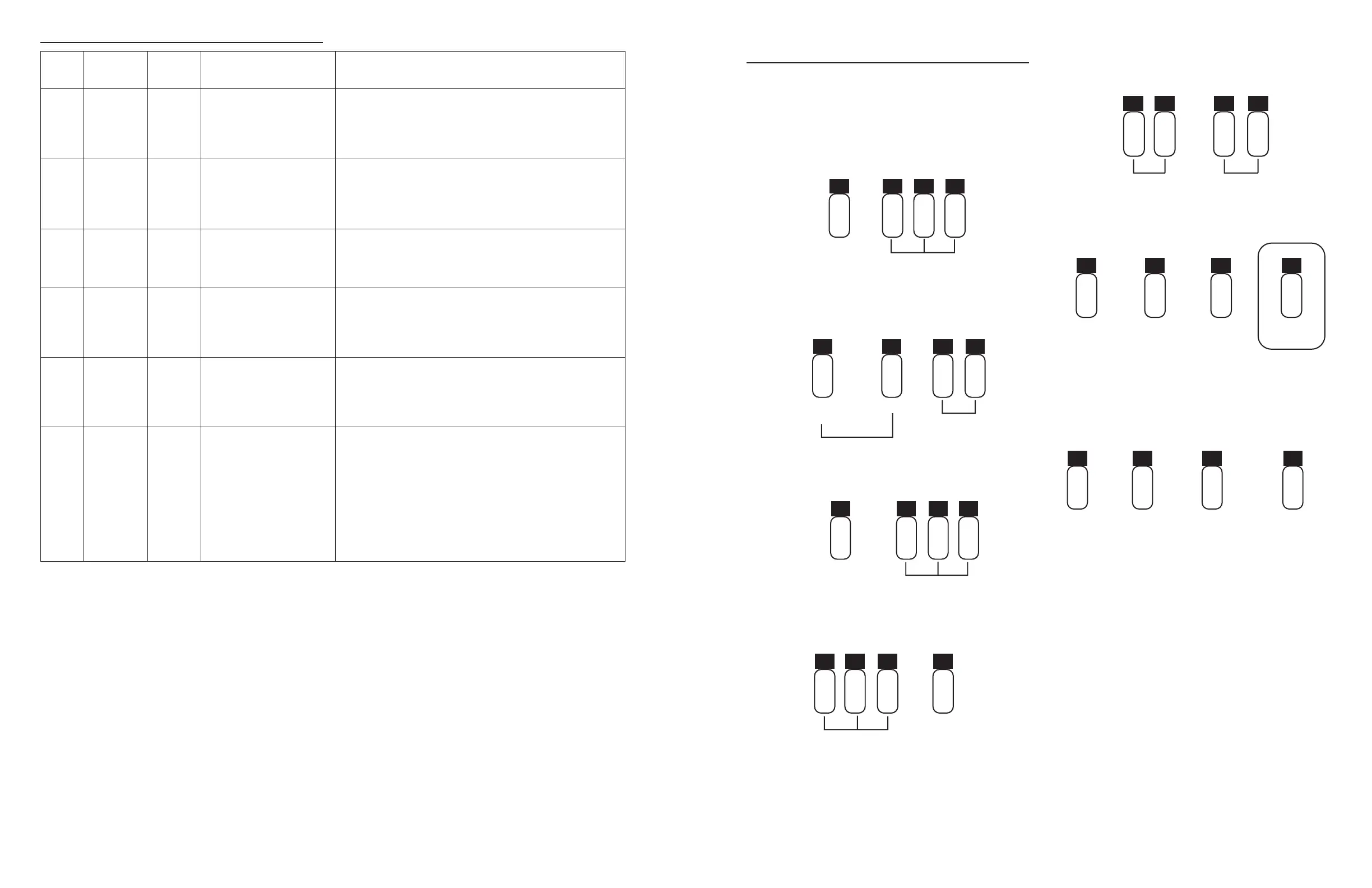

SYSTEM DEFINITIONS

System

Number

System

Description

# of

Tanks/

Controls

Type Operation Discussion

4 Single Unit 1 Time Clock: No Meter

Immediate: One Meter

Delayed: One Meter

Remote Signal Start: No Meter

Single tank configuration.

5 Interlocked 2, 3, or 4 Immediate: All Meters

Remote Signal Start: No Meter

All tanks in parallel supplying treated water. Each unit in the system

will have its own flow meter/sensor input. The control will delay the

start of Regeneration if another unit is already in Regeneration. Once

that unit has completed a Regeneration cycle, and has returned to

Service,the unit with longest regeneration queue time will begin

Regeneration. No more than one unit will be in Regeneration at a time.

6 Series

Regeneration

2, 3, or 4 Immediate: One Meter

Delayed: One Meter

Remote Signal Start: No Meter

All tanks in parallel supplying treated water. Only #1 control will

monitor flow meter/sensor input. When a regeneration is required

for the system, it will regenerate valve address #1 first, immediately

followed by #2, then #3, then #4 if installed. No more than one unit

will be in Regeneration at a time.

7 Twin

Alternating

2 Immediate: One Meter

Remote Signal Start: No Meter

One tank online supplying treated water, one tank in Standby. Only

#1 control will monitor its flow meter/sensor input. Regeneration of

a unit will begin after the other control has left Standby and returned

to Service. When the Regeneration cycle is complete, the regenerated

unit will enter Standby. Standby on each tank is controlled by the lower

drive output terminals on the NXT circuit board.

9 Multiple Tank

Alternating

2, 3, or 4 Immediate: All Meters

Remote Signal Start: No Meter

One, two, or three tanks online supplying treated water, one tank in

Standby. Meter/sensor input is required on each tank. Regeneration of

a unit will begin after the other control has left Standby and returned

to Service. When the Regeneration cycle is complete, the regenerated

unit will enter Standby. Standby on each tank is controlled by the lower

drive output terminals on the NXT circuit board.

14 Demand

Recall

2, 3, or 4 Immediate: All Meters Meter input is required on each tank. Unit #1 will begin In Service with

#2, #3, and #4 (if installed) will begin in Standby. At least one unit is

In Service at all times. When flow rate to the Primary Service Unit

increases to a user specified rate, the next unit in sequence will move

from Standby to Service. As the flow rate falls below the user specified

rate subsequent tanks will return to Standby. When the Primary

Service Unit regenerates, the next unit in sequence will become

the new Primary Service Unit. As each units capacity is reached the

controller will initiate a Regeneration of that unit. Depending on the

number of units in the system, and flow rate demand the regenerated

unit will then be placed either into Standby or Service. Only one unit

will be in Regeneration at a time.

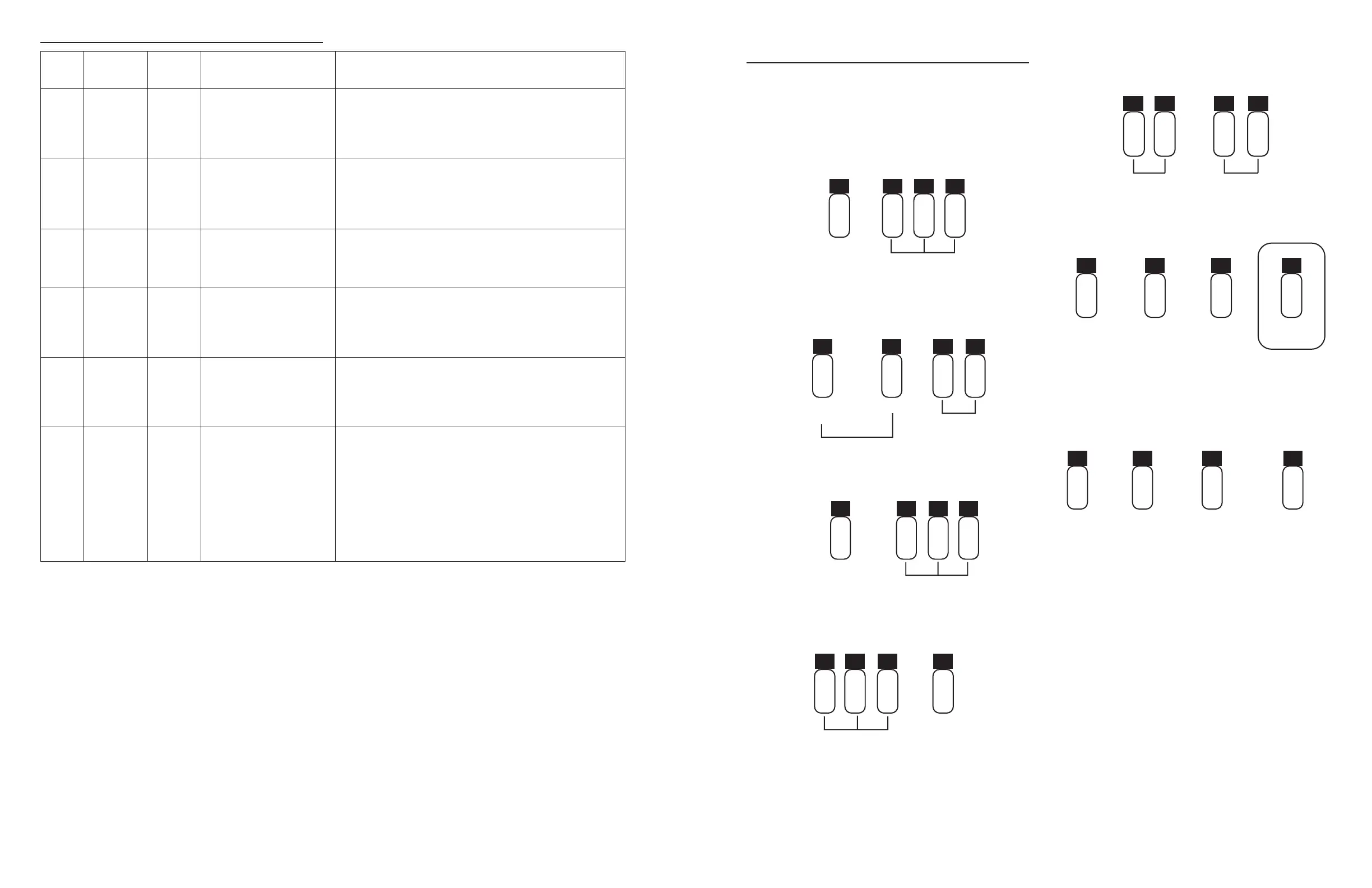

SYSTEM OPERATION IN SERVICE

(SYSTEM 14-DEMAND RECALL)

The system operates as part of a multi-valve regeneration

system.

Each valve in the system will have an active flow meter input,

even in Standby.

The number of valves in service depends on the flow rate.

Examples of a Four-Unit System:

1. One Valve is in service at all times (the "primary valve").

In Service

(Primary Tank)

Standby

123 4

2. The total flow rate to the primary valve increased past

the first trip point programmed rate. The flow stayed past

the trip point delayed time. The next valve (least volume

remaining) changes from Standby to In Service. This valve

then splits the total flow between two meters.

In Service

1234

Standby

First Trip Point

(Primary Valve)

Total Flow Split

Between Two Meters

3. The flow rate demand decreased below the first trip point.

The valve returns to Standby.

Standby

Flow Rate Demand

Below First Trip Point

(Primary Valve)

123 4

4. Total flow rate demand increased past a second trip point

programmed rate. The second and third valve (least volume

remaining) changes from Standby to In Service. The total

flow is split between the three meters.

Standby

Flow Split Between

Three Meters

12 3 4

5. The third valves returns to stand by as demand decreases

past the second trip point.

Standby

Flow Split Between

Two Meters

1 2 34

6. Valves return to stand by due to decreased total flow rate

and trip points programmed. The valve with the most

remaining volume will be the first to go into Standby.

Full Capacity

4th in Standby

(Primary Valve)

3/4 Capacity

3rd in Standby

1 2

1/2 Capacity

2nd in Standby

1/4 Capacity

1st in Standby

7. The primary valve regenerates. The next valve with the least

remaining volume becomes the new primary valve. The

valve with the next least volume remaining will be the first

trip point programmed rate. Valves continue operating in

this order.

Full Capacity

3/4 Capacity

3rd in Standby

1 2

1/2 Capacity

First Trip Point

1/4 Capacity

New Primary Tank

System Operation in Regeneration:

If two valves are In Service and both reach

Volume Remaining = 0, the other two valves will shift from

Standby to In Service. The lead valve with

Volume Remaining = 0 will start regeneration. The second valve

with Volume Remaining = 0 will enter Standby. If flow increases

past the trip point a third valve needs to enter In Service. The

valve in Standby with Volume Remaining = 0 will shift into

In Service to maintain a steady flow. Operating for extended

periods in this mode may degrade the water quality.

4 • Fleck 3200 NXT Fleck 3200 NXT • 5

Loading...

Loading...