(10)After

remounting

the

above, adjust

the

radial

alignment

according

to

the

procedure

in

section 9.6, adjust

the

track

00

sensor according

to

the

procedure in section 9.9.

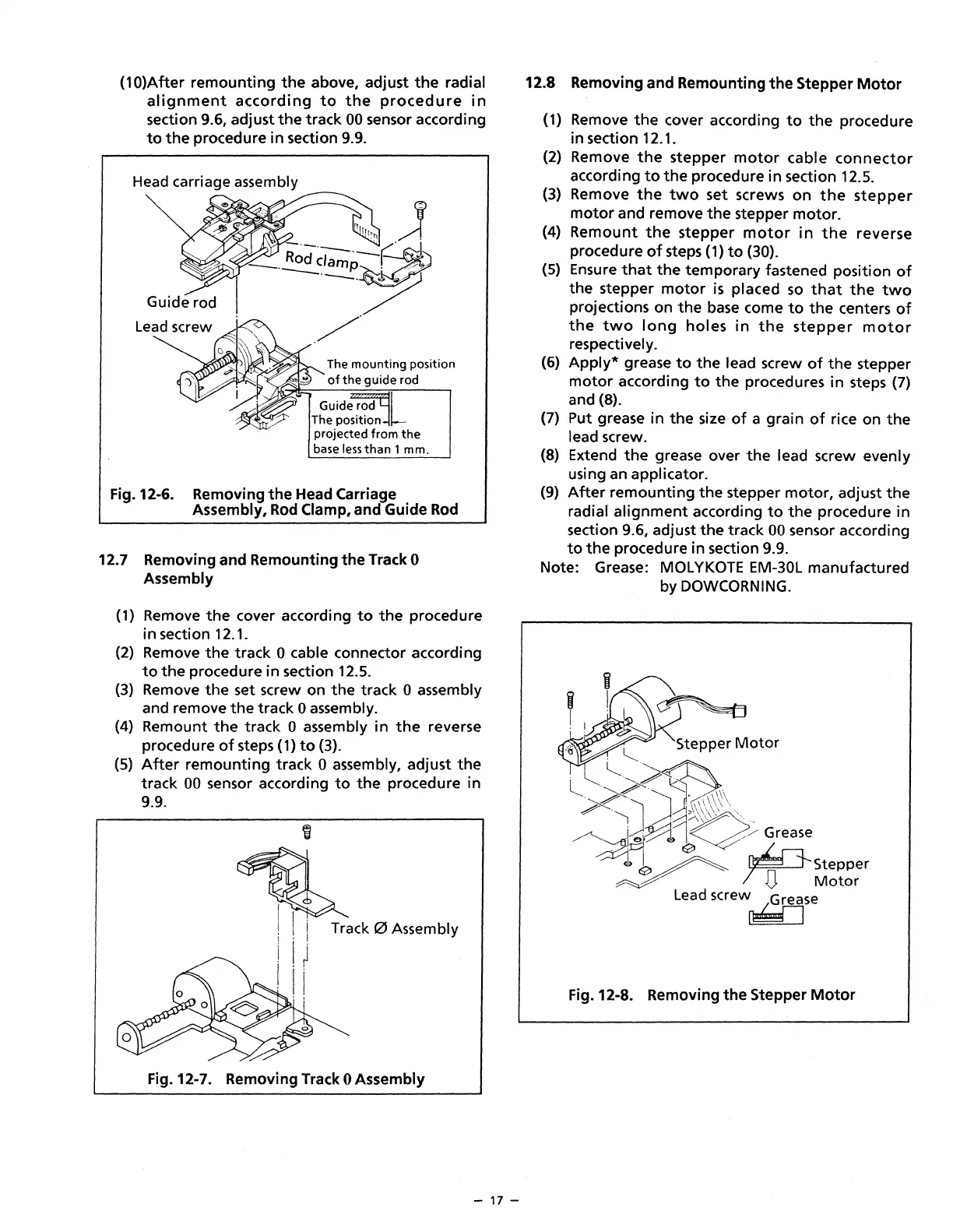

Head carriage assembly

Fig.12-6.

The mounting position

of

the guide rod

Guide rod L

The position

projected from

the

baselessthan 1 mm.

Removing

the

Head Carriage

Assembly,

Rod

Clamp, and Guide

Rod

12.7 Removing and Remounting

the

Track 0

Assembly

(1) Remove

the

cover according

to

the

procedure

in section 12.1.

(2) Remove

the

track 0 cable connector according

to

the

procedure in section 12.5.

(3) Remove

the

set screw on

the

track 0 assembly

and remove

the

track 0 assembly.

(4) Remount

the

track 0 assembly in

the

reverse

procedure

of

steps (1)

to

(3).

(5)

After

remounting

track 0 assembly, adjust

the

track

00

sensor according

to

the

procedure in

9.9.

;

~

I [ i Track 0 Assembly

I ' I

I I j

I

..

.

11

Fig. 12-7. Removing Track 0 Assembly

-

17

-

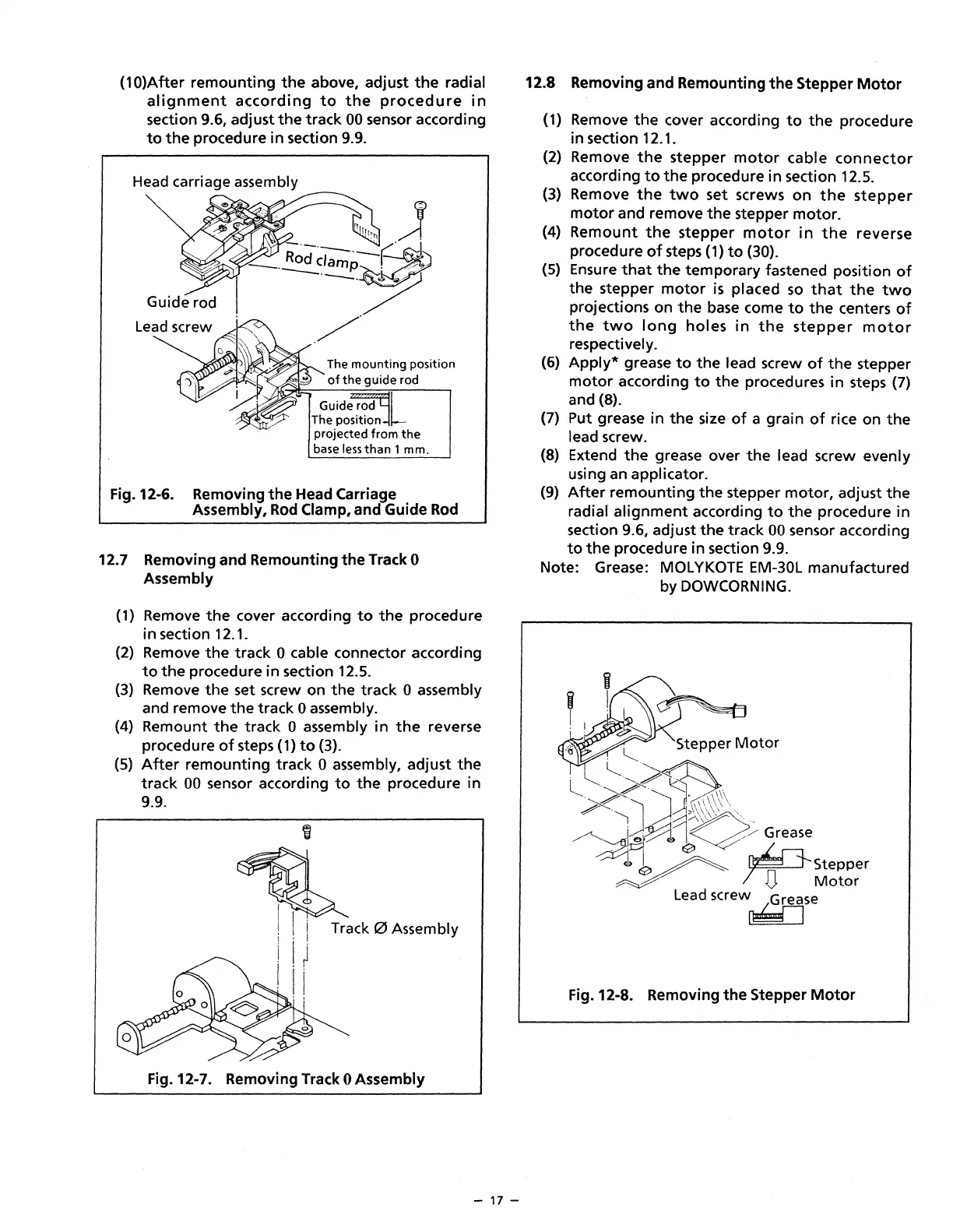

12.8 Removing and Remounting

the

Stepper

Motor

(1) Remove

the

cover according

to

the

procedure

in section 12.1.

(2) Remove

the

stepper

motor

cable

connector

according

to

the

procedure in section 12.5.

(3) Remove

the

two

set screws

on

the

stepper

motor

and remove

the

stepper

motor.

(4)

Remount

the

stepper

motor

in

the

reverse

procedure

of

steps (1)

to

{30).

(5) Ensure

that

the

temporary fastened position

of

the

stepper

motor

is

placed

so

that

the

two

projections on

the

base

come

to

the

centers

of

the

two

long

holes

in

the

stepper

motor

respectively.

(6)

Apply*

grease

to

the

lead screw

of

the

stepper

motor

according

to

the

procedures in steps (7)

and (8).

(7) Put grease

in

the

size

of

a grain

of

rice on

the

lead screw.

(8) Extend

the

grease over

the

lead screw evenly

using an applicator.

(9)

After

remounting

the

stepper

motor,

adjust

the

radial

alignment

according

to

the

procedure in

section 9.6, adjust

the

track

00

sensor according

to

the

procedure in section 9.9.

Note: Grease: MOL

YKOTE

EM-30L manufactured

by DOWCORNING.

Stepper

Motor

Fig. 12-8. Removing

the

Stepper

Motor

Loading...

Loading...