Never

use hard or

sharp

tools, emery

paper,

grinding

powder or abrasives of any

kind.

Soak each nozzle in

fuel

to loosen

dirt.

Then clean the

inside

with

a small strip of

wood

soaked in oil and the

spray hole

with

a

wood

splinter. If

necessary,

clean the

outer surfaces of the nozzle body

with

a

brass

brush but

do not attempt to

scrape

carbon

from

the nozzle sur-

faces. This can severely

damage

the spray hole. Use a

soft

oil-soaked rag or mutton

tallow

and

felt

to clean

the nozzle valve.

Repair: If cleaning

will

not eliminate a nozzle defect,

replace the nozzle or take it to an authorized service

station.

Do not attempt to replace nozzle parts except

for

the nozzle and pintle assembly.

Assembly:

Rinse both the valve and nozzle thoroughly

before assembly and coat

with

oil. The valve must be

free in the nozzle.

Lift

it about 1/3 way out of the

body.

It should slide back to its

seat

without

aid when

the assembly is held at a

45°

angle. If

necessary,

work

the valve

into

its body

with

clean mutton

tallow.

1.

Remove all

pressure

on the nozzle spring by

adjusting

the

pressure

adjusting screw.

2.

Clamp the nozzle holder body in a vise.

3. Set the valve in the body and set the nozzle over

it.

4.

Install

the nozzle cap nut loosely.

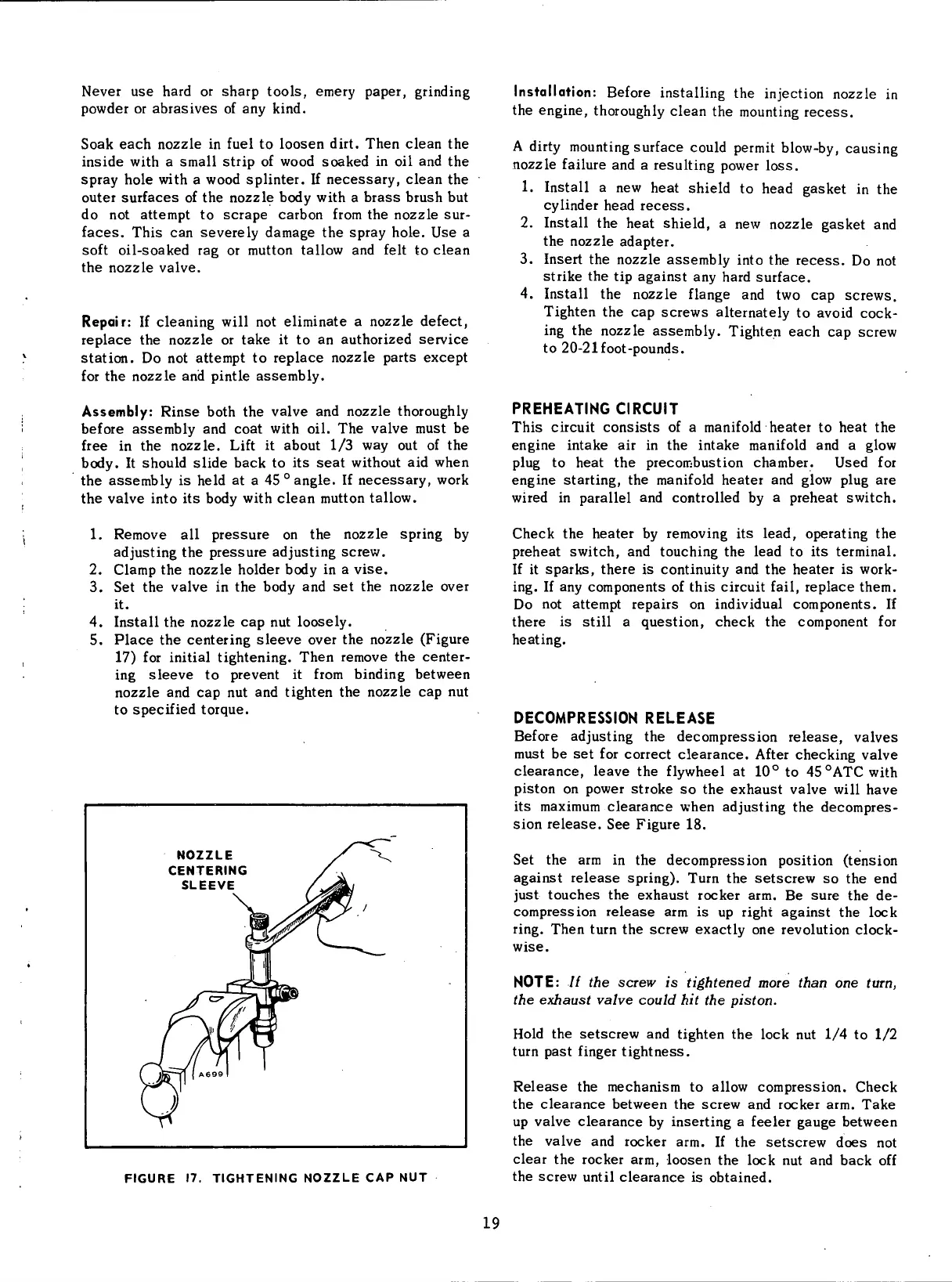

5. Place the centering sleeve over the nozzle (Figure

17)

for

initial

tightening. Then remove the center-

ing

sleeve to prevent it

from

binding

between

nozzle and cap nut and tighten the nozzle cap nut

to

specified torque.

NOZZLE

CENTERING

SLEEVE

FIGURE

17.

TIGHTENING

NOZZLE

CAP NUT

Installation:

Before

installing

the

injection

nozzle in

the engine, thoroughly clean the mounting

recess.

A

dirty

mounting

surface

could

permit

blow-by,

causing

nozzle

failure

and a resulting power loss.

1.

Install

a new

heat

shield to head gasket in the

cylinder

head

recess.

2.

Install

the

heat

shield, a new nozzle gasket and

the nozzle

adapter.

3. Insert the nozzle assembly

into

the

recess.

Do not

strike

the tip against any hard surface.

4.

Install

the nozzle flange and two cap screws.

Tighten

the cap screws alternately to

avoid

cock-

ing

the nozzle assembly. Tighten each cap screw

to 20-21

foot-pounds.

PREHEATING

CIRCUIT

This

circuit

consists of a

manifold

heater

to

heat

the

engine intake air in the intake

manifold

and a

glow

plug

to

heat

the precombustion chamber. Used for

engine starting, the

manifold

heater

and

glow

plug

are

wired

in parallel and controlled by a preheat

switch.

Check the

heater

by removing its lead, operating the

preheat

switch,

and touching the lead to its terminal.

If

it sparks, there is

continuity

and the

heater

is

work-

ing.

If any components of this

circuit

fail,

replace them.

Do

not attempt repairs on

individual

components. If

there is

still

a question, check the component for

heating.

DECOMPRESSION

RELEASE

Before

adjusting the decompression

release,

valves

must be set for correct clearance.

After

checking valve

clearance, leave the

flywheel

at 10° to

45

0

ATC

with

piston

on power stroke so the exhaust valve

will

have

its

maximum clearance when adjusting the decompres-

sion

release.

See Figure 18.

Set the arm in the decompression position (tension

against

release

spring).

Turn

the setscrew so the end

just

touches the exhaust rocker arm. Be

sure

the de-

compression

release

arm is up

right

against the

lock

ring.

Then

turn

the screw exactly one

revolution

clock-

wise.

NOTE:

// the

screw

is

tightened more than

one

turn,

the

exhaust valve could

hit the

piston.

Hold

the setscrew and tighten the

lock

nut 1/4 to 1/2

turn

past

finger tightness.

Release

the mechanism to

allow

compression. Check

the clearance between the screw and rocker arm. Take

up valve clearance by inserting a feeler

gauge

between

the valve and rocker arm. If the setscrew

does

not

clear the rocker arm, loosen the

lock

nut and back off

the screw

until

clearance is obtained.

19

Loading...

Loading...