10-4

VT1037-2s

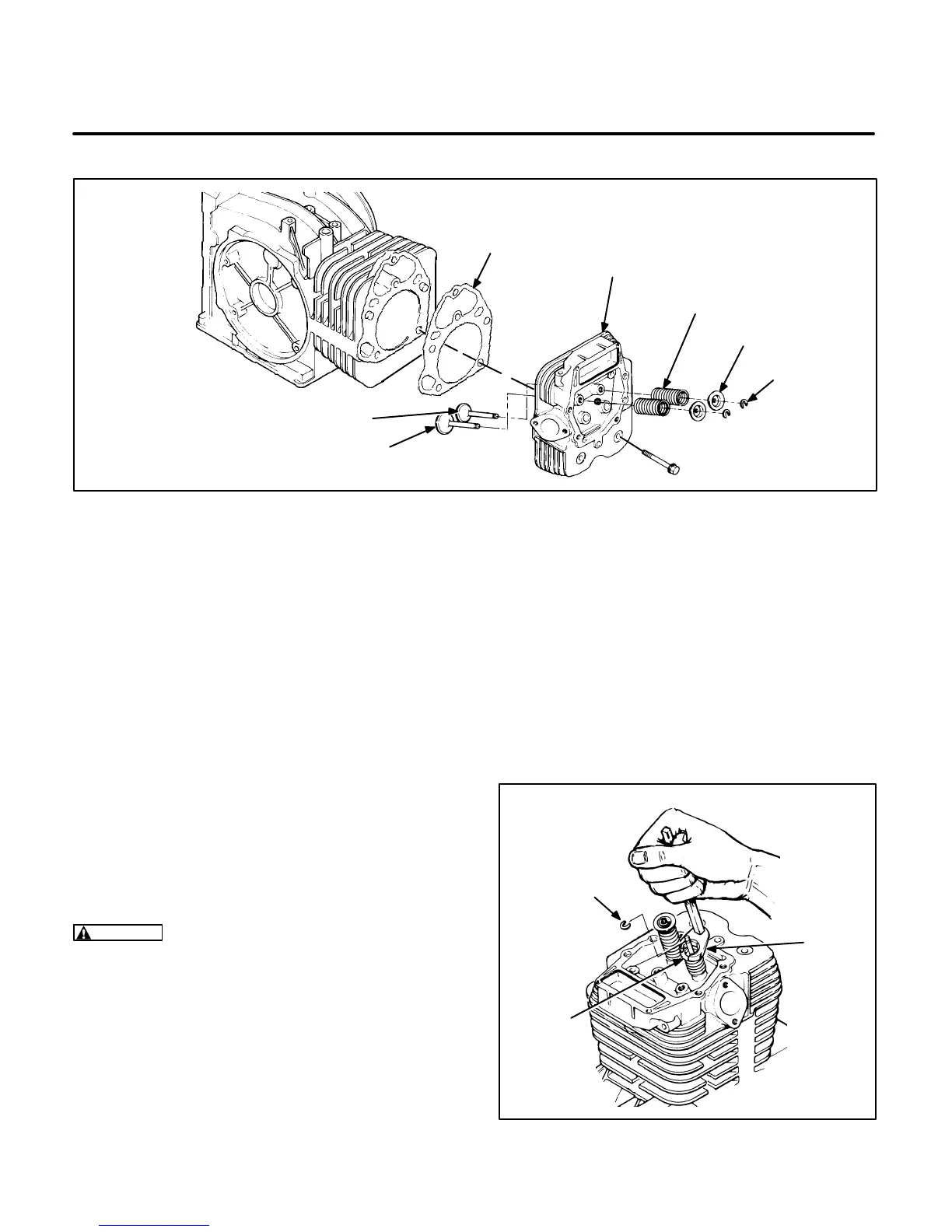

RETAINERS

CYLINDER

HEAD

EXHAUST

VALVE

VALVE

SPRINGS

GASKET

KEEPERS

INTAKE

VALVE

FIGURE 10-6. OVERHEAD VALVE SYSTEM

VALVE SYSTEM

This engine uses an overhead valve design, as

shown in Figure 10-6. A properly functioning valve

system is essential for good engine performance.

Access to the valve system is gained by removing

the head cover and cylinder head. Use the following

procedures to inspect and service the valve system.

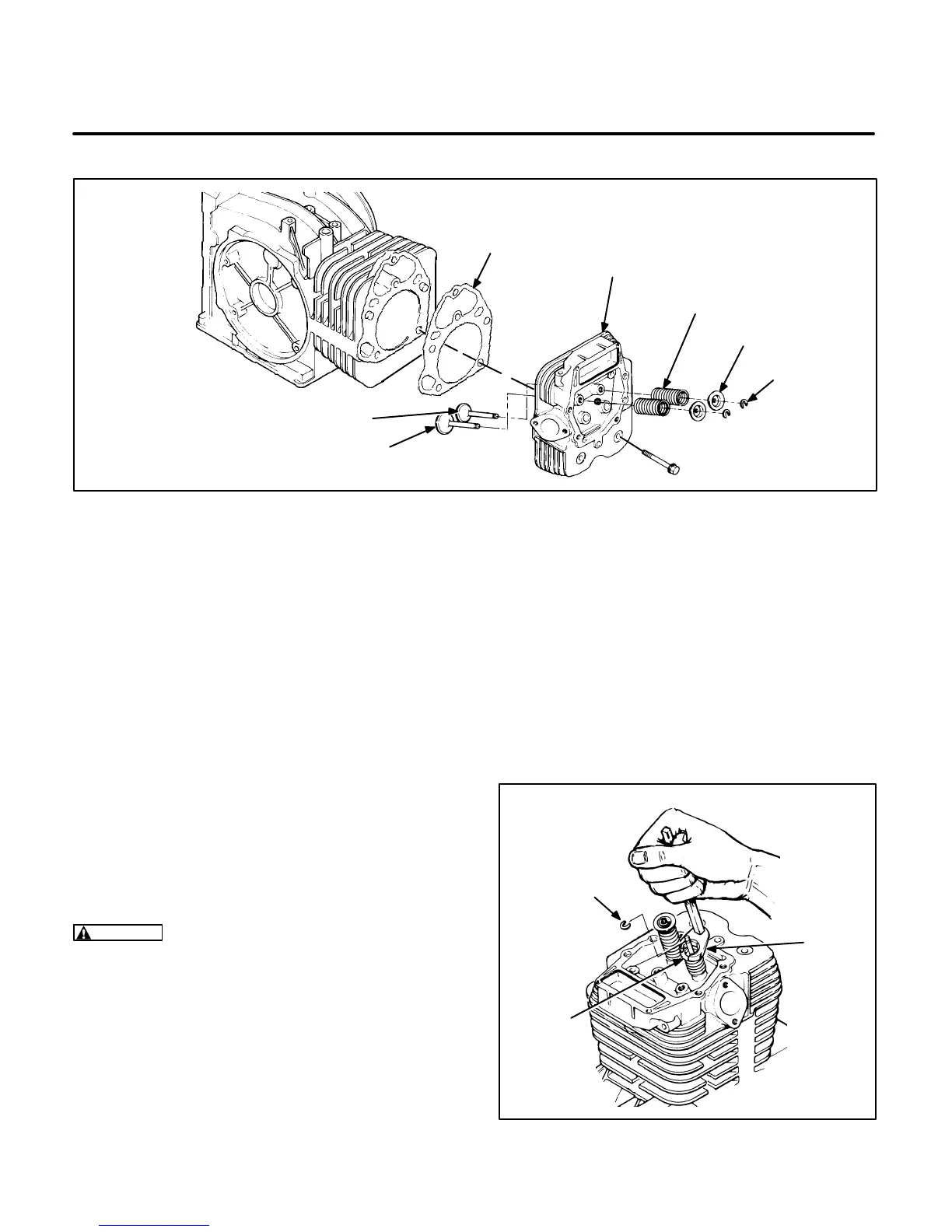

Valve Removal

The intake and exhaust valves can be removed

from the cylinder head without the use of special

tools. Depress the valve spring retainer using a 9/16

inch crows foot on a 6 inch extension, then remove

the keeper (Figure 10-7). Remove the spring retain-

er, spring and valve.

WARNING

Always wear safety glasses with

side shields when removing springs to prevent

severe eye damage.

Inspection

Valve Face:

Check the valve face for evidence of

burning, warping, out-of-round, and carbon depos-

its (see Figure 10-8 on Page 10-5).

Burning and pitting are caused by the valve failing to

seat tightly. This condition is often caused by hard

carbon particles on the seat. It may also be due to

weak valve springs, insufficient tappet clearance,

warping, and misalignment.

Warping occurs mainly due to exposure to intense

heat. Out-of-round wear follows when the seat is

pounded by a valve whose head is not in line with

the stem and guide. If a valve face is burned or

warped, or the stem worn, install a new one.

VT1038-1s

KEEPER

9/16 INCH

CROWS

FOOT

RETAINER

FIGURE 10-7. VALVE REMOVAL

Loading...

Loading...