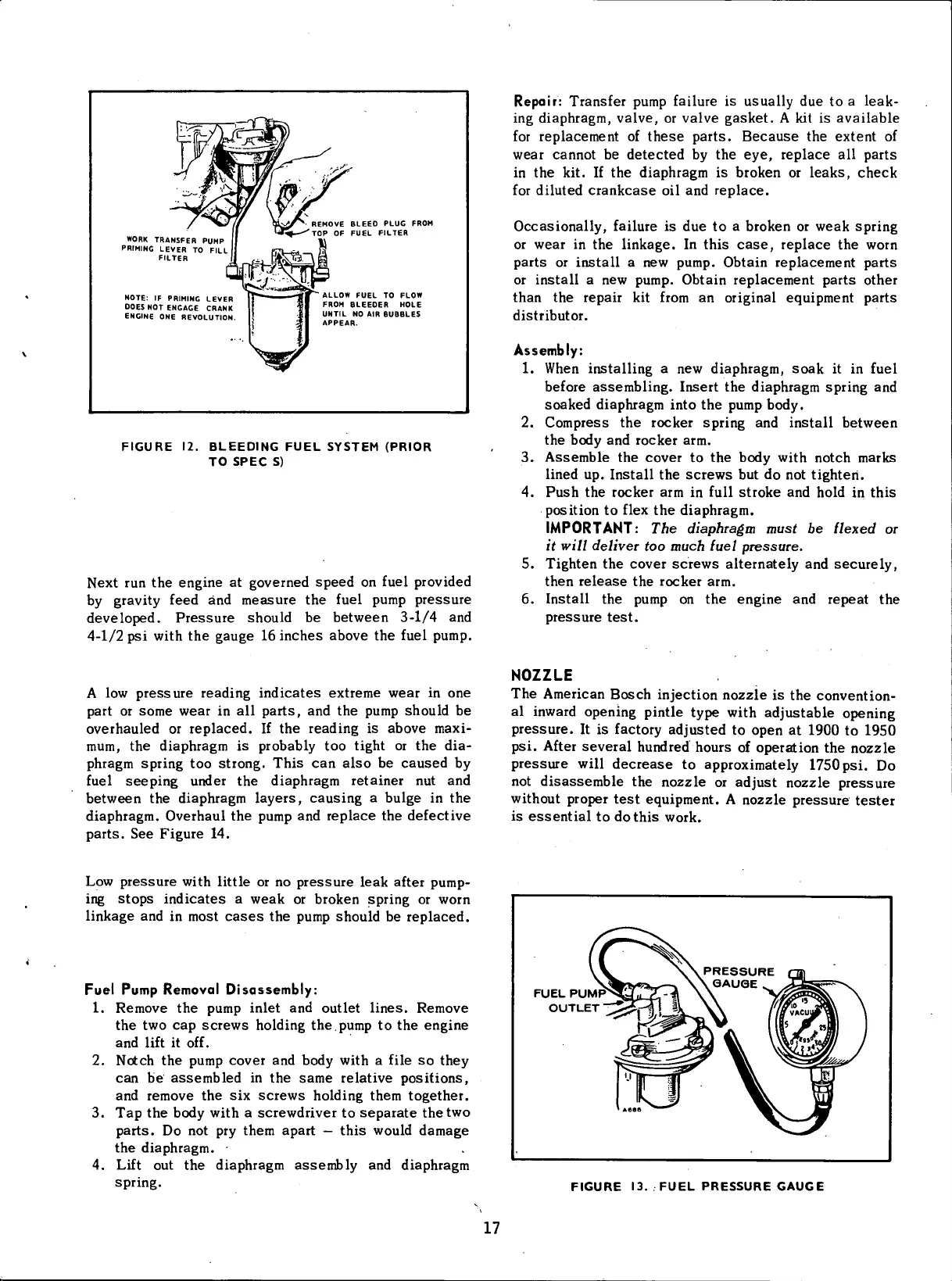

WORK

TRANSFER

PUMP

PRIMING

LEVER TO

FILL

FILTER

NOTE: IF

PRIMING

LEVER

DOES

NOT

ENGAGE

CRANK

ENGINE

ONE REVOLUTION

REMOVE

BLEED PLUG

FROM

TOP OF FUEL

FILTER

ALLOW

FUEL TO

FLOW

FROM

BLEEDER

HOLE

UNTIL

NO

AIR

BUBBLES

APPEAR.

FIGURE

12.

BLEEDING

FUEL

SYSTEM

(PRIOR

TO

SPEC

S)

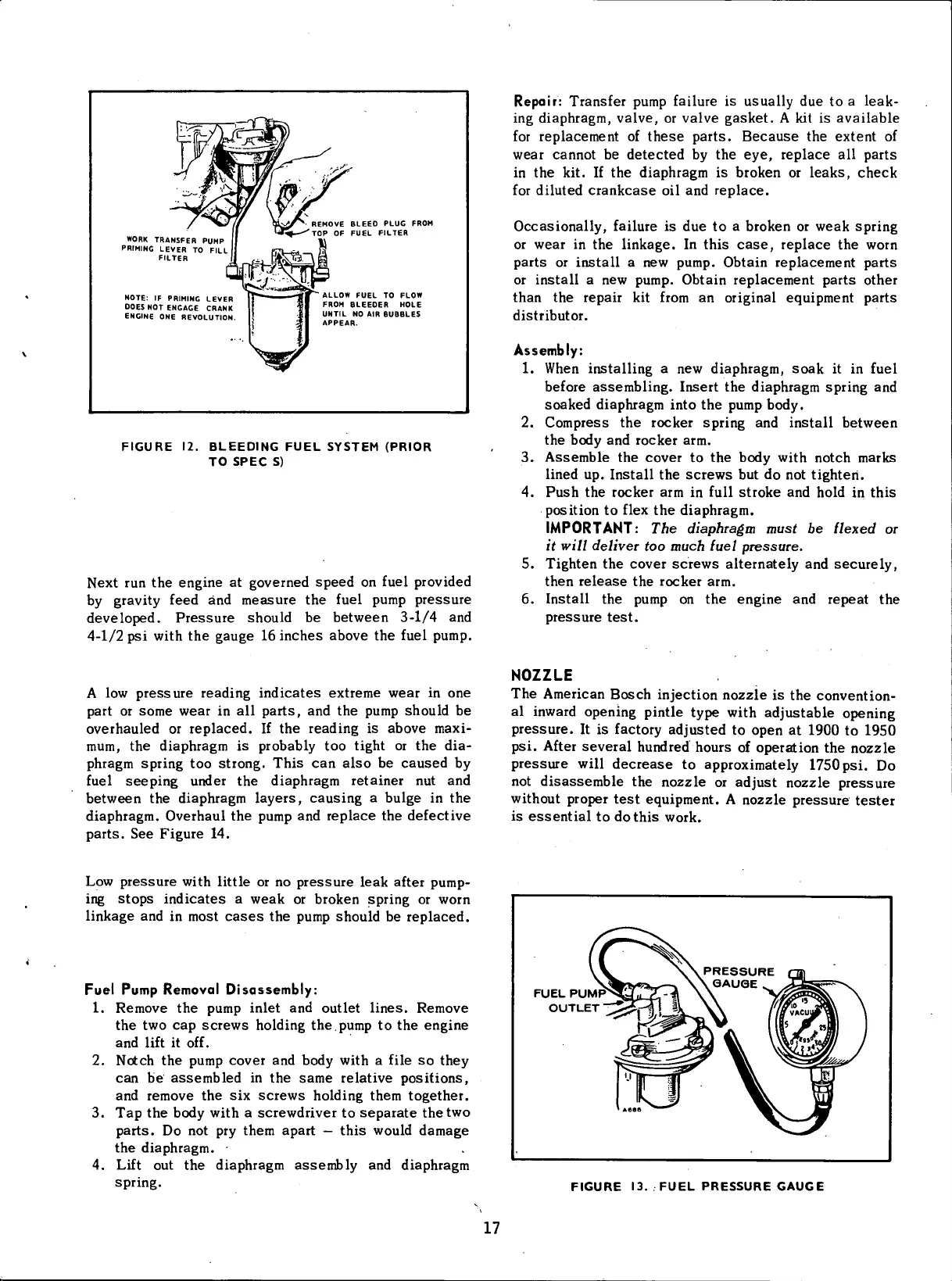

Next

run the engine at governed

speed

on

fuel

provided

by

gravity feed and

measure

the

fuel

pump

pressure

developed.

Pressure

should be between 3-1/4 and

4-1/2 psi

with

the

gauge

16 inches above the

fuel

pump.

Repair: Transfer pump failure is usually due to a leak-

ing

diaphragm, valve, or valve

gasket.

A kit is available

for

replacement of

these

parts.

Because

the extent of

wear cannot be detected by the eye, replace all parts

in

the kit. If the diaphragm is broken or leaks, check

for

diluted

crankcase

oil and replace.

Occasionally,

failure is due to a broken or weak spring

or

wear in the linkage. In this

case,

replace the

worn

parts or

install

a new pump. Obtain replacement parts

or

install

a new pump. Obtain replacement parts other

than the repair kit

from

an

original

equipment parts

distributor.

Assembly:

1.

When

installing

a new diaphragm,

soak

it in

fuel

before assembling. Insert the diaphragm spring and

soaked diaphragm into the pump body.

2.

Compress the rocker spring and

install

between

the body and rocker arm.

3. Assemble the cover to the body

with

notch marks

lined

up.

Install

the screws but do not tighten.

4.

Push the rocker arm in

full

stroke and

hold

in this

position

to

flex

the diaphragm.

IMPORTANT:

The

diaphragm must

be

flexed

or

it

will deliver

too

much fuel pressure.

5. Tighten the cover screws alternately and securely,

then

release

the rocker arm.

6.

Install

the pump on the engine and

repeat

the

pressure

test.

A

low

pressure

reading indicates extreme wear in one

part or

some

wear in all parts, and the pump should be

overhauled or replaced. If the reading is above

maxi-

mum,

the diaphragm is probably too

tight

or the dia-

phragm spring too strong. This can also be

caused

by

fuel

seeping under the diaphragm retainer nut and

between the diaphragm layers, causing a bulge in the

diaphragm. Overhaul the pump and replace the defective

parts. See Figure 14.

NOZZLE

The American Bosch

injection

nozzle is the convention-

al

inward

opening pintle type

with

adjustable opening

pressure.

It is factory adjusted to open at 1900 to 1950

psi.

After

several hundred hours of operation the nozzle

pressure

will

decrease

to approximately

1750 psi.

Do

not

disassemble

the nozzle or adjust nozzle

pressure

without

proper

test

equipment. A nozzle

pressure

tester

is

essential to

do

this

work.

Low

pressure

with

little

or no

pressure

leak after pump-

ing

stops

indicates a weak or broken spring or

worn

linkage

and in most

cases

the pump should be replaced.

Fuel

Pump Removal Disassembly:

1.

Remove the pump

inlet

and outlet lines. Remove

the two cap screws holding the.

pump

to the engine

and

lift

it off.

2.

Notch the pump cover and body

with

a

file

so they

can be assembled in the

same

relative positions,

and remove the six screws holding them together.

3. Tap the body

with

a screwdriver to

separate

the

two

parts. Do not pry them apart

—

this

would

damage

the diaphragm. -

4. Lift

out the diaphragm assembly and diaphragm

spring.

FUEL

PUMP

OUTLET

FIGURE

13.

FUEL

PRESSURE

GAUGE

17

Loading...

Loading...