Mounting

192-550003N10 ETH ATEX December 2019 27

For all mounting options the following applies:

Joint area must be dry and free of grease

We recommend to secure the screws with a liquid bolt retaining compound (e.g.

Loctite 242)

With mounting option F, H and J, do not mount the cylinder horizontally on one

side as in this case the bolted connections are improperly high burdened due to

pitching torques and cross forces. In this case always support the cylinder!

With ETH032-080 the mounting thread F* on the underside of the cylinder can be

used as support.

With ETH100&125 the transporting thread (see page 18) can be used as support. For

this a screw M12x1.25, quality 8.8 must be used. Furthermore, a minimum screw-in

depth of 15 mm must be adhered to. Tighten screw with tightening torque 30 Nm.

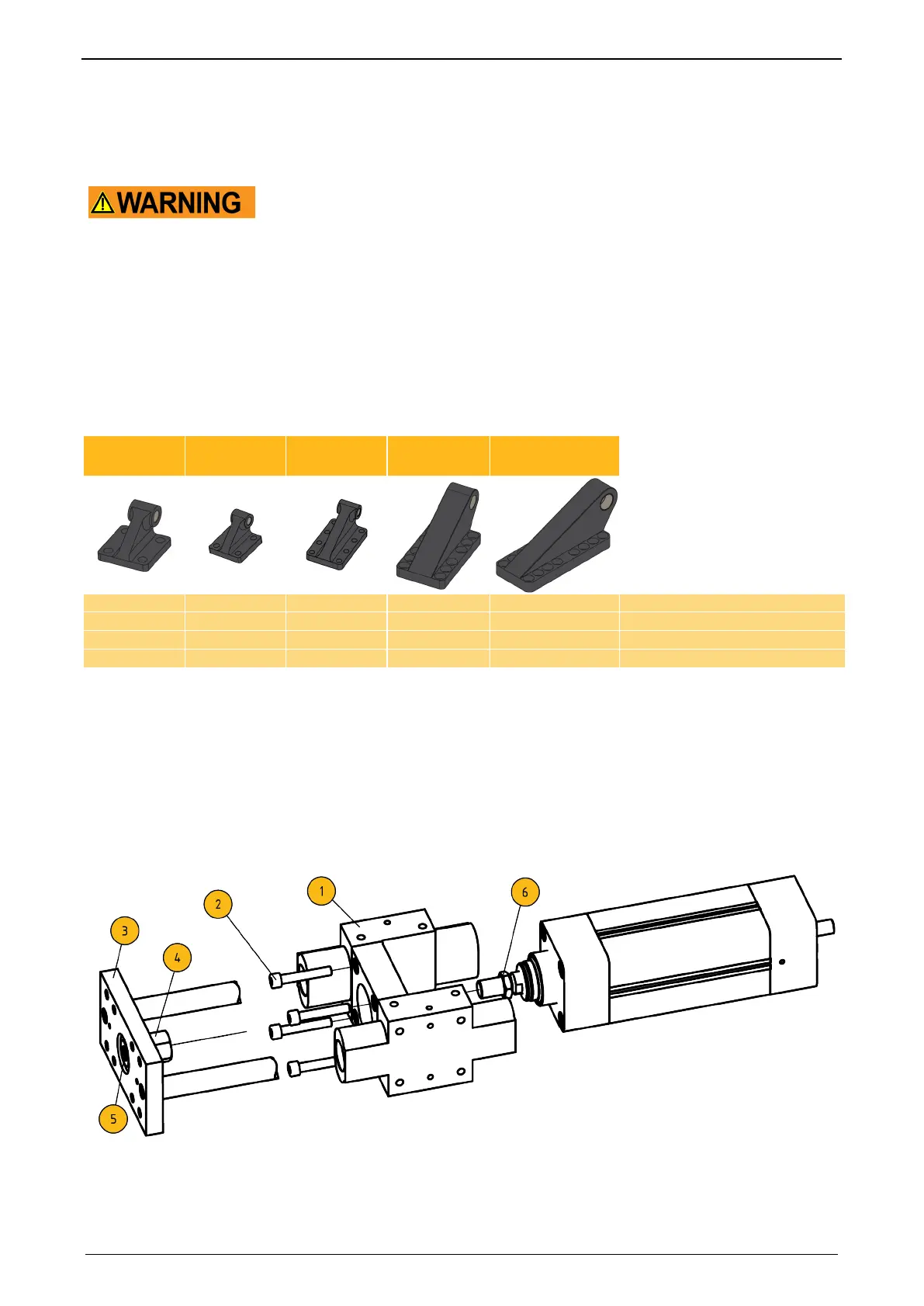

2.1.2.3 Accessory mounting - bearing block

Tightening torques for the bearing block to be provided by the customer.

ETH032 ETH050 ETH080 ETH100 ETH125

Screw tightening torque (1) [Nm]

Minimum screw-in depth (2) [mm]

(1) torque controlled tightening

(2) when screwing into S235 JRG1 grade steel

Boundary conditions:

Provide suitable washer under the screw head

Joint area must be dry and free of grease

We recommend to secure the screws with a liquid bolt retaining compound (e.g.

Loctite 242)

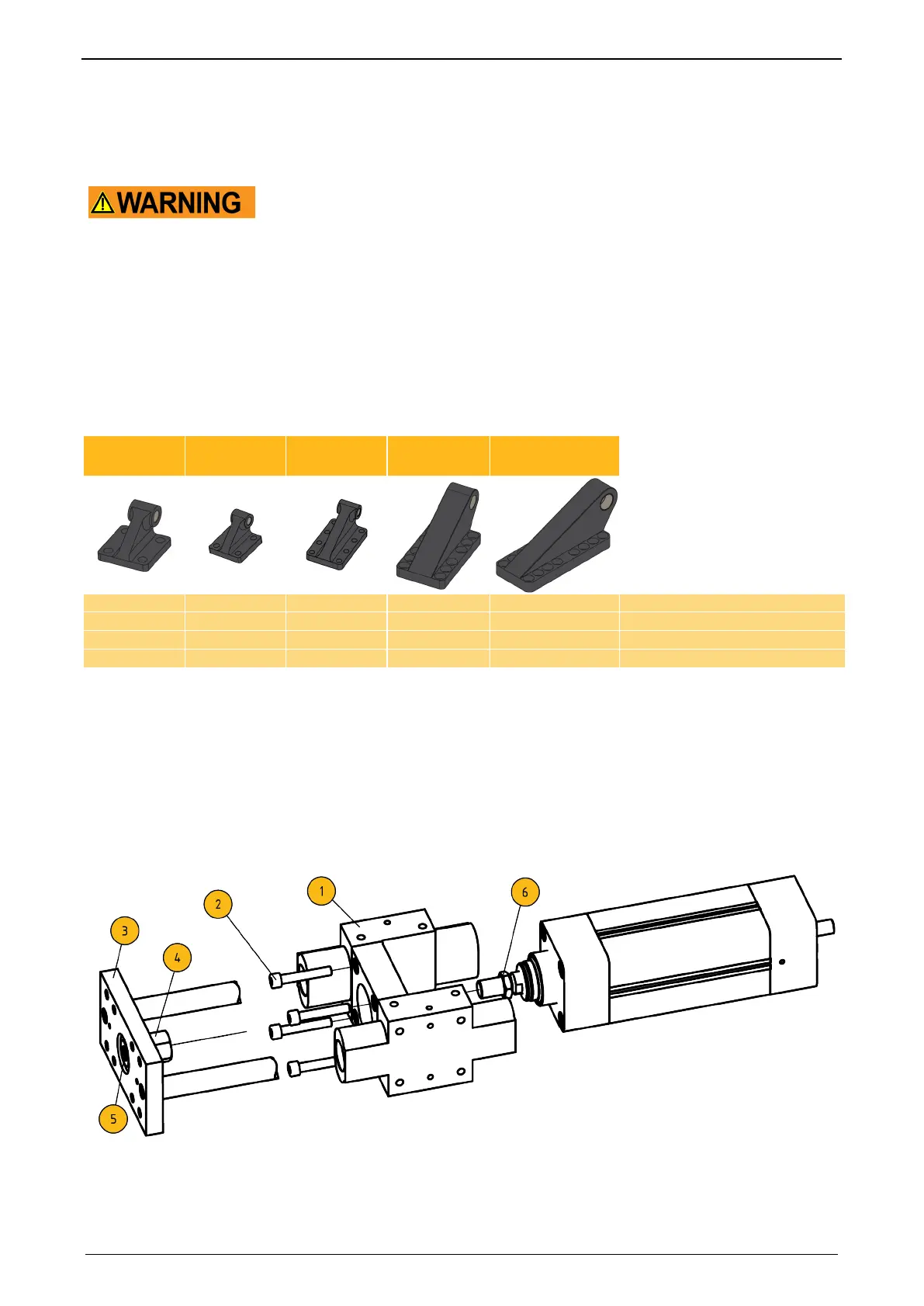

2.1.2.4 Mounting the rod guide (option R)

The rod guide is only available for fram sizes ETH032 ... ETH080!

Figure 8: Mounting the rod guide

Place the cylinder on a suitable installation surface.

For the following steps, the piston rod of the cylinder must be retracted.

Unwrap the rod guide and remove the transportation lock between the rod guide

module ((see Figure 8 Pos.1) and the front plate (see Figure 8 Pos. 3).

Loading...

Loading...