PAL-AT Installation Manual

52

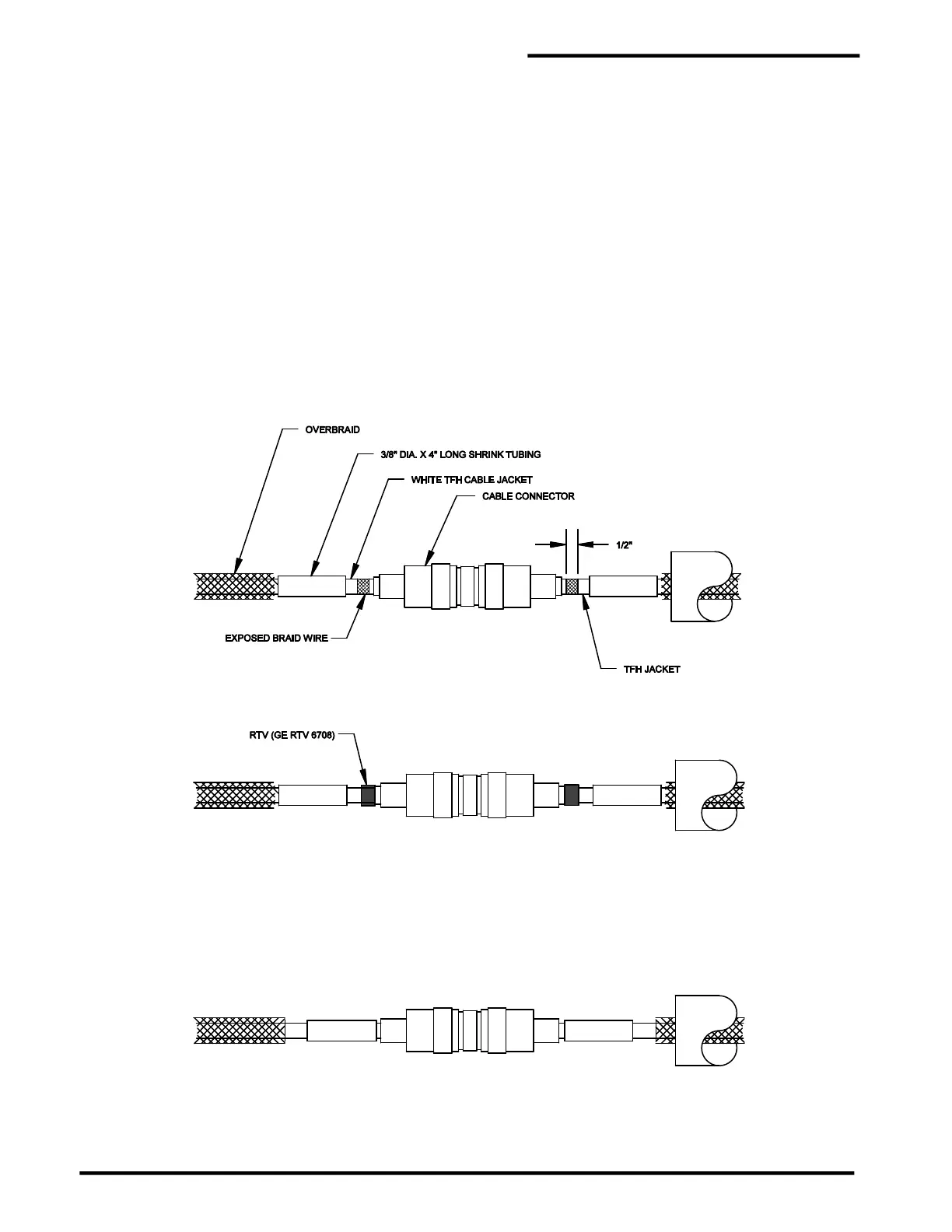

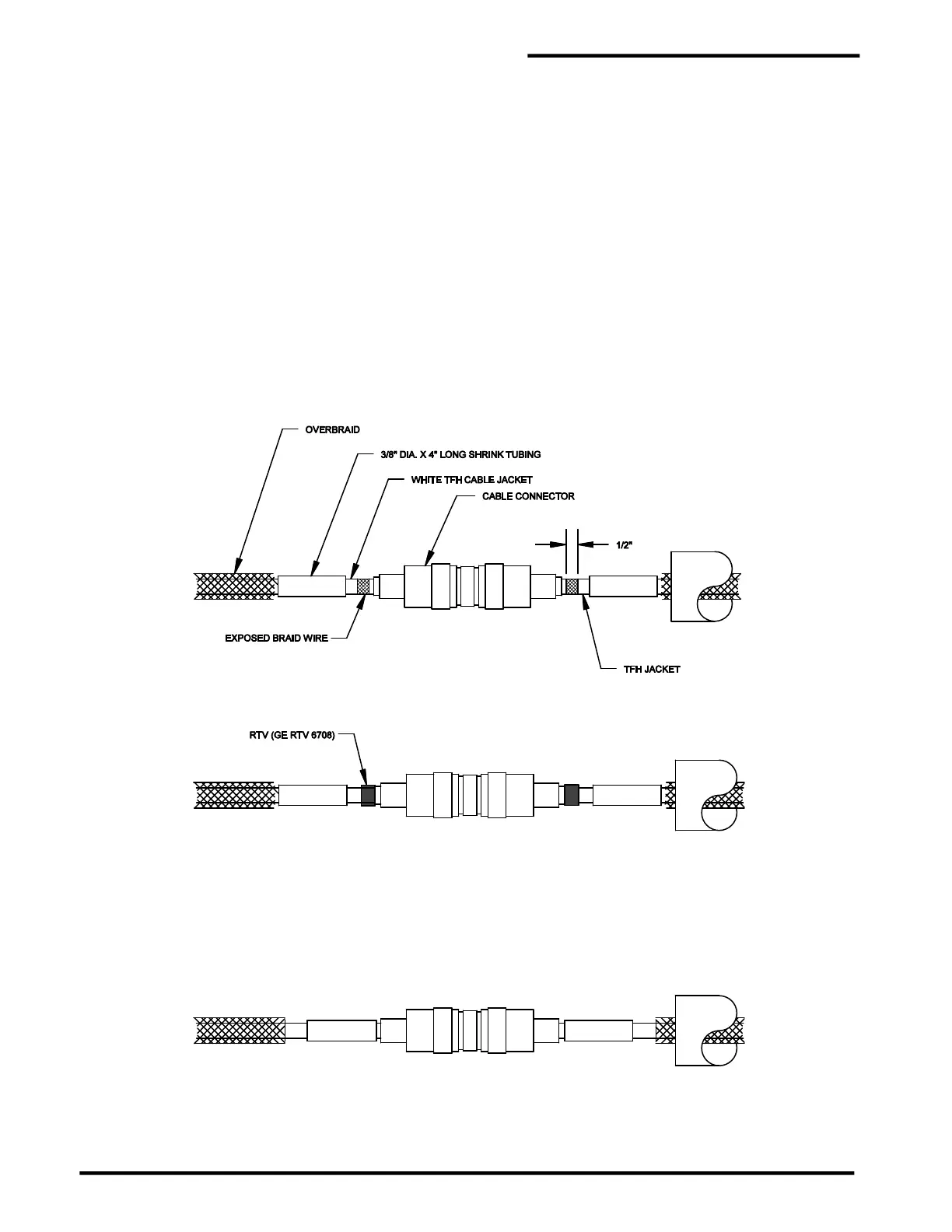

8.3 Shrink Tubing

All cable connectors installed in inaccessible locations or locations subject to frequent leaks or

corrosive environments must be encapsulated with shrink tubing. This applies to sensor cables

and jumper cables. Connectors used for calibration points should not be sealed until the system has

been brought online unless they may be exposed to water before start-up.

8.3.1 Cable Type TFH

1. The TFH cable connector assemblies must be encapsulated in watertight shrink tubing. Test

connectors according to the "Cable and Connector Testing Procedures" before heating the shrink

tubing. Connectors used for calibration points must be kept dry until the system has been

commissioned. After commissioning, the shrink tubing should be installed. If water is allowed

to enter the end of the cable and get under the jacket, the cable must be replaced.

2. Install the shrink tubing in accordance with the following steps:

Step A Slide the overbraid and cable jacket back from the reducing adapter, to expose ½" [12 mm] of

braid wire. Smooth the excess cable jacket away from the connector, so there is at least 5" [125

mm] of smooth surface adjacent to the connector. If the sensor cable is being connected to a

jumper cable, skip steps A and B for jumper cable.

Step B Place a 1/4" [6 mm] bead of non-corrosive RTV sealant around the cable on the exposed braid

wire.

Step C Slide the 4" [100 mm] long shrink tubing to the reducing adapter, if the CASTD connector is used.

Make sure there are no wrinkles in the cable jacket. Make sure the shrink tubing does not overlap

the reducing adapter. Slide the shrink tubing over the outer crimp ferrule to the back of the

connector body if the CAGOLD crimp style connector is used. Heat the shrink tubing with a heat

gun until it has fully shrunk and adhesive oozes out the end. Do not disturb the assembly until the

shrink tubing has cooled (approximately 5-10 minutes).

Loading...

Loading...