TIMER OPERATION

Setting the Time of Day

NOTE: Set Time of Day on the Lead Unit (#1) and the rest of

the units in the system will update the Time of Day

within 10 seconds.

1. Press and hold the Up or Down button for 2 seconds.

2. Press the Shift button to select the digit you want to modify.

3. Press the Up or Down buttons to adjust the valve.

4. Press the Extra Cycle button to return to the normal display

screen, or wait for a 5 second timeout.

NOTE: The "D" button (Diagnostic) can be pressed to exit

without saving.

Manually Initiating a Regeneration

1. When timer is In Service or Stand By, press the Extra Cycle

button for 5 seconds on the main screen.

2. The timer advances to Regeneration Cycle Step #1, and

begins programmed time count down.

3. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #2 (if active).

4. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #3 (if active).

5. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #4 (if active).

6. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #5 (if active).

7. Press the Extra Cycle button once more to advance the

valve back to In Service.

NOTE: A manually initiated or queued regeneration can

be cleared by pressing the Extra Cycle button for

less than 5 seconds. A system queued regeneration

can only be cleared by stepping through a manual

regeneration. If regeneration occurs for any reason

prior to the delayed regeneration time, the manual

regeneration request shall be cleared. Pressing

the Extra Cycle button while in regeneration will

cause the upper drive to advance to the next step

immediately.

Timer Operation During Regeneration

In the Regeneration Cycle step display, the timer shows

the current regeneration cycle number the valve is in, or

has reached, and the time remaining in that step. Once all

regeneration steps are complete the timer returns to In Service

and resumes normal operation.

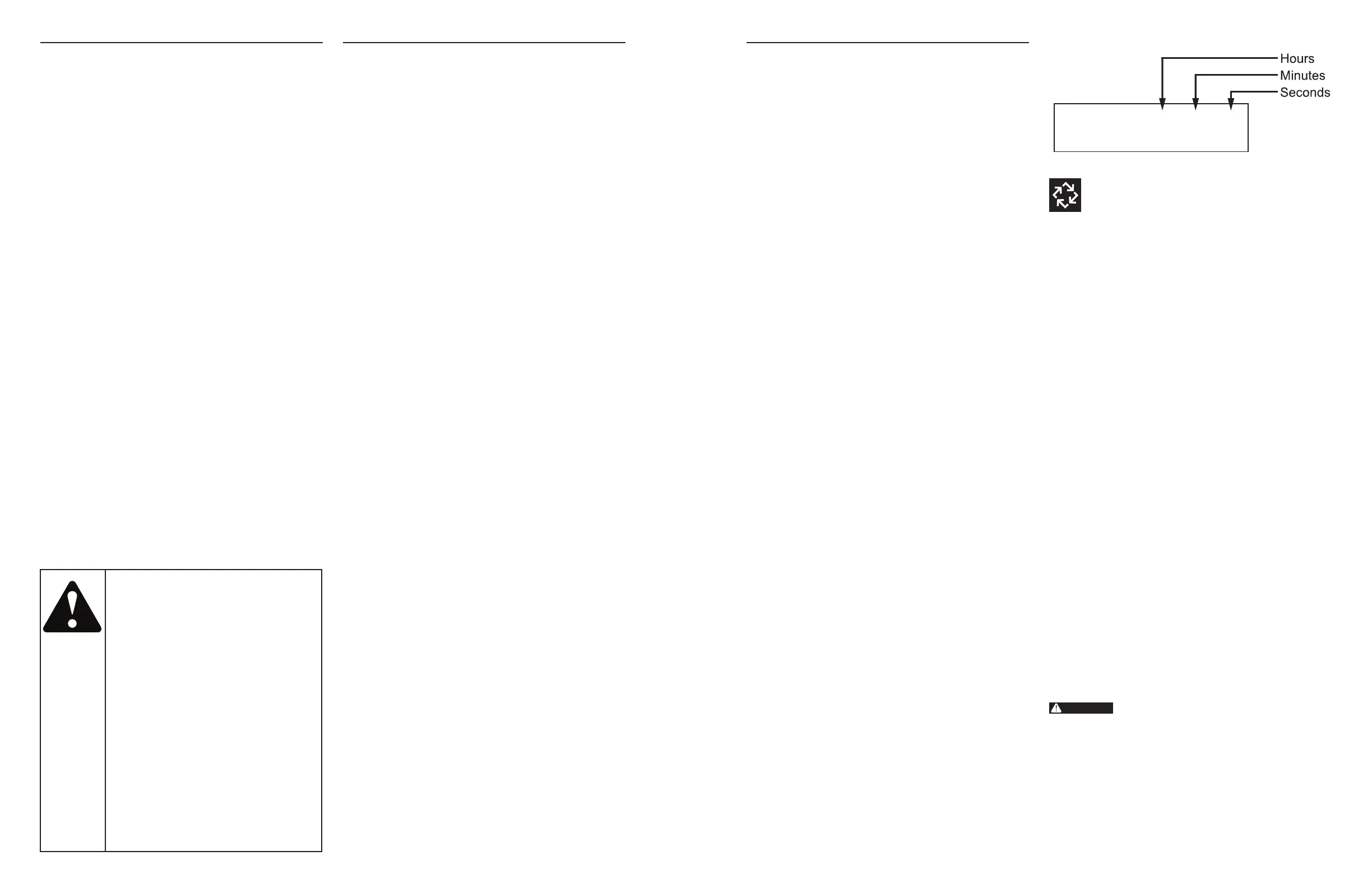

CYCLE 1 00:00:00

BACK WASH

Example: 12 minutes remaining in Cycle 1 (Backwash)

Press the Extra Cycle button during a system

queued Regeneration Cycle to immediately

advance the valve to the next cycle step position

and resume normal step timing.

Flow Meter Equipped Timer

As treated water is used, the Volume Remaining display counts

down from the calculated system capacity to zero. When zero

is reached a Regeneration Cycle begins if no other units are in

regeneration.

Timer Operation During Programming

The timer enters the Program Mode in Standby or Service

Mode as long as it is not in regeneration. While in the Program

Mode the timer continues to operate normally monitoring

water usage. Timer programming is stored in memory

permanently.

Timer Operation During A Power Failure

All program settings are stored in permanent memory. Current

valve position, cycle step time elapsed, and time of day are all

stored during a power failure, and will be restored when power

is re-applied. Time is kept during a power failure, and time of

day is adjusted upon power up (as long as power is restored

within 12 hours).

NOTE: The time of day on the main display screen will flash

for 5 minutes when there has been a power outage.

The flashing of the time of day can be stopped by

pressing any button on the display.

Remote Lockout

The timer does not allow the unit/system to go into

Regeneration until the Regeneration Lockout Input signal to

the unit is cleared. This requires a contact closure to activate

the unit. The recommended gauge wire is 20 with a maximum

length of 500 feet. See P4 remote inputs in the wiring diagrams

in the service manual.

Regeneration Day Override Feature

If the Day Override option is turned on and the valve reaches

the set Regeneration Day Override value, the Regeneration

Cycle starts if no other unit is in Regeneration. If other units

are in regeneration, it is added to a regeneration queue. This

occurs regardless of the remaining volume available.

Transformer must be grounded and ground

wire must be terminated to the back plate

where grounding label is located before

installation.

IMPORTANT PLEASE READ:

• The information, specifications and illustrations in this manual

are based on the latest information available at the time of

printing. The manufacturer reserves the right to make changes

at any time without notice.

• This manual is intended as a guide for service of the controller

only. System installation requires information from a number of

suppliers not known at the time of manufacture. This product

should be installed by a plumbing professional.

• This unit is designed to be installed on potable water systems

only.

• This product must be installed in compliance with all state

and municipal plumbing and electrical codes. Permits may be

required at the time of installation.

• If daytime operating pressure exceeds 80 psi, nighttime

pressures may exceed pressure limits. A pressure reducing

valve must be installed.

• Do not install the unit where temperatures may drop below 32°F

(0°C) or above 110°F (43°C).

• Do not place the unit in direct sunlight. Black units will absorb

radiant heat increasing internal temperatures.

• Do not strike the controller or any of the components.

• Warranty of this product extends to manufacturing defects.

Misapplication of this product may result in failure to properly

condition water, or damage to product.

• A prefilter should be used on installations in which free solids

are present.

• Correct and constant voltage must be supplied to the controller

to maintain proper function.

TABLE OF CONTENTS

JOB SPECIFICATION SHEET .................................................... 2

TIMER OPERATION .................................................................. 3

SYSTEM DEFINITIONS ............................................................. 4

SYSTEM OPERATION IN SERVICE

(SYSTEM 14-DEMAND RECALL) .............................................. 5

FLOW IN A FOUR-UNIT SYTEM

(SYSTEM 14-DEMAND RECALL) .............................................. 6

TIMER DISPLAY FEATURES ..................................................... 6

TIMER DISPLAY - SCREEN EXAMPLES

(SYSTEM 4 THROUGH 6) .......................................................... 7

TRANSFORMER AND GROUND CONNECTIONS ..................... 7

NETWORK/COMMUNICATION CABLES AND CONNECTIONS 8

MASTER PROGRAMMING MODE FLOW CHART ...................... 8

USER PROGRAMMING MODE FLOW CHART ........................... 11

DIAGNOSTIC PROGRAMMING MODE FLOW CHART ............... 11

2750/2850/2900S UPPER & 2900S

LOWER POWERHEAD ASSEMBLY........................................... 13

3150/3900 UPPER & LOWER POWERHEAD ASSEMBLY ......... 15

METER ASSEMBLY PLASTIC ................................................... 17

1-INCH BRASS METER ASSEMBLY ......................................... 18

1-INCH STAINLESS STEEL METER ASSEMBLY ...................... 19

1-1/2 INCH BRASS METER ASSEMBLY ................................... 20

1-1/2 INCH STAINLESS STEEL METER ASSEMBLY ............... 21

2 INCH BRASS METER ASSEMBLY .......................................... 22

2 INCH STAINLESS STEEL METER ASSEMBLY ....................... 23

3 INCH BRASS METER ASSEMBLY .......................................... 24

3 INCH STAINLESS STEEL METER ASSEMBLY ....................... 25

SINGLE PISTON WIRING DIAGRAM ......................................... 26

DUAL PISTON WIRING DIAGRAM ............................................ 27

REMOTE TIMER WIRING DIAGRAM ......................................... 28

2750/2850 REMOTE TIMER WIRING DIAGRAM ....................... 29

2900 REMOTE TIMER WIRING DIAGRAM ................................ 30

3900 REMOTE TIMER WIRING DIAGRAM ................................ 31

3150 REMOTE METER WIRING DIAGRAM ............................... 32

TROUBLESHOOTING ................................................................ 33

JOB SPECIFICATION SHEET

Please Circle and/or Fill in the Appropriate Data for Future

Reference:

Programming Mode:

Feed Water Hardness: _________ Grains per Gallon or mg CaCO

3

/L

Regeneration Time: Delayed ______________AM/PM or Immediate

Regeneration Day Override: Off or Every __________________ Days

Master Programming:

System Type:

4 - Single Unit

5 - Parallel Unit

6 - Parallel Series Regen

7 - Twin Alternating

9 - Alternating

14 - Demand Recall

Valve Type: 2750 2850 2900s 3150 3900

System Size: 1 Valve 2 Valves 3 Valves 4 Valves

Valve Address: #1 #2 #3 #4

Regenerant Flow: Downflow or Upflow

Brine Draw First or Brine Fill First

Display Format: US Gallons or Liters

Unit Capacity: ________________________ Grains or grams CaCO

3

Capacity Safety Factor: Zero or ____________________________%

Trip Points (Gallons or M

3

):_____ Point 1 _____ Point 2 _____ Point 3

Trip Delays: _______ Delay 1 _______ Delay 2 _______ Delay 3

Regeneration Cycle Step #1: _ _ : _ _ : _ _

Regeneration Cycle Step #2: _ _ : _ _ : _ _

Regeneration Cycle Step #3: _ _ : _ _ : _ _

Regeneration Cycle Step #4: _ _ : _ _ : _ _

Regeneration Cycle Step #5: _ _ : _ _ : _ _

Timed Auxiliary Relay Output Window:

Off or Start Time _ _ : _ _ : _ _

End Time _ _ : _ _ : _ _

Chemical Pump Output Auxiliary Relay:

Off or Volume (Gallons or Liters) ______________________

Time _ _ : _ _ : _ _

Fleck Flow Meter Size:

Paddle: 1" 1.5" 2" 3"

Turbine: 1" 1.5"

Generic Flow Meter:

Maximum Flow Rate:

Add _ _ Gallons every _ _ Pulses

2 • Fleck 3200 NXT Fleck 3200 NXT • 3

Loading...

Loading...