Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2708-02/SVC/EN | July 2019

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

41

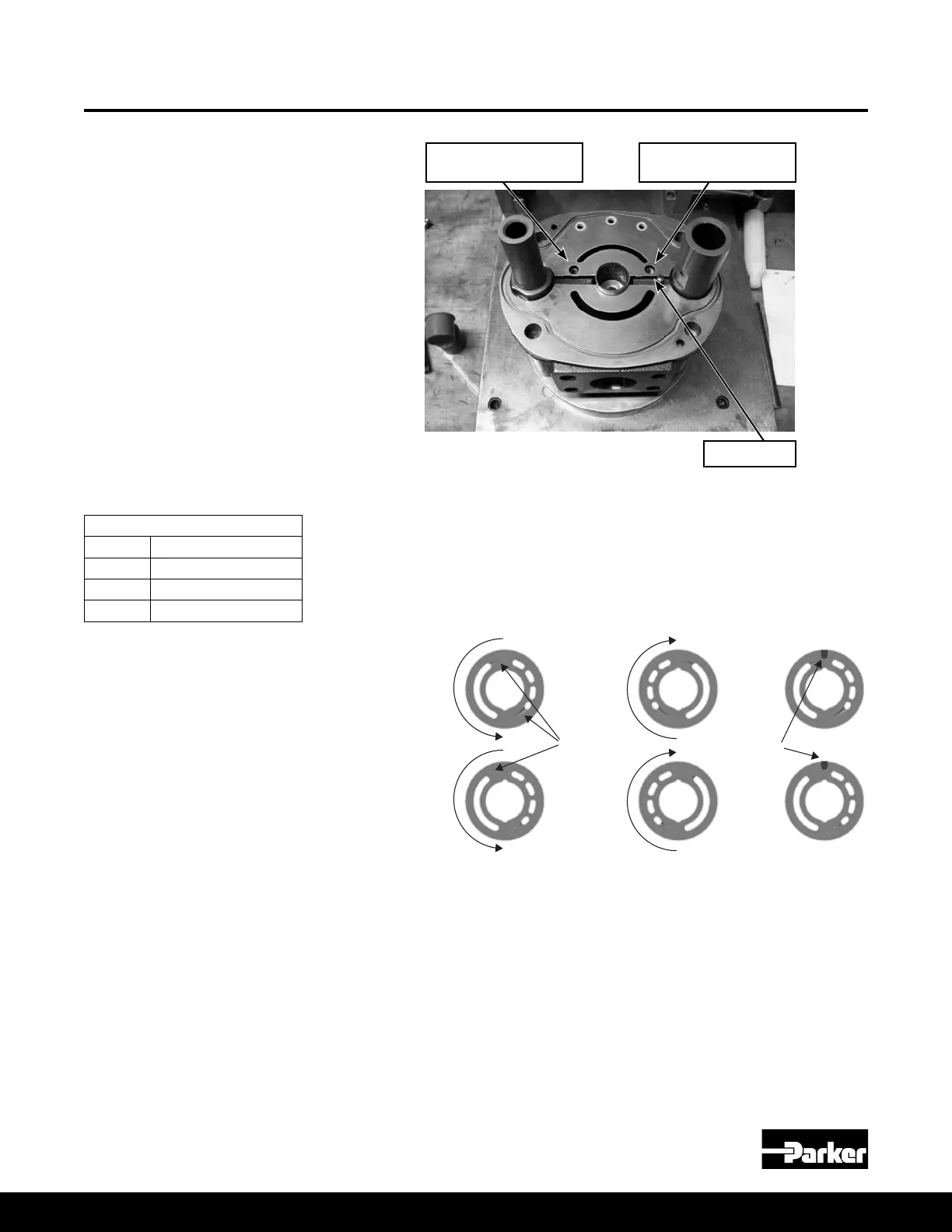

Note Slot Length

and Quantity

Industrial Port Plates

Mobile Port Plates

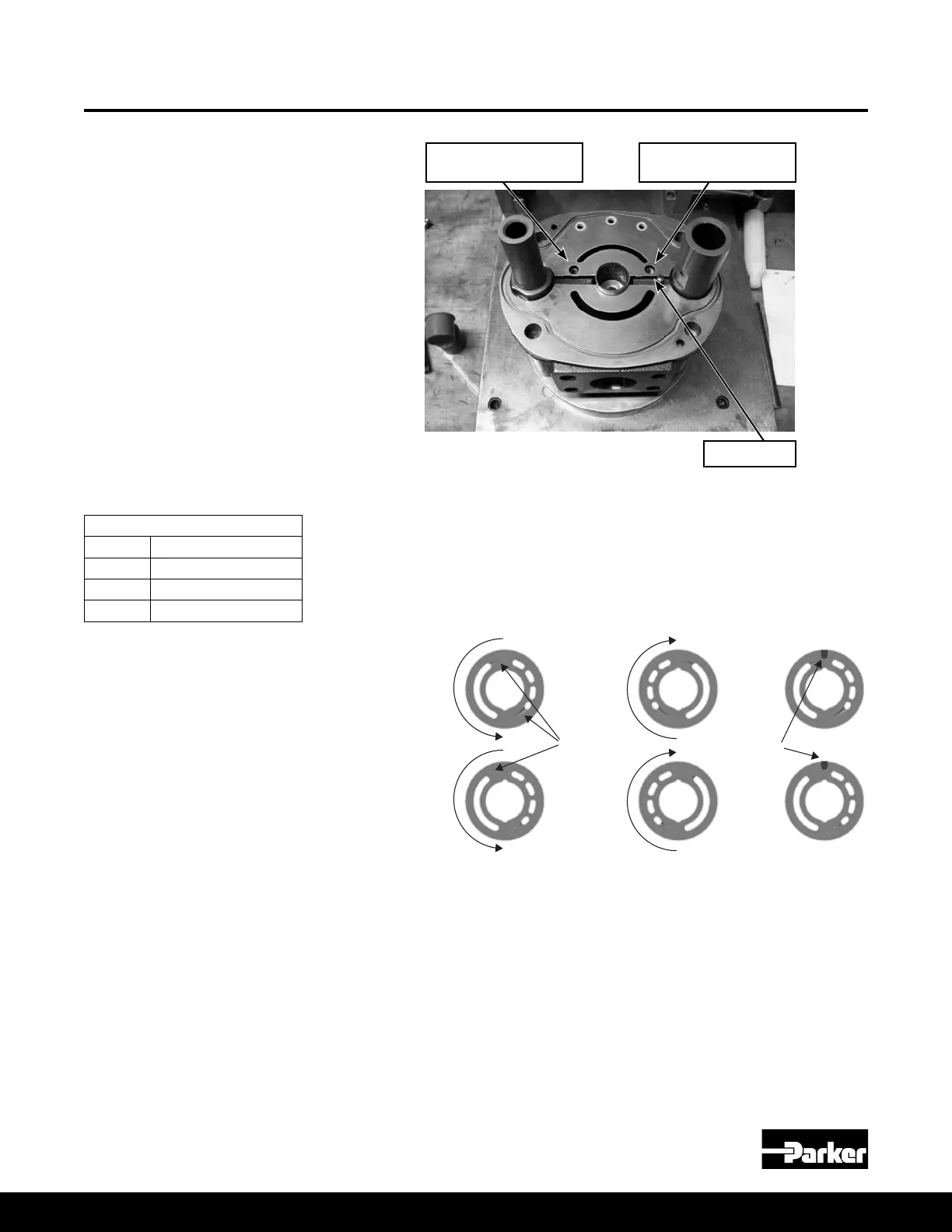

CCW Port Plates CW Port Plates Back Surface

Locating Pin Slot

Figure 7

Table 3

Pump Housing bolt torque

018 52 ft lbWs (70 Nm)

028 52 ft lbs (70 Nm)

045 63 ft lbs (85 Nm)

13. Install the port block bushing (#18) into the port block face using tool T5.

14. Apply a light layer of petroleum jelly to the back surface of the port plate (#9).

Install it on the port block (#3), lining up the slot on the port plate with the port

plate locating pin (#7). See Figure 7.

15. Install the large O-ring (#4) into the groove on the port block (#3). Install the

three Teon O-rings (#8) on the pressure communication ports on the port

block.

16. Install the control ow housing set screw (#34) into the proper passage. For

proper location, see Figure 12 in the rotation change section.

17. Place the cam bearings (#31) in the cradle area of the housing. Apply two

drops of Loctite 243 (use sparingly) to the cam bearing screw (#30) threads

and install the screws to hold the cam bearings in place. Torque the screws

per the torque table on page 7.

Figure 6 - Port Block Assembly with Ripple Chamber

Pump Assembly Procedures

(Continued)

018, 028, 045 Assembly Procedures

Dowel Pin

Ripple chamber set screw

location - CW

Ripple chamber set screw

location - CCW

Loading...

Loading...