LANCE

II SERVICE

MANUAL

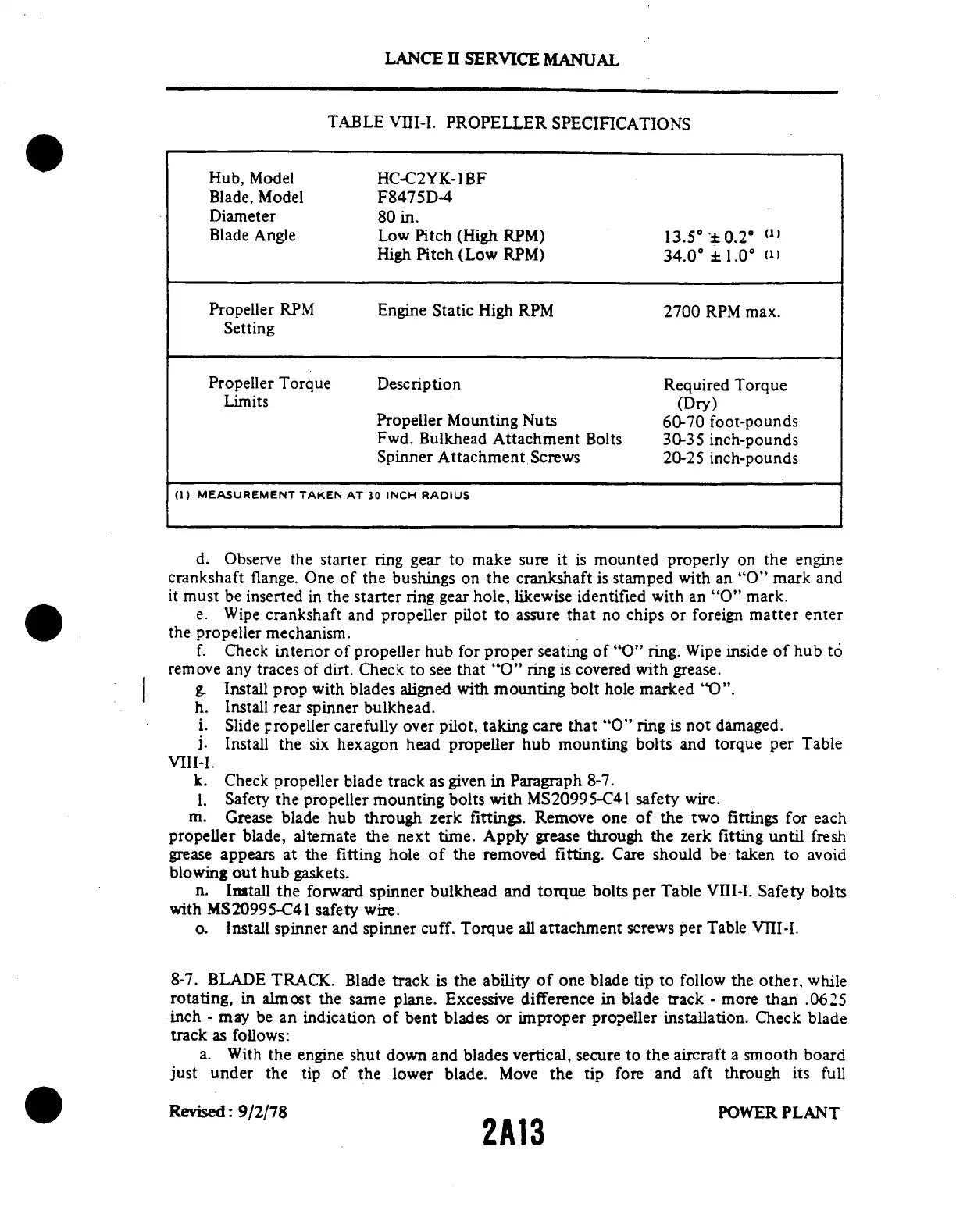

TABLE

VIII-I.

PROPELLER

SPECIFICATIONS

Hub,

Model

HC-C2YK-1BF

Blade, Model

F8475D-4

Diameter

80 in.

Blade

Angle

Low Pitch (High

RPM)

13.5

± 0.2

°

()

High Pitch (Low

RPM)

34.0

°

1.0

°

(1)

Propeller

RPM

Engine

Static

High RPM

2700

RPM max.

Setting

Propeller

Torque

Description

Required

Torque

Limits

(Dry)

Propeller Mounting

Nuts

60-70 foot-pounds

Fwd. Bulkhead

Attachment

Bolts

30-35

inch-pounds

Spinner

Attachment

Screws

20-25

inch-pounds

(1) MEASUREMENT

TAKEN AT 30

INCH RADIUS

d. Observe

the starter

ring gear to make

sure it is mounted

properly on the

engine

crankshaft flange. One of the

bushings on the crankshaft is stamped

with an "0" mark and

it must

be inserted in the starter ring gear

hole, likewise identified with an

"0" mark.

e. Wipe crankshaft

and propeller

pilot to assure that

no chips or foreign

matter enter

the propeller mechanism.

f. Check interior of propeller

hub for proper seating of "0" ring.

Wipe inside of hub to

remove

any traces of dirt. Check to

see that "O" ring is covered with

grease.

g. Install prop with blades

aligned with mounting bolt hole

marked "O".

h.

Install rear spinner

bulkhead.

i.

Slide propeller

carefully over pilot,

taking care that

"O" ring is not

damaged.

j. Install the six

hexagon head propeller

hub mounting

bolts and torque

per Table

VIII-I.

k.

Check propeller

blade track

as given

in Paragraph

8-7.

1. Safety the propeller

mounting bolts with

MS20995-C41 safety wire.

m. Grease blade

hub through

zerk fittings. Remove

one of the two

fittings for each

propeller

blade, alternate

the next time.

Apply grease through

the zerk fitting

until fresh

grease appears

at the fitting

hole of the removed

fitting. Care should

be taken to

avoid

blowing out hub gaskets.

n. Install

the

forward

spinner bulkhead

and torque

bolts per

Table

VIII-I. Safety

bolts

with

MS20995-C41

safety wire.

o. Install spinner and spinner

cuff. Torque all attachment

screws per Table VIII-I.

8-7. BLADE

TRACK. Blade

track is

the ability of

one blade

tip to follow

the other, while

rotating, in

almost the

same plane.

Excessive difference

in blade

track - more

than .0625

inch

- may be an

indication of

bent blades

or improper

propeller installation.

Check

blade

track

as follows:

a. With the

engine shut down and blades vertical,

secure to the aircraft a smooth board

just under

the tip of the lower blade. Move

the tip fore and aft through its

full

Revised:

9/2/78

POWER PLANT

2A13

Loading...

Loading...