COVER

DIAPHRAGM

ASSEMBLY-

71}

DIAPHRAGM

SPRING

—

VALVE

AND

CAGE

ASSEMBLIES

ROCKER

ARM

SPRING-

FILTER

SCREEN

ROCKER

nC

ARM

PIN

ROCKER

ARM-

BODY-

PRIMING

LEVER

A687

ROCKER

ARM

LINK

FILTER

BOWL

FIGURE

14.

FUEL TRANSFER

PUMP

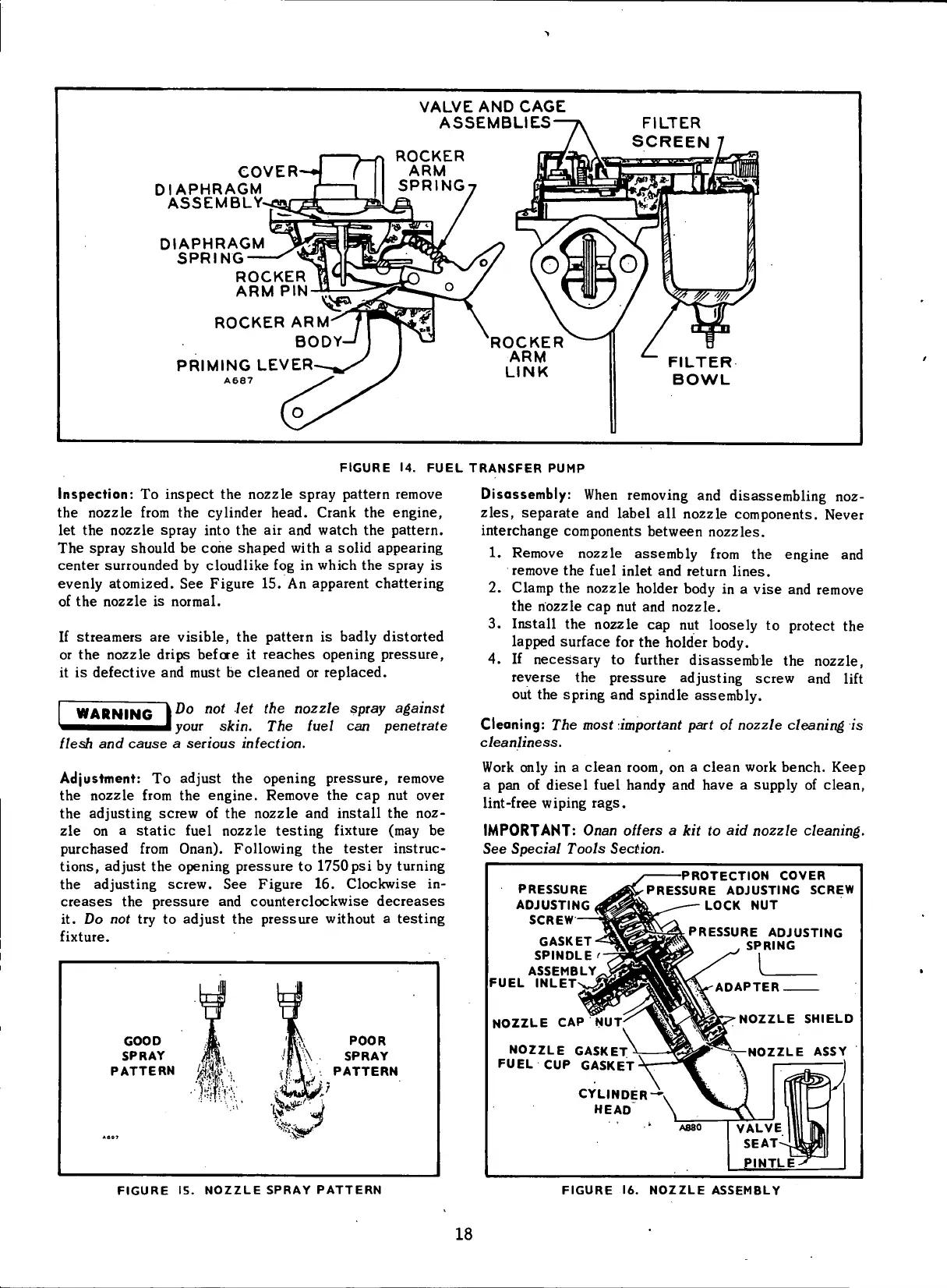

Inspection:

To inspect the nozzle spray pattern remove

the nozzle

from

the cylinder head. Crank the engine,

let

the nozzle spray

into

the air and watch the pattern.

The spray should be cone shaped

with

a

solid

appearing

center surrounded by

cloudlike

fog

in

which

the spray is

evenly

atomized. See Figure 15. An apparent chattering

of

the nozzle is normal.

If

streamers

are

visible,

the pattern is badly distorted

or

the nozzle drips before it

reaches

opening

pressure,

it

is defective and must be cleaned or replaced.

WARNING

I

Do

not let the

nozzle spray against

your skin.

The

iuel

can

penetrate

flesh

and

cause

a

serious infection.

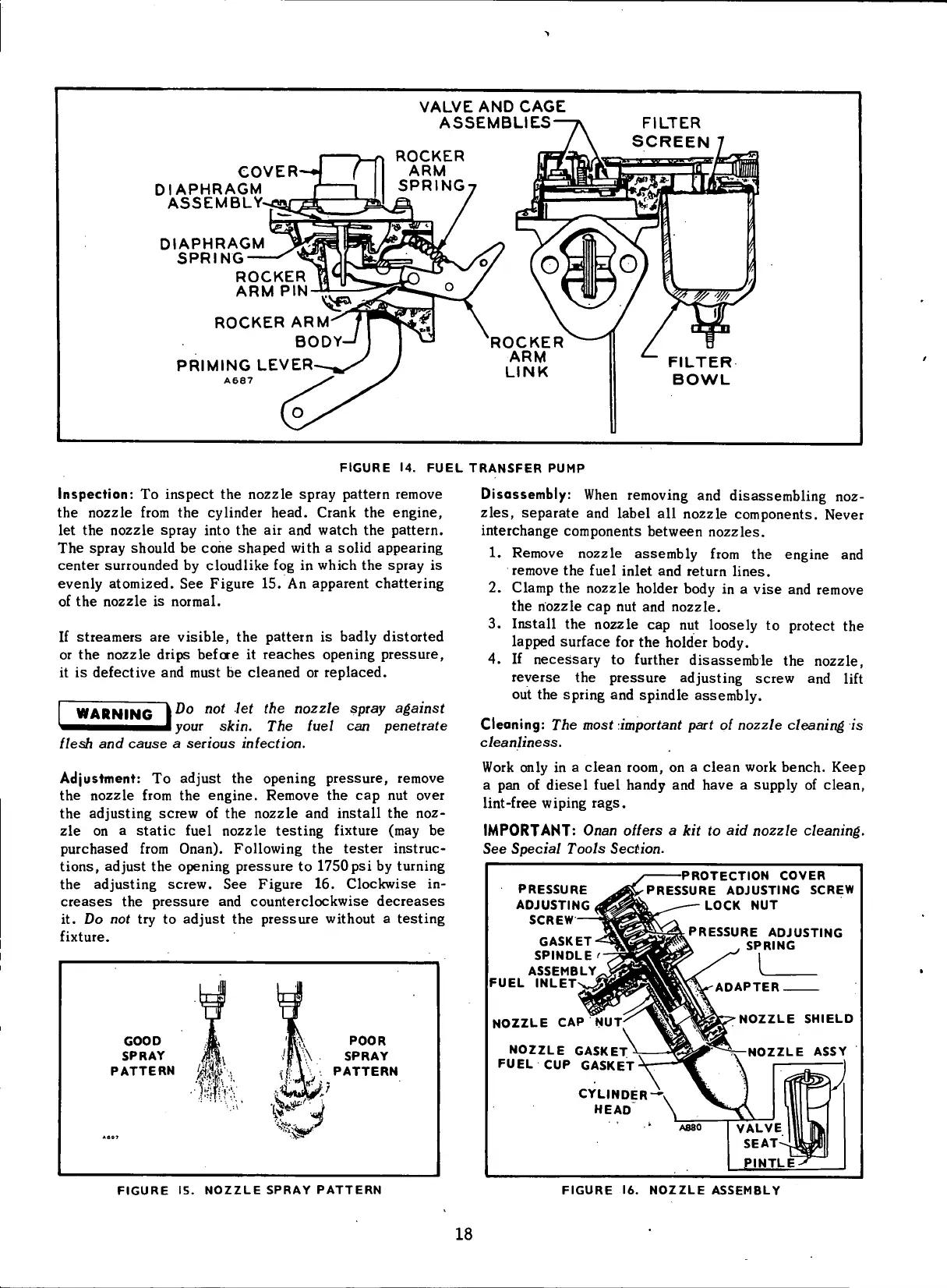

Adjustment:

To adjust the opening

pressure,

remove

the nozzle

from

the engine. Remove the cap nut over

the adjusting screw of the nozzle and

install

the noz-

zle

on a static

fuel

nozzle testing

fixture

(may be

purchased

from

Onan).

Following

the

tester

instruc-

tions,

adjust the opening

pressure

to

1750

psi by

turning

the adjusting screw. See Figure 16. Clockwise in-

creases

the

pressure

and counterclockwise

decreases

it.

Do not try to adjust the

pressure

without

a testing

fixture.

GOOD

if

m

POOR

SPRAY

J

|y\ SPRAY

PATTERN

;

V

PATTERN

•

:

m..

AOOT

**

Disassembly: When removing and disassembling noz-

zles,

separate

and label all nozzle components. Never

interchange components between nozzles.

1.

Remove nozzle assembly

from

the engine and

remove the

fuel

inlet

and return lines.

2.

Clamp the nozzle holder body in a vise and remove

the nozzle cap nut and nozzle.

3.

Install

the nozzle cap nut loosely to protect the

lapped surface for the holder body.

4.

If

necessary

to further disassemble the nozzle,

reverse the

pressure

adjusting screw and

lift

out

the spring and spindle assembly.

Cleaning:

The

most important part

of

nozzle cleaning

is

cleanliness.

Work

only

in a clean room, on a clean

work

bench. Keep

a pan of diesel

fuel

handy and have a supply of clean,

lint-free

wiping

rags.

IMPORTANT: Onan offers

a kit

to aid

nozzle cleaning.

See

Special Tools Section.

PRESSURE

ADJUSTING

SCREW—

GASKET

SPINDLE

'

ASSEMBLY

FUEL

INLET

•ROTECTION COVER

-PRESSURE

ADJUSTING SCREW

LOCK

NUT

^PRESSURE

ADJUSTING

SPRING

NOZZLE

CAP NUT;

NOZZLE GASKET

FUEL

CUP

GASKET

NOZZLE SHIELD

NOZZLE ASSY

CYLINDER—v

HEAD

\

P'NTLE

FIGURE

15.

NOZZLE SPRAY PATTERN

FIGURE

16.

NOZZLE ASSEMBLY

18

Loading...

Loading...