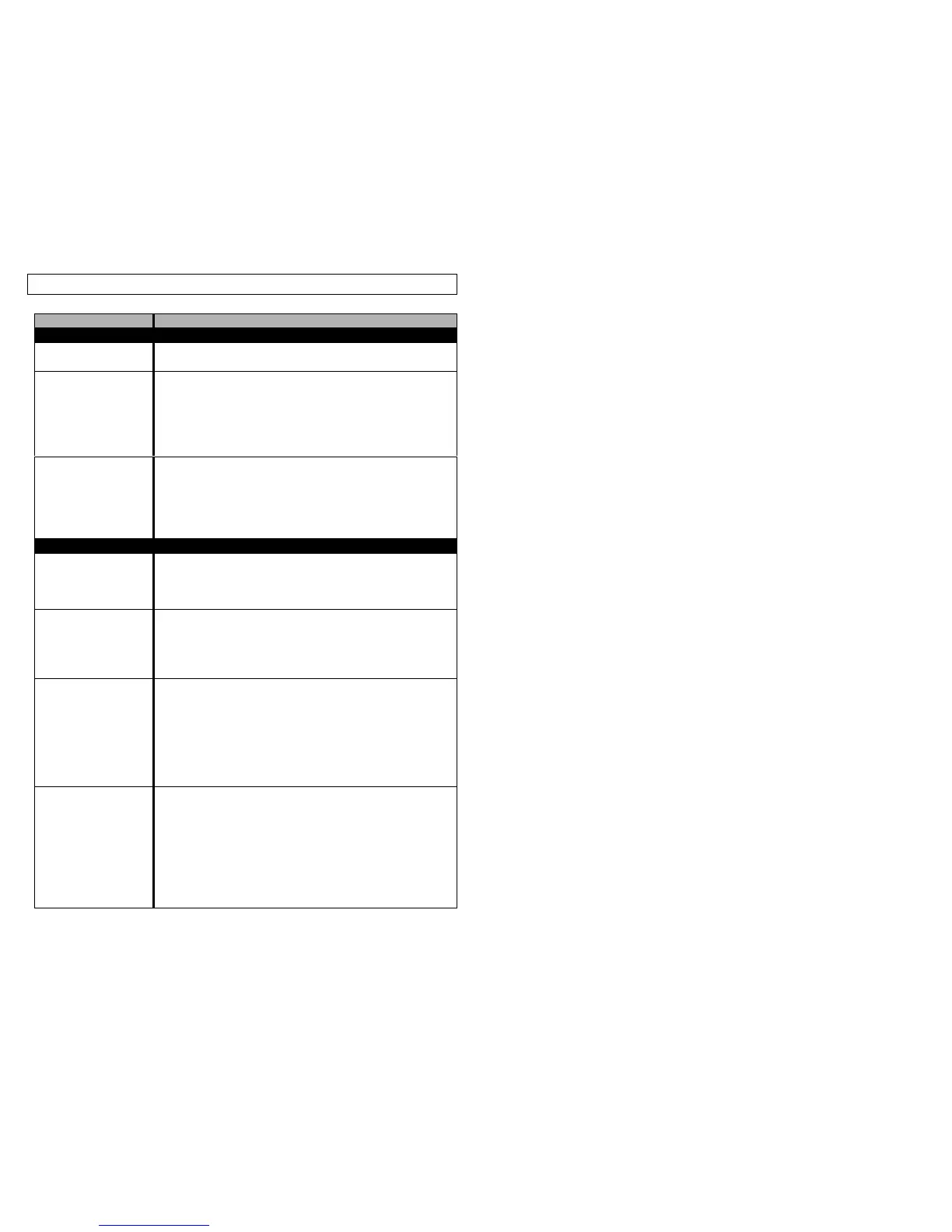

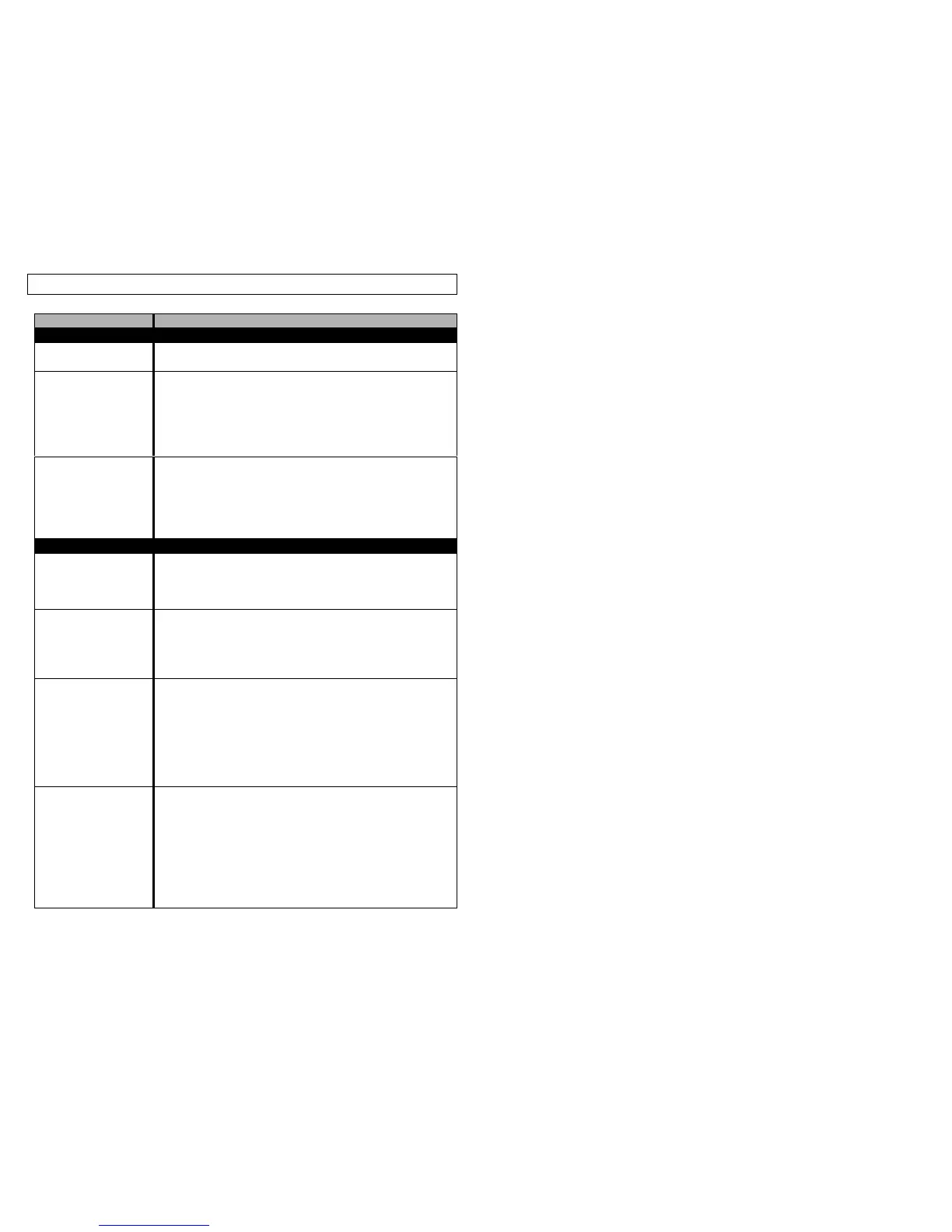

TROUBLESHOOTING

40

SYMPTOM ACTION

LABELS

Labels not

registering

• Make sure that label mandrel is firmly seated in

socket

• Width guide loose. Make sure the width guide is

properly placed and fixed in place. Per specific

label.

• Printer not reset for new label format. Turn printer

OFF, then ON again. Printer will re-calibrate for

new label.

Die-cut labels

continue to feed

without

“calibrating”.

• Label sensor is dirty or obstructed. Clean sensor

with soft-stemmed swab and isopropyl alcohol or

compressed air.

• Printer is set in “no notches” mode. Change

setting to “notches” mode in label software.

BAR CODES

Character does not

display on screen

when key is

depressed.

• Key is stuck. Make sure no keys are stuck in the

depressed position.

Poor edge

definition (bar

codes and

alphanumerics).

• Print speed is too high. Reduce print speed.

• Ribbon and media are incompatible. Test

alternative ribbon or media.

Bar codes

smearing (bar code

edges “bleeding” or

“feathering”.

• Print head energy setting is too high. Reduce

energy setting until bar edges are clean.

• Print speed is too high. Reduce print speed.

• Rotated (“ladder” style) bar code is being used.

Change label design to include only normal

(“picket fence” style) bar codes.

Bars in bar codes

are too wide or too

narrow resulting in

a poor scan grade.

• Print speed is too high. Reduce print speed.

• Print head energy setting it too high/too low.

Adjust to optimize average bar growth (visually or

with verifier).

Overburn (too much ribbon transfer). Reduce print

head energy setting or use a ribbon with lower

sensitivity (refers to ribbons requiring more energy).

Loading...

Loading...