OPTIMUM

MASCHINEN - GERMANY

Maintenance

Version 1.1.5 dated 2015-08-31 Page 41Original operating instructions

BF30Vario GB

As required

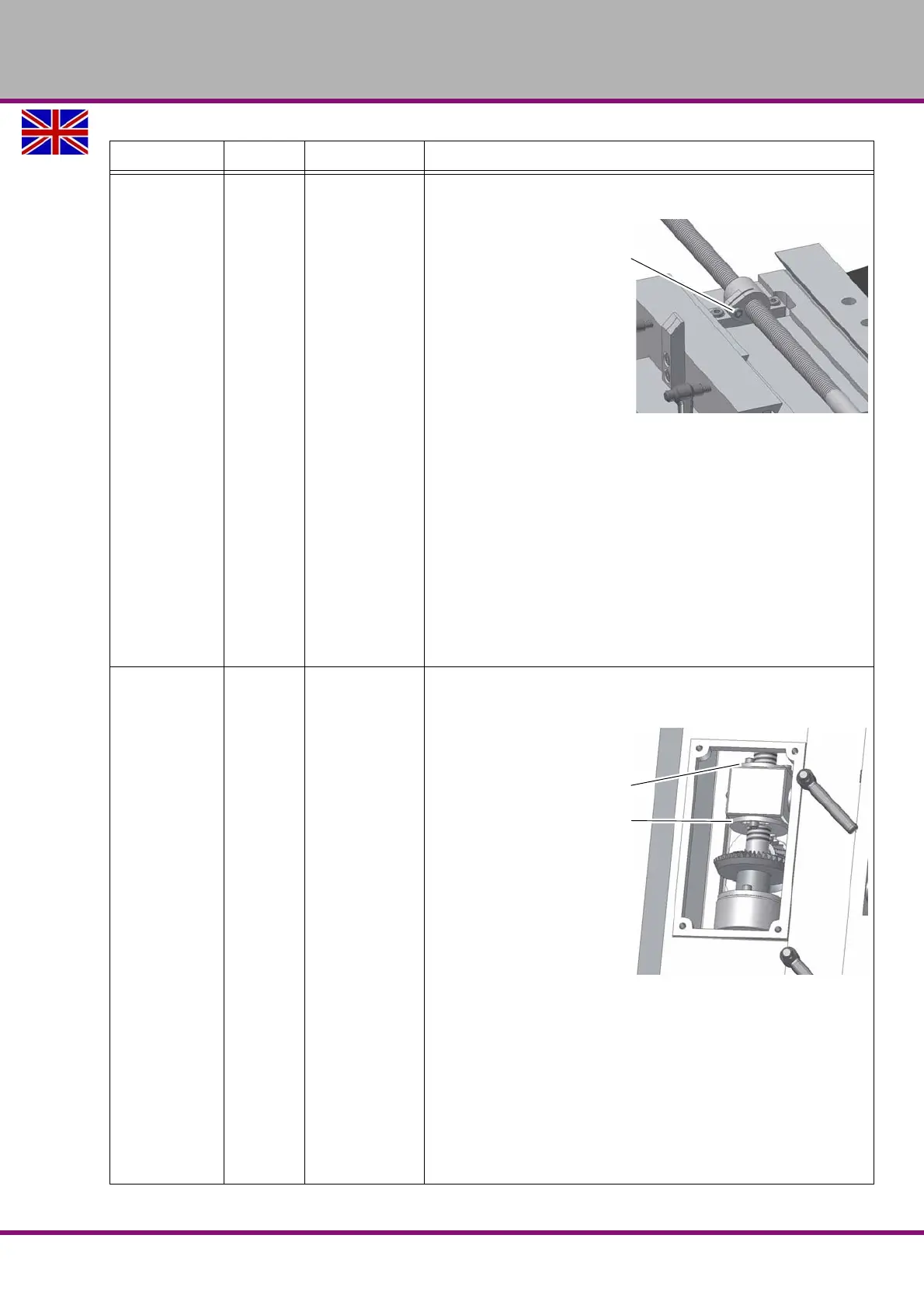

Spindle nut cross table

Readjusting

An extended clearance in the spindles of the cross table can

be reduced by readjusting the spindle nuts.

Img.5-5: Spindle nut X - axis (milling table faded

out)

The spindle nuts are readjusted by reducing the thread flanks

of the spindle nut by means of a regulating screw. Due to the

readjustment it is necessary to check if a smooth movement

over the whole travel is still given, otherwise the wear is con-

siderably increased due to the friction between the spindle nut

and the spindle.

The regulating screw of the spindle nut of the Y axis is acces-

sible from the rear side, the regulating screw of the spindle nut

of the x axis is accessible from the right or left side of the mill-

ing table.

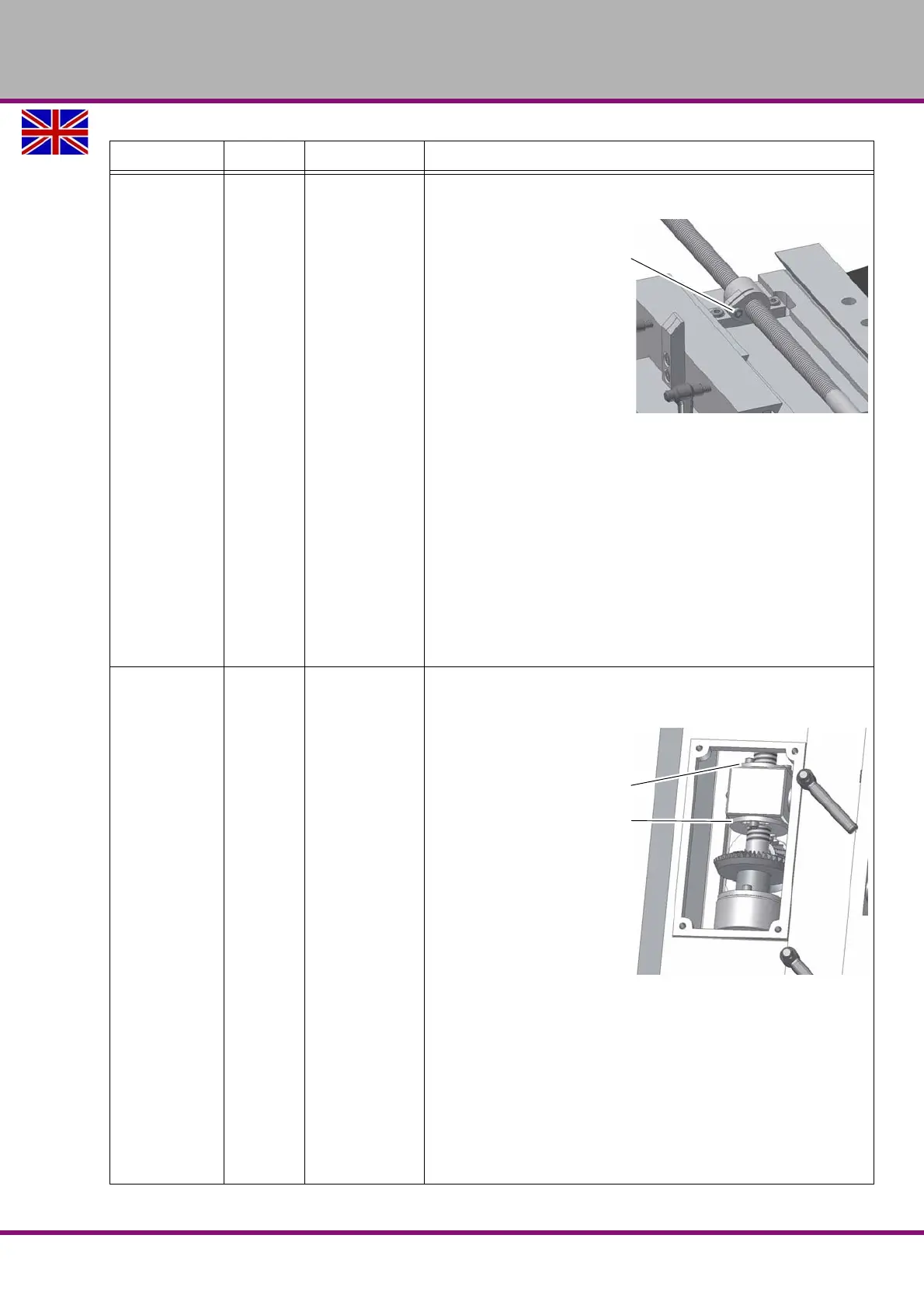

As required

Spindle nut Z- axis

Readjusting

An enlarged clearance in the spindle of the Z-axis can be per-

formed by reciprocal turning of the spindle nut.

Img.5-6: Spindle nuts Z-axis

Due to the readjustment it is necessary to check if a smooth

movement over the whole travel is still given, otherwise the

wear is considerably increased due to the friction between the

spindle nut and the spindle.

Turn the crank of the drilling-milling head as low as possi-

ble.

Firmly clamp the clamping lever left and right.

Remove the service cover from the column.

Interval Where? What? How?

Spindle nut adjusting screw

Spindle nut firm at the top

Spindle nut turnable at the bot-

tom

Loading...

Loading...