Installation

−

8

−

3 Installation

This chapter explains the installation location and installation methods.

3.1 Location for installation

The motor and speed controller described in this manual have been designed and manufactured to be incorporated in general

industrial equipment. Install them in a well-ventilated location that provides easy access for inspection.

•

Inside an enclosure that is installed indoors

•

Operating ambient temperature

Motor: The operating ambient temperature varies

depending on the AC input voltage of the motor.

100 VAC and 200 VAC types:

‒10 to +50

°

C [+14 to +122

°

F] (non-freezing)

110/115 VAC and 220/230 VAC types:

‒10 to +40

°

C [+14 to +104

°

F] (non-freezing)

Speed controller: 0 to +50

°

C [+32 to +122

°

F] (non-freezing)

•

Operating ambient humidity 85% or less (non-condensing)

•

Area that is free of explosive atmosphere or toxic gas

(such as sulfuric gas) or liquid

•

Area not stored combustible materials

•

Area not exposed to direct sun

•

Area free of excessive amount of dust, iron particles or the

like

•

Area not subject to splashing water (rain, water droplets),

oil (oil droplets) or other liquids

•

Area free of excessive salt

•

Area not subject to continuous vibration or excessive shocks

•

Area free of excessive electromagnetic noise (from welders,

power machinery, etc.)

•

Area free of radioactive materials, magnetic elds or vacuum

•

Altitude Up to 1000 m (3300 ft.) above sea level

3.2 Installing the motor

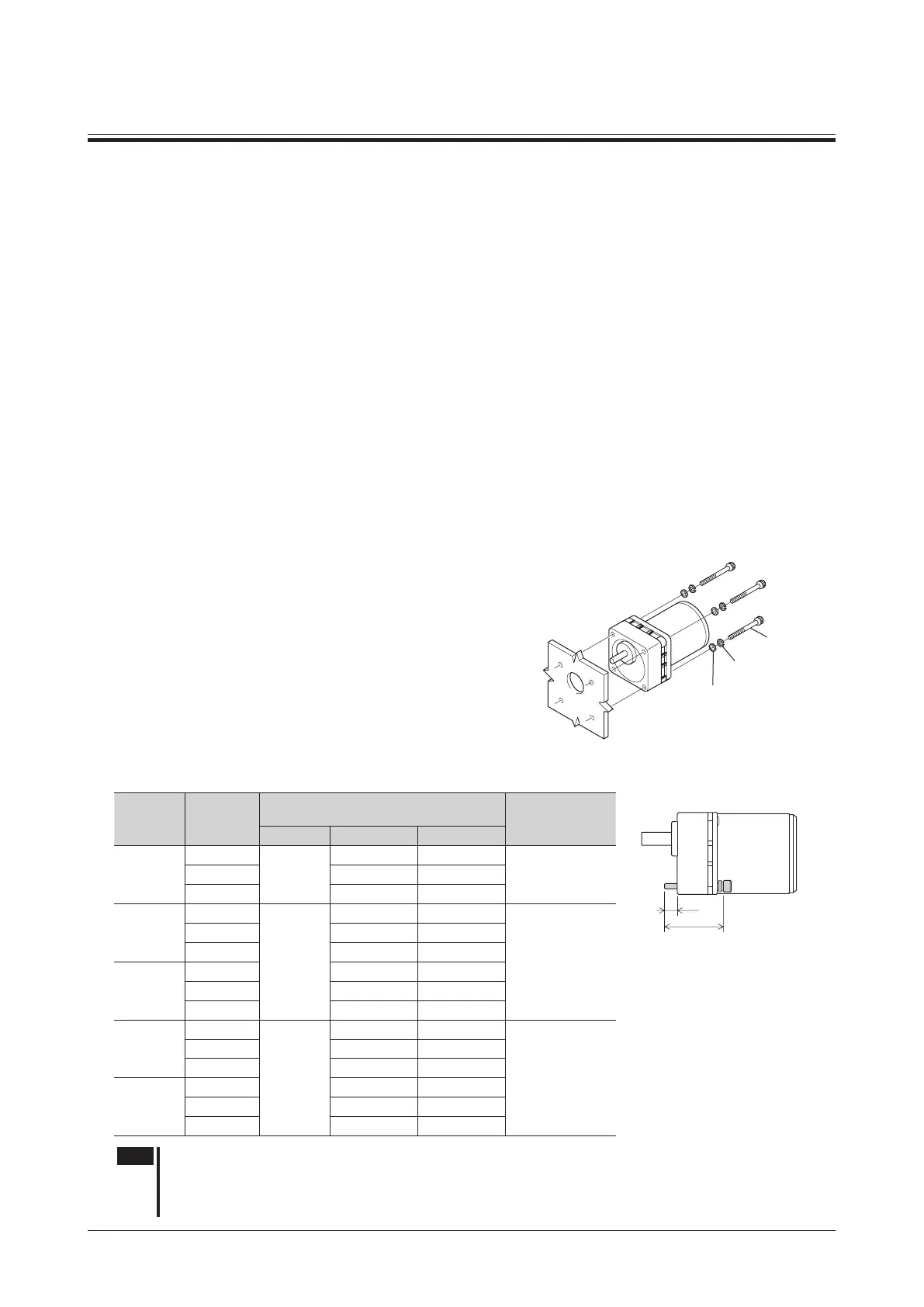

Installing the parallel shaft • combination type

Drill tapped holes in the mounting plate and secure the product with the

supplied hexagonal socket head screw set through four mounting holes.

Install it so that no gaps remain between the gearhead mounting surface

and mounting plate.

Motor

Gearhead

Mounting plate

Spring

washer

Washer

Hexagonal

socket head

screw

•

Supplied hexagonal socket head screw set

(Hexagonal socket head screws, washers, spring washers 4 pieces each)

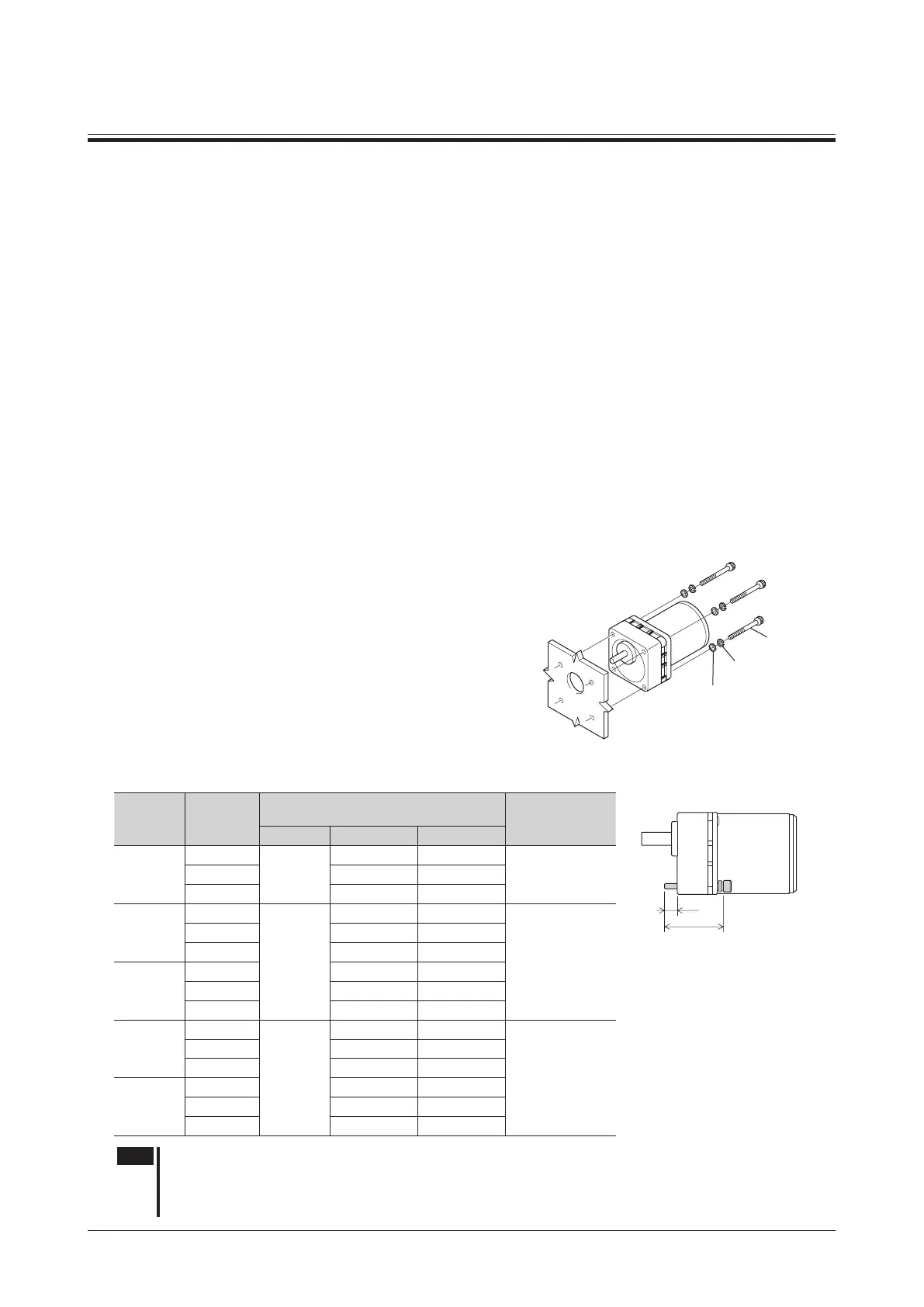

Gearhead

model

Gear ratio

Hexagonal socket head screw

(Material: Stainless steel)

Tightening torque

[N·m (lb-in)]

L2

L1

Screw size L1 [mm (in.)] L2 [mm (in.)]

2GV

o

B

5 to 25

M4

50 (1.97) 7 (0.28)

1.4 (12)30 to 120 55 (2.17) 8 (0.31)

150 to 360 60 (2.36) 8 (0.31)

3GV

o

B

5 to 25

M6

60 (2.36) 12 (0.47)

5.0 (44)

30 to 120 65 (2.56) 12 (0.47)

150 to 360 70 (2.76) 12 (0.47)

4GV

o

B

5 to 25 60 (2.36) 9 (0.35)

30 to 120 65 (2.56) 9 (0.35)

150 to 360 70 (2.76) 9 (0.35)

5GV

o

B

5GVH

o

B

5 to 18

M8

70 (2.76) 14 (0.55)

12.0 (106)

25 to 100 85 (3.35) 16 (0.63)

120 to 300 90 (3.54) 15 (0.59)

5GVR

o

B

5 to 15 70 (2.76) 14 (0.55)

18 to 36 85 (3.35) 16 (0.63)

50 to 180 95 (3.74) 14 (0.55)

Note

On rare occasions, a small amount of grease may ooze out from the gearhead. If there is a concern over

possible environmental damage resulting from the leakage of grease, provide an oil tray or similar oil

catching mechanism in order not to cause a secondary damage.

Oil leakage may lead to problems in the customer’s equipment or products.

Loading...

Loading...