4-10 SV61831 Rev. A DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

4 • Troubleshooting/Diagnostics

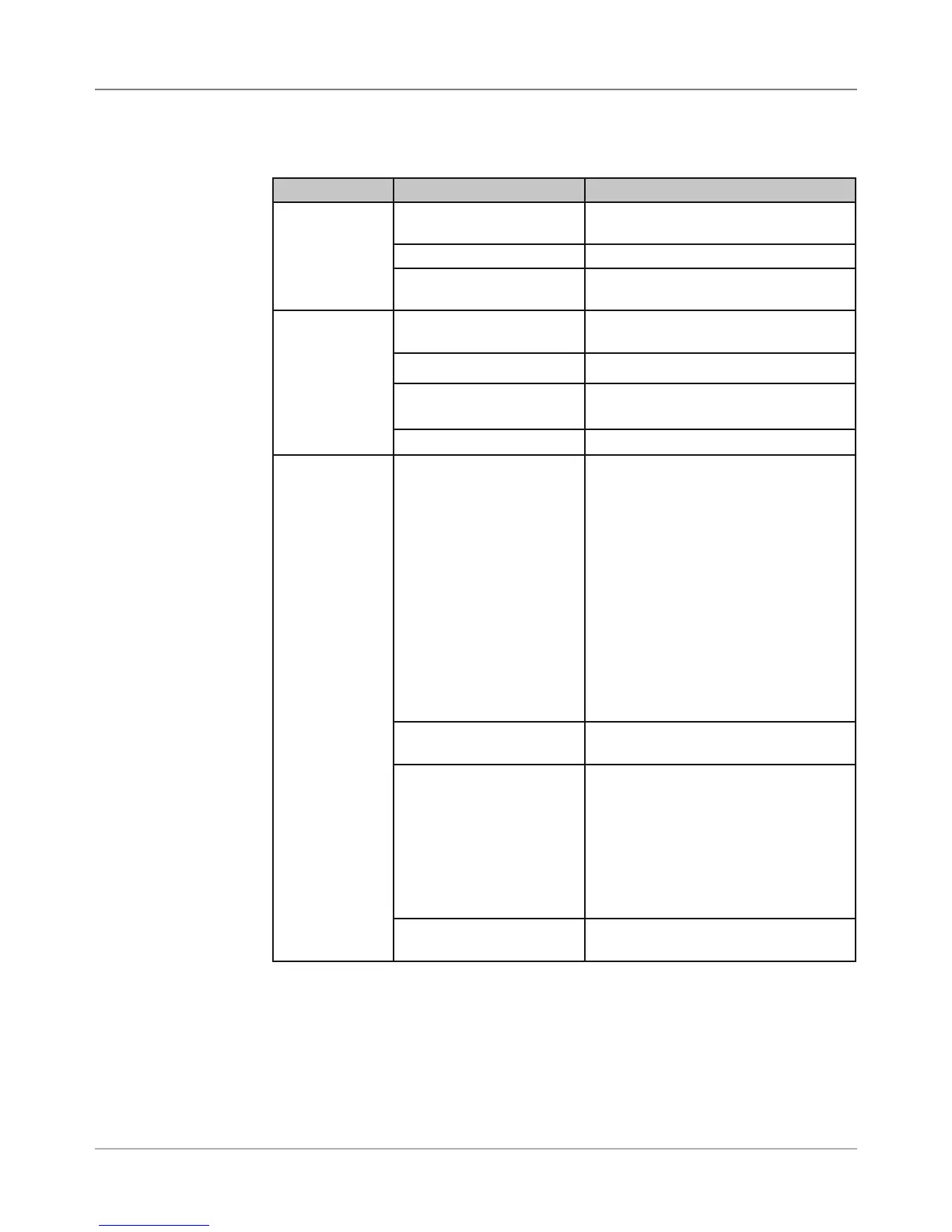

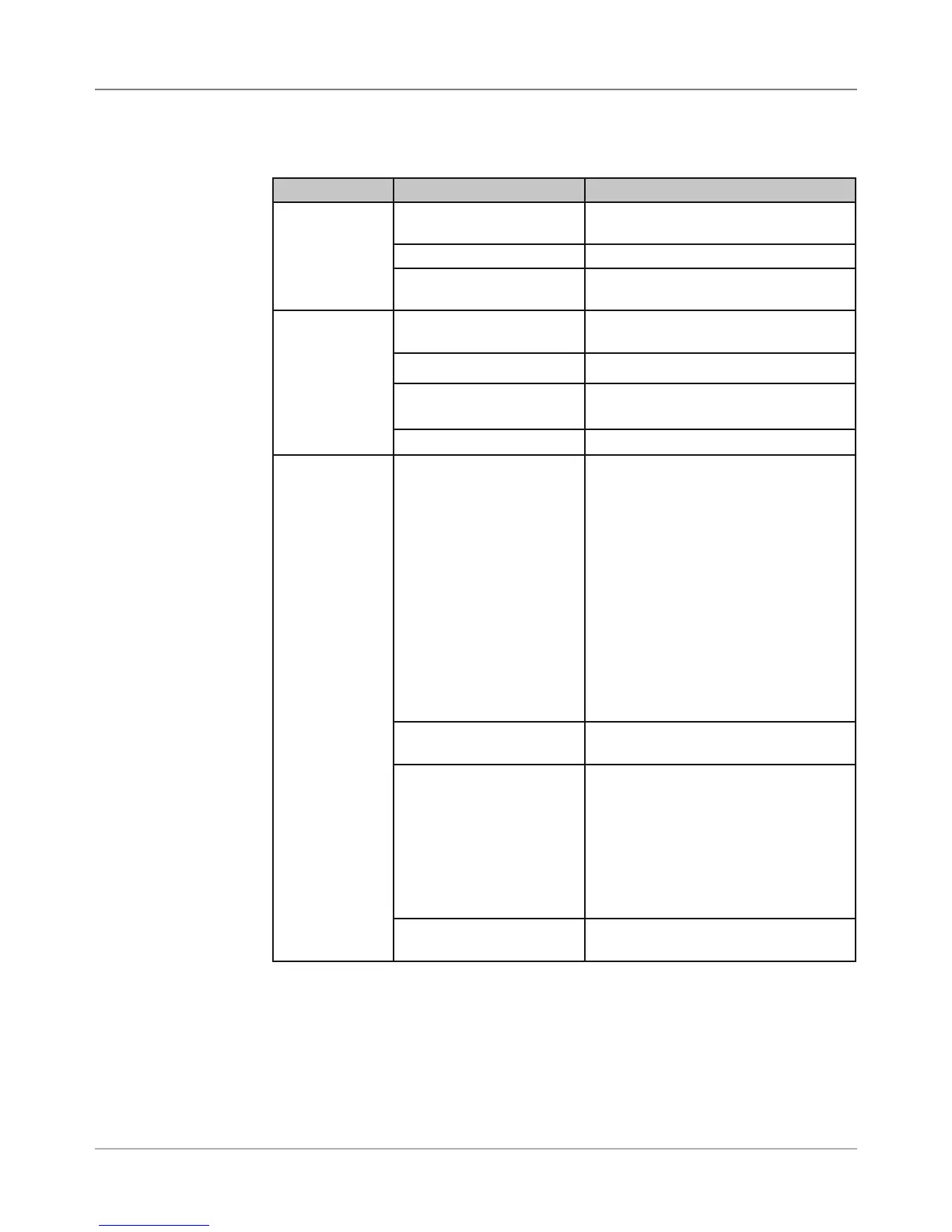

Table 4-4 Print Quality Problems

Symptom Possible Cause Solution

Ink Print Qual-

ity not Sharp

Envelope thickness ad-

justment incorrect

Adjust lever to lower print head

Material out of spec Change to typical white wove bonded

Contaminated mainte-

nance station

Clean the caps and wipe with damp

cloth or paper towel

Ink streaking

on Media

Envelope thickness ad-

justment incorrect

Adjust lever to raise print head

Exit idler rollers dirty Clean rollers with water to remove ink

Print head needs purging Run “Purge Print Head” from Setup

Menu

The print cartridge is dirty Clean the cartridge

Non-Uniform

Print

Quality

Print Head Holder broken Check the print head holder for

broken pins. Replace print head

drive board if pins are broken. NOTE:

When trying to decide if print head

driver board should be replace or

not, run “Test Print Head” from Setup

Menu, replace the ink cartridge with

a new one, then run the print head

test again. If the gaps are consistent

with different ink cartridge, then the

print head driver board needs to be

replaced (when there is no physical

sign that the print head driver board

is damaged).

Print head holder Check that flex circuit dimples are not

crushed

Multiple print nozzles not

working

Run “Purge Print Head“ from Setup

Menu, then run “Test Print Head”. If

not helpful, swap ink cartridge with

known good one. If the same nozzles

are out, check the ribbon cable going

to print head cartridge (it may have

lost power to nozzles). If cable is fine,

check print head board.

Print Head If gap appears in test pattern, replace

print head.

4.3

Troubleshooting

Tables

Loading...

Loading...