10-10

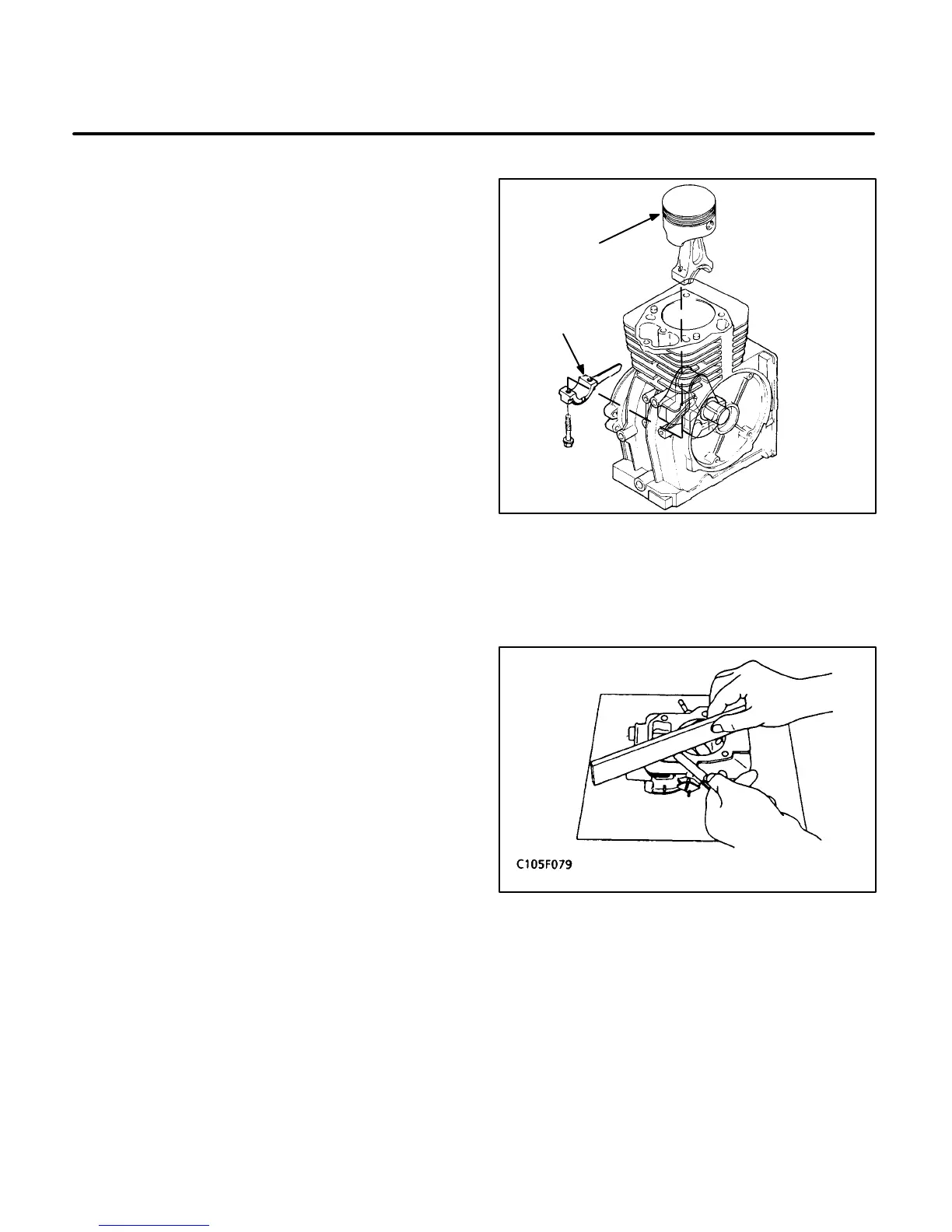

1. Remove the two bolts from the connecting rod

cap. Mark direction of assembly for connecting

the rod, cap, and splasher.

2. Remove the rod cap from the rod and push the

piston assembly out the top of the cylinder (Fig-

ure 10-18). Be careful not to scratch the crank

pin or the cylinder wall when removing the pis-

ton.

3. Carefully pull the crankshaft out of the oil seal

and bearing.

INSPECTION OF ENGINE PARTS

The following section describes procedures for in-

specting each of the major engine components.

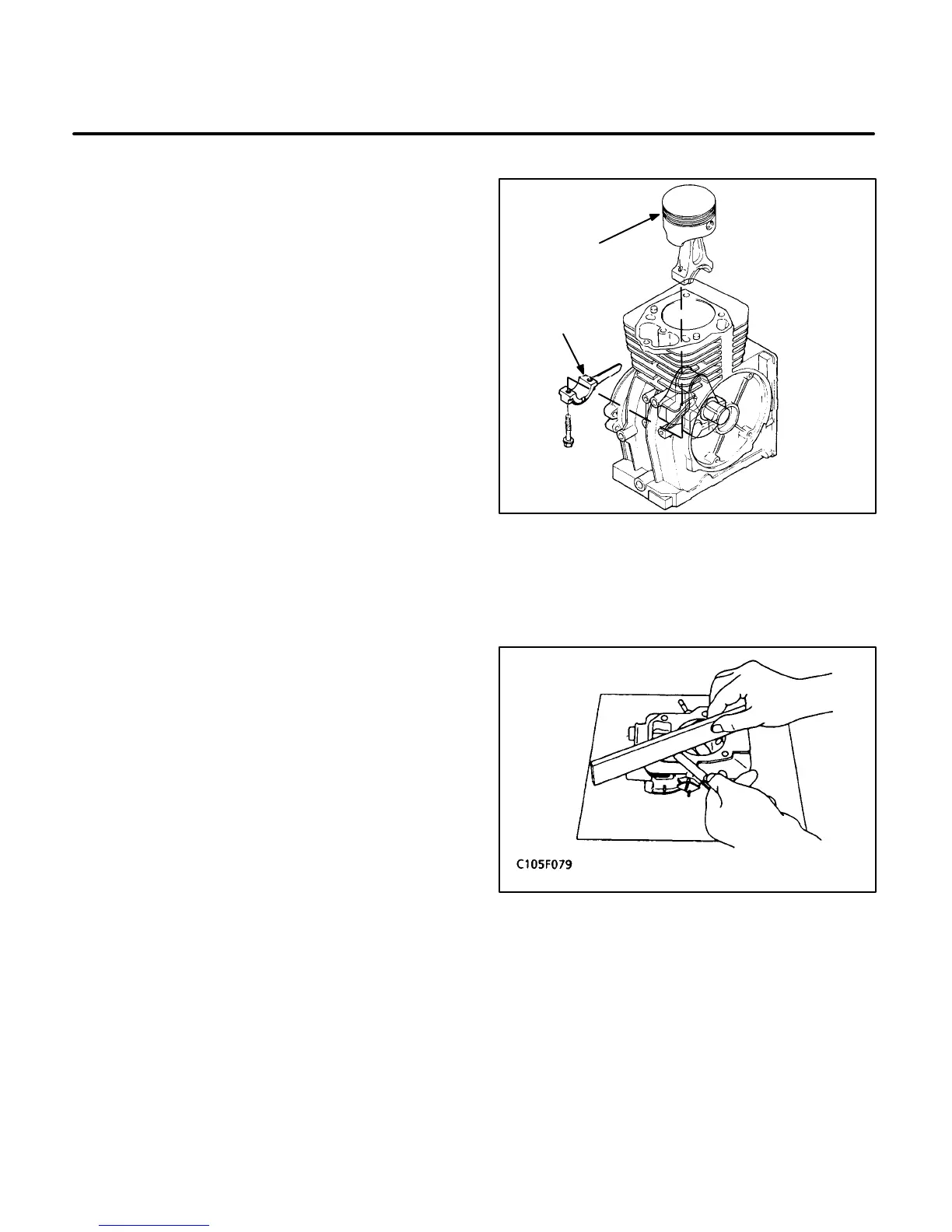

Cylinder Head

1. Clean the cylinder head surface.

2. Place a straight edge on the top of the cylinder

head as shown in Figure 10-19. Use a feeler

gauge to measure the amount of distortion.

3. If the measurement exceeds the specified limit,

replace the cylinder head (see Section

3.

Di-

mensions and Clearances

).

Cylinder Block

Cleaning:

After removing the piston, crankshaft,

cylinder head; etc., inspect the block for cracks and

extreme wear. If the block is still serviceable, pre-

pare it for cleaning as follows:

1. Scrape all of the old gasket material from the

block.

2. Remove grease and scale from the cylinder

block by agitating in a bath of commercial

cleaning solution or hot soapy washing solu-

tion.

3. Rinse block in clean hot water to remove clean-

ing solution.

C1134-1s

PISTON

ROD CAP

FIGURE 10-18. PISTON REMOVAL

FIGURE 10-19. CYLINDER HEAD SURFACE

FLATNESS

Loading...

Loading...