Maintenance

Version 1.2.4 - 2022-10-26 41Translation of original instruction

S275N | S275NV EN

S275N_S275NV_GB_5.fm

Weekly

Drive shaft

Bearing

Oiling

every month

Worm gear

Inspection

INFORMATION

During the first few days in service, the helical gear

may become quite hot. If the temperature does not

exceed 70ºC, no further measures need be taken.

This running-in process can improve considerably if

a little Molykote G gear paste is added to the oil in

the helical gear before the machine is first used.

This reduces wear in the flanks of the teeth and

increases the useful service life of the gear.

As required

Machine vice

Spindle

Lubricate the spindle of the work-holder vice

Annually

Drive

Oil change

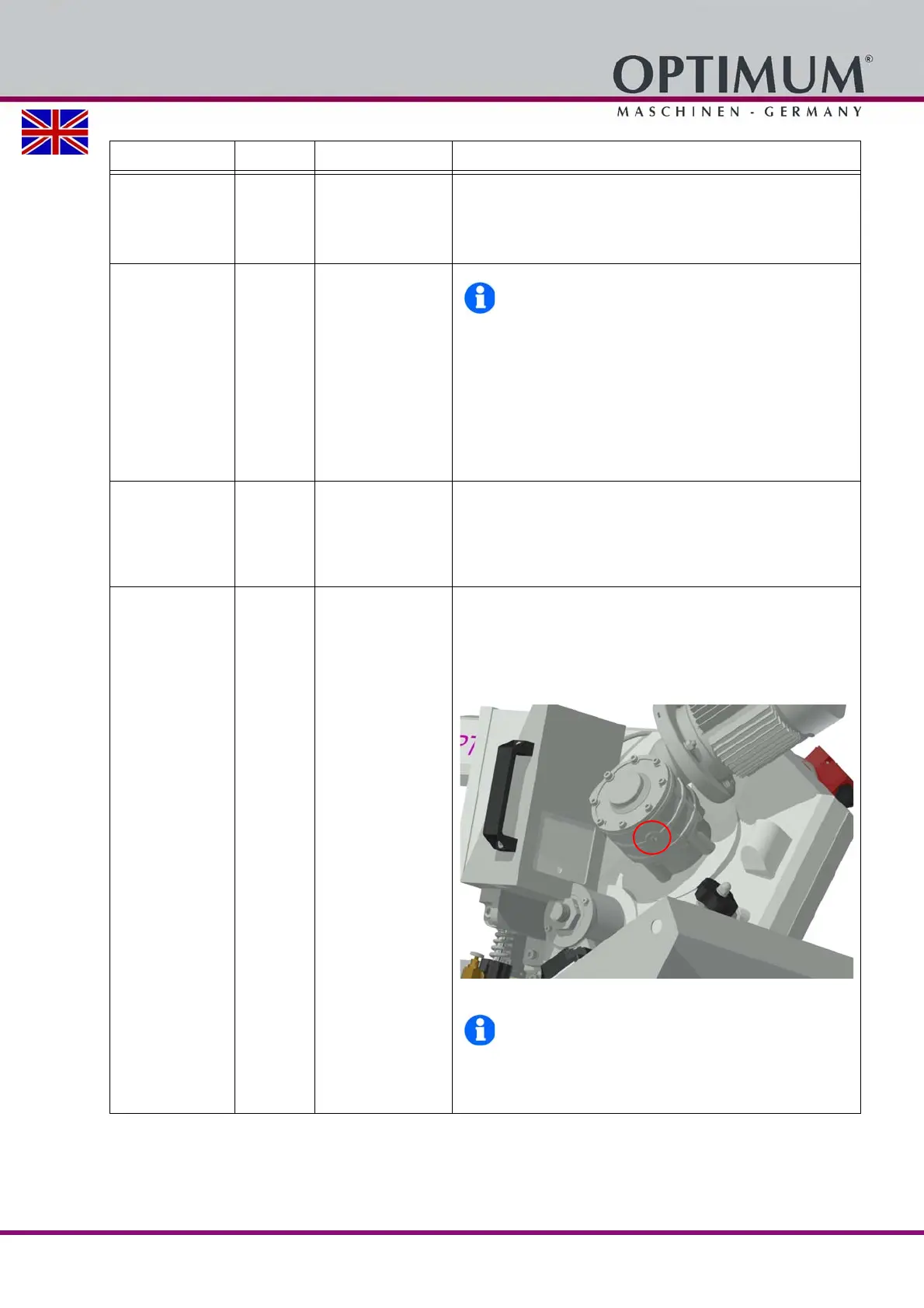

Unscrew the oil bleed screw at the bottom of the

helical gear. Use an adequate vessel with enough

capacity to collect the oil.

Open the filler cap for a better ventilation.

Use viscous gear oil, e.g. Mobil 629

Img.5-5: Helical gear

INFORMATION

Have the metal band saw run for a few minutes

before starting the oil change. The oil warms up and

flows more easily through the outlet.

Interval Where? What? How?

Loading...

Loading...