Maintenance

Version 1.2.4 - 2022-10-2640 Translation of original instruction

S275N | S275NV

EN

S275N_S275NV_GB_5.fm

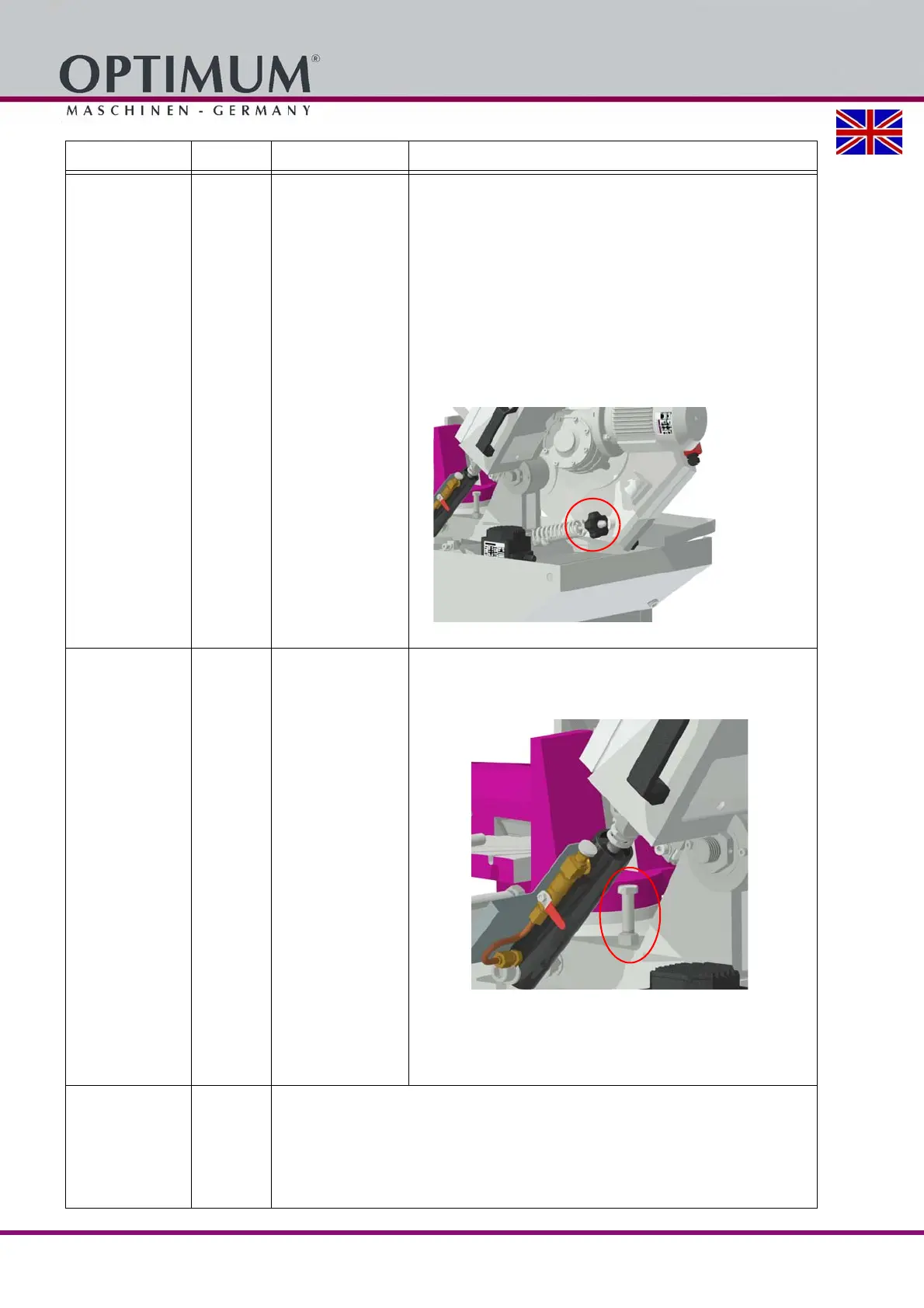

If crooked cuts

are occurring, if

teeth break out,

if the belt

guidance rollers

are deformed or

breaking.

Saw arch

Adjusting of the

saw arch pressure

Place the saw arch in the upper position and close

the stop cock on the hydraulic cylinder.

Place a weighing machine in the work-holder vice.

Let the saw arch descend slowly.

Fully open the stop cock on the hydraulic cylinder

once the saw belt has made contact with the

weighing machine.

The support force of the saw arch on the weighing

machine should come to 15 - 16 kg.

If necessary, correct the value by changing the

position of the spring using the adjusting screw.

Img.5-3: Saw arch pressure

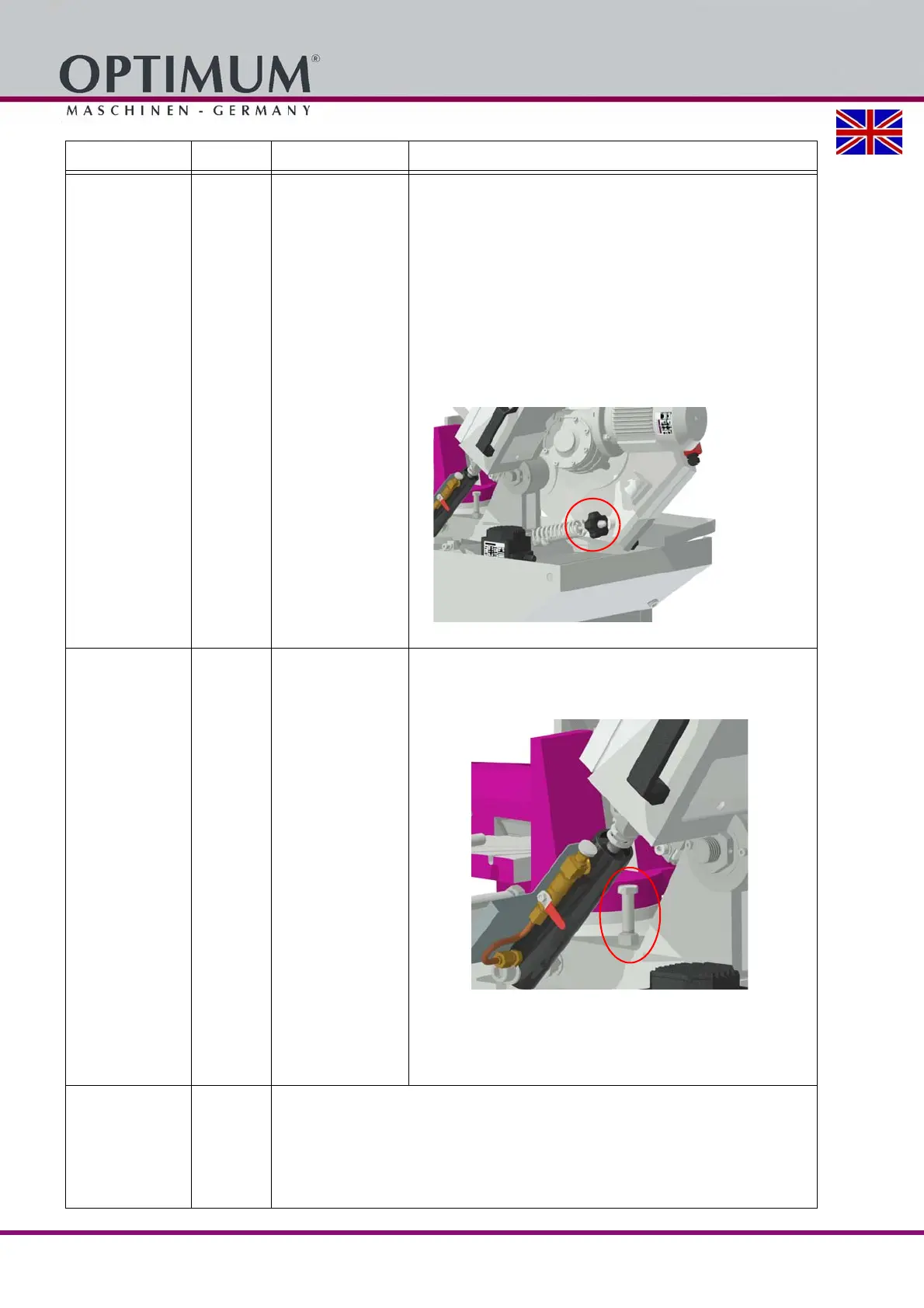

If the metal band

saw and the

cooling pump

continue to

operate after the

sawing process

is complete.

If the metal band

saw and the

cooling pump

switch off before

sawing is

terminated.

Adjusting the end

stop switch

Turn the screw on the end stop switch up or down so

that it comes into contact with the end stop switch

when the sawing process finishes.

Img.5-4: End stop switch

Check the end position of the saw arch. The end

position of the saw arch must correspond to the

switching-off of the end stop switch.

Start of shift

after every

maintenance or

repair work

metal band saw

Safety check on page 12

Interval Where? What? How?

Loading...

Loading...