PAL-AT Installation Manual

33

cable through the junction box and conduit.

9. Splice the sensor cable to the continuous pull rope using the method described in section 4.3, "Cable

Splices".

10. At least two workers are required to pull sensor cable. Work should proceed continuously from pull

point to pull point. At the lowest elevation between two pull points, one person should slowly pull on

the pull rope. At the higher elevation pull point, the second person should carefully play out the cable

while pushing it into the interstitial air space. This push/pull action significantly reduces the pulling

force required to install the cable. If a problem does arise, the workers must be able to signal each

other quickly. Walkie-talkies are recommended so communication can occur to prevent cable damage.

11. The pulling force should never exceed 50 lb [23 kg]. If a snag is encountered, carefully work the

cable back and forth in an attempt to clear the cable. If the snag cannot be cleared, contact PermAlert's

Field Service Department for assistance.

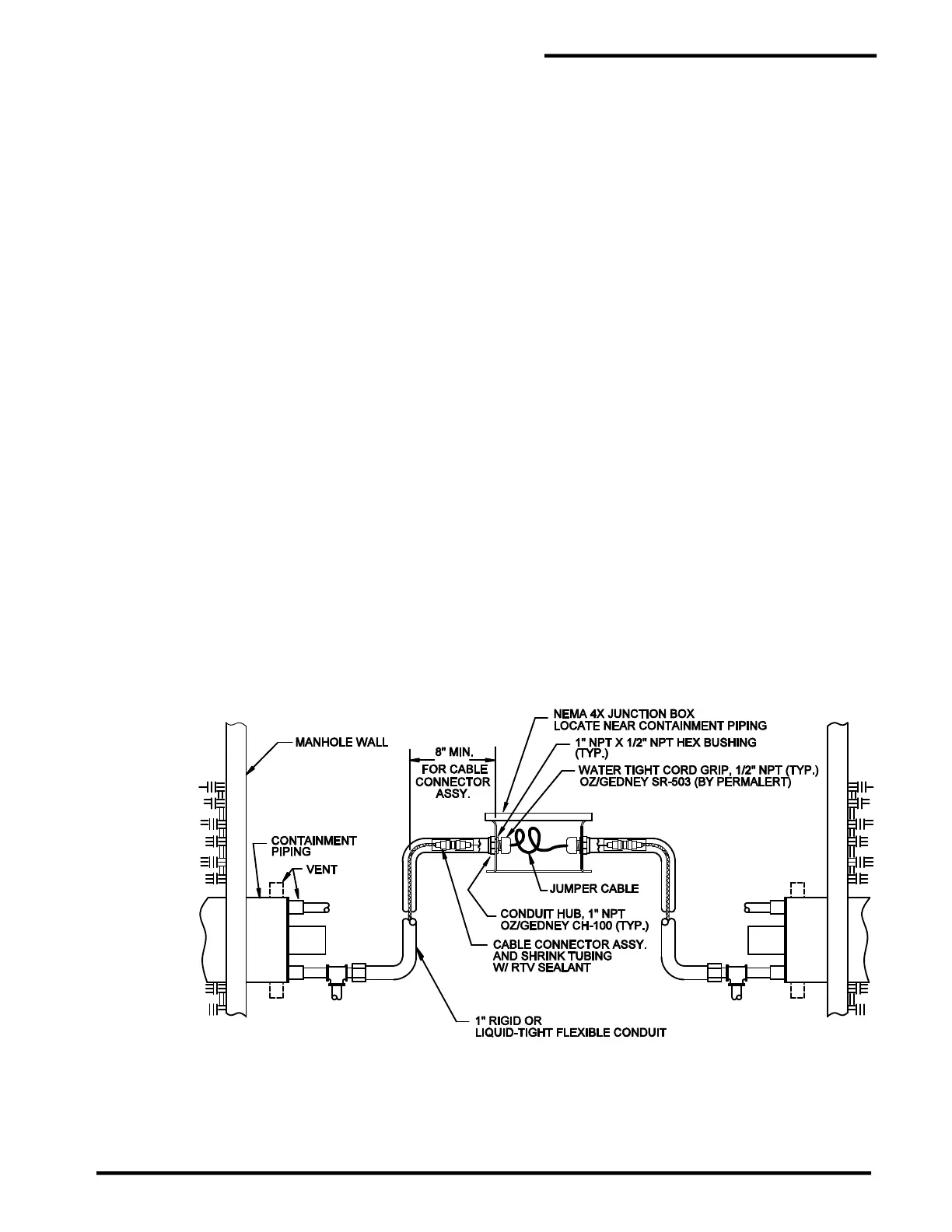

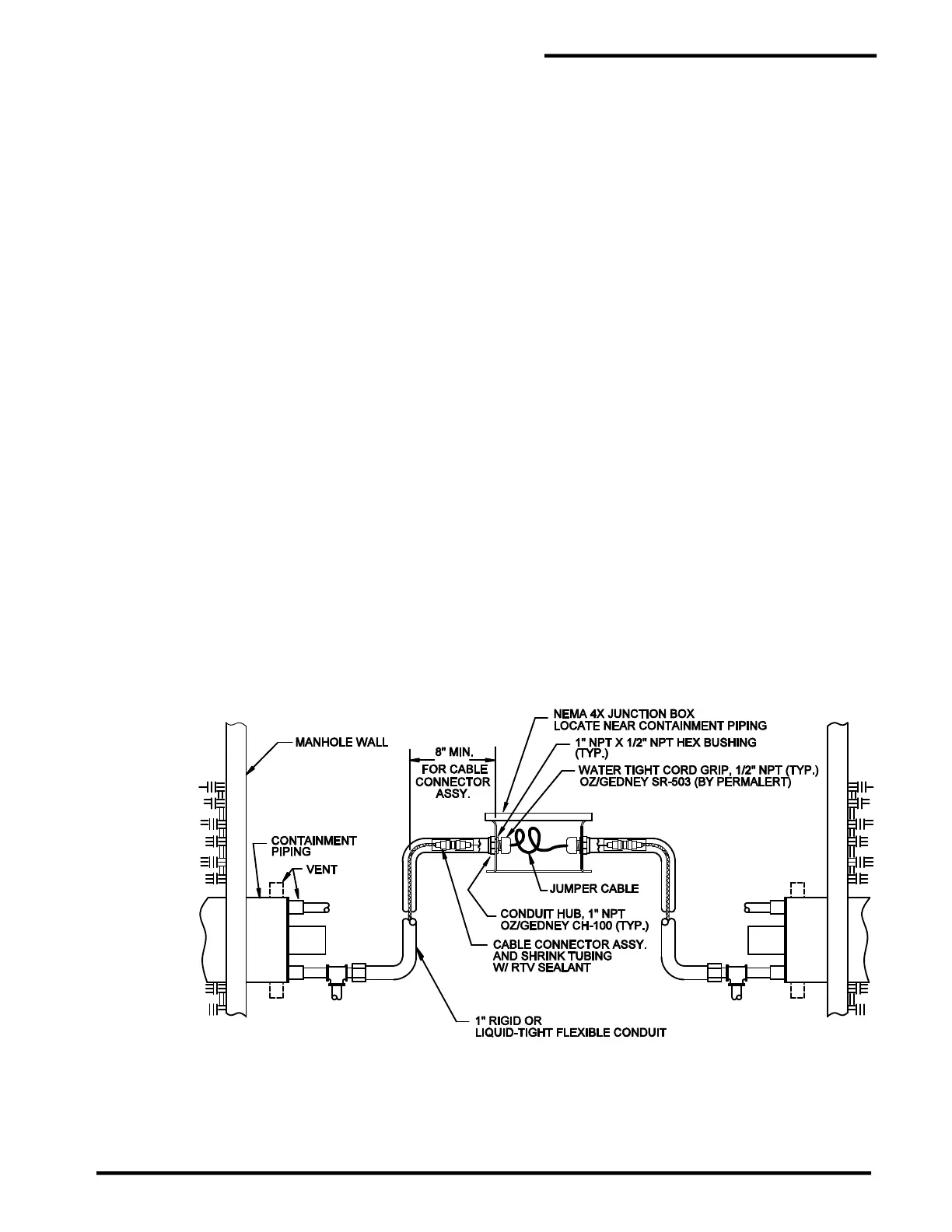

12. Where electrical conduit and junction boxes are required, use watertight NEMA 4X [IP66] boxes and

mount per the instructions contained in this guide. Temporarily pull enough sensor cable out of the

secondary containment and into the junction box (approximately 2' [600 mm]) to allow installation of

cable connectors (see figure 5-2). Make sure the bushings and cord grips are slipped on the

jumper cable before installing the cable connectors. Attach the cable connectors, test them, and

push the assemblies into the electrical conduits. Thread and tighten the cord grips making a watertight

seal against the jumper cable. The conduit termination points must be sealed. Do not leave conduit

termination points open, or moisture may enter and wet the sensor cable.

13. The ends of all cables should be kept dry during installation. If the cable ends are submerged

in water, capillary action will wick water into the center conductor. This could cause corrosion

and shorten the life of the cable.

14. If TFH cable is installed, the ends of the cable must be immediately sealed with the shrink tube

caps supplied by PermAlert to prevent water from entering the cable under the jacket. Make

sure the polyester overbraid is not under the shrink cap to insure a good seal. If water is allowed to

enter the ends of TFH cable, it must be replaced.

Figure 5-2

Cable Connections with Electrical Conduit and Junction Boxes

15. In contained pipe systems where branch runs and main runs are monitored, jumper cable can be used

to return to the main from the branch. For these installations, PermAlert can furnish a cable routing

Loading...

Loading...