34

Go to cover page

170B6 LCD

All units that are returnedfor service or repair mustpass the

originalmanufacturessafety tests. Safety testingrequiresboth

and testing.Hipot Ground Continuity

HI-POT TEST INSTRUCTION

1.Application requirements

2.

1.1 All mains operated products mustpass the Hi-Pot testas

describedinthis instruction.

1.2 This test must be performed again after thecovershave

been refittedfollowingthe repair, inspection or modification

of theproduct.

2.1Connect

ingconditions

2.1.1 Thetest specified must be appliedbetween the parallel-

bladeplugof the mainscord and all accessible metal

parts of theproduct.

2.1.2 Before carryingoutthetest, reliableconductive

connections mus

t beensured and thereafter be

maintained throughoutthetest period.

2.1.3 The mains switch(es) must be in the "ON" position.

2.2 Test Requirements

All productsshould be HiPot and Ground Continuity tested

as

follows:

Test 2820VDC 1700VDC Testcurrent:

voltage (2000VAC)(1200VAC) 25A,AC

Testtime:

Testtime3seconds 1 second 3 seconds(min.)

(min.) Resistance

required:

Trip set at 100 uA 5 mA <=0.09+Rohm,

current for Max. R is the

(Tester) limitation; set resistance of

at 0.1 uA for the mains cord.

Min. Limitation

Ramp set at 2

time seconds

(Tester)

Test method

Condition HiPot Test for HiPot Test for Ground Continuity

productswhere productswhere Testrequirement

the mains inputthe mains input is

range is Full 110VAC(USA

range(or 220V type)

AC)

2.2.1 The minimum test durationfor Quality ControlInspector

must be1minute.

2.2.2 Thetestvoltage must be maintainedwithin the specified

voltage + 5%.

2.2.3 There must be no breakdown duringthetest.

2.2.4 Thegrounding bladeorpin ofmains p

lug must be

conductedwith accessible metal parts.

3. Equipments and Connection

3.1. Equipments

For example :

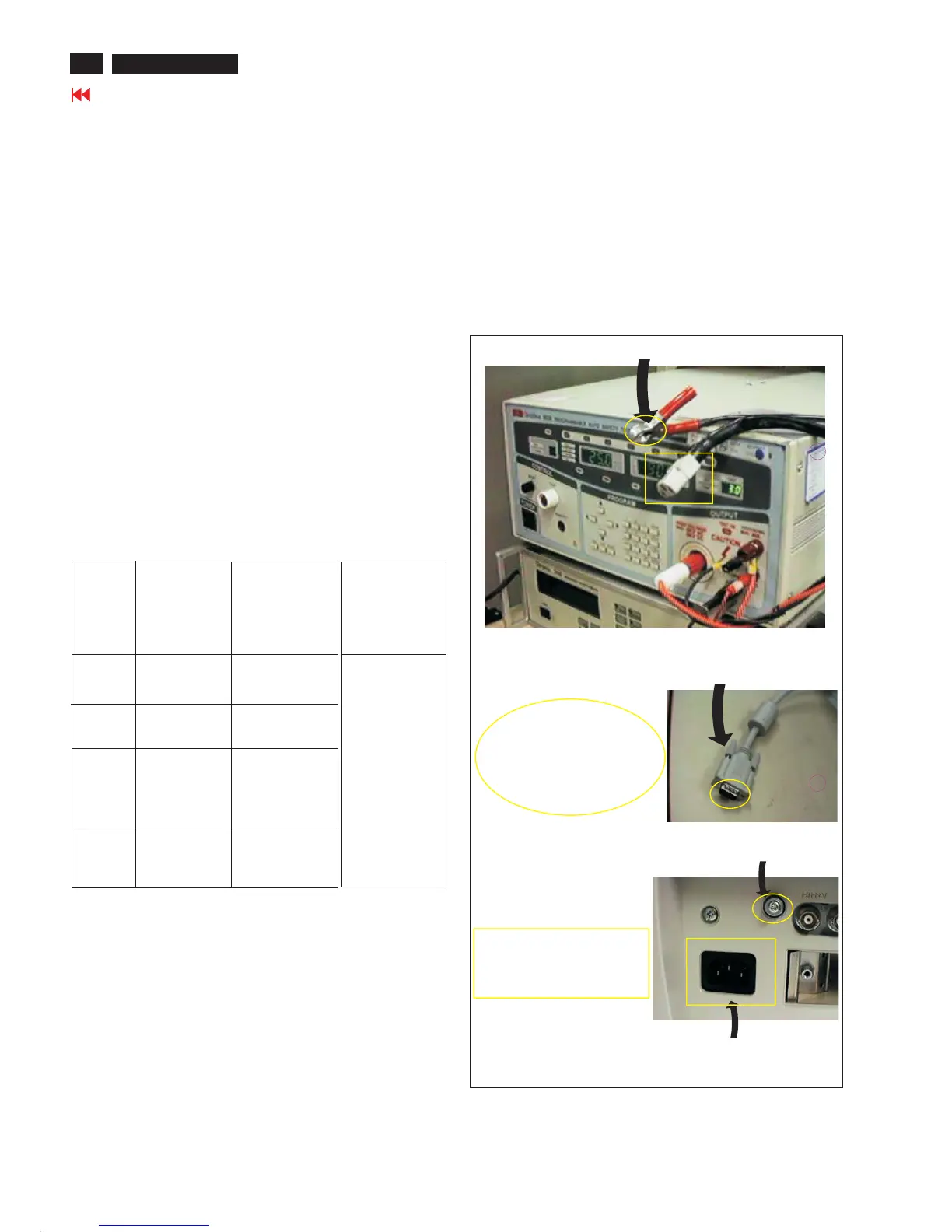

- ChenHwa 9032 PROGRAMMABLE AUTO SAFETY

TESTER

- ChenHwa 510B Digital GroundingContinuityTester

- ChenHwa 901 (AC Hi-pot test), 902(AC, DC Hi-pot test)

Withstanding Tester

3.2. Connection

4. Recording

Hipot and Ground Continuity testing records have to be kept

for a period of 10 years.

*Turn on thepower switch ofmonitor before Hipot and

Ground Continuity testing.

Connect the "video cable"

or "grounding screw"

to the CLIP on your tester.

Video cable

(Rear view of monitor)

Connect the power cord

to the monitor.

Grounding screw

Power outlet

(ChenHwa 9032 tester)

Clip

Clip

SafetyTest Requirements

Loading...

Loading...