6

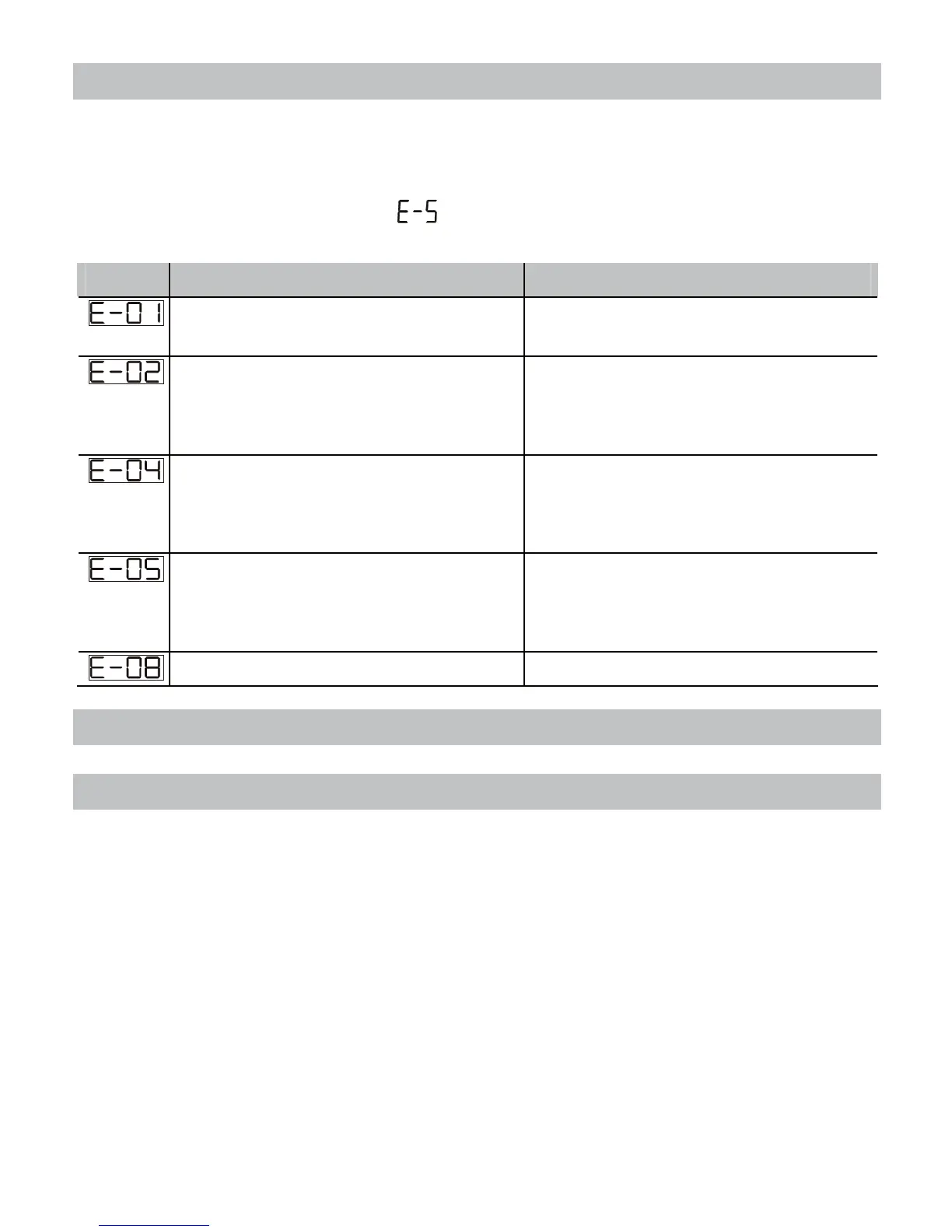

4 - LIST OF ERROR MESSAGES

If the plant does not work properly, the controller stops the

running cycle and shows the anomaly.

For example the controller will notice the failure of a

thermocouple displaying

(flashing).

For further error signs check the list below

.

Error Cause Do

Programming error

EPROM.

Contact technical service

Cold junction failure or

room temperature out of

range

Contact technical service

Wrong configuration data.

Possible lost of calibration

values

Check configuration

parameters

Open thermocouple or

room temperature out of

range

Check sensors connection

and their integrity

Missing calibration data Contact technical service

5 - SECTION FOR INSTALLERS

6 - INTRODUCTION

Thanks for choosing a Pixsys Controllers. Various models with 3-4

digits display make the controller suitable for a wide range of

applications with temperature, humidity, pressure sensors and

linear potentiometers. Output options include two relays and SSR,

but the unit is configurable also as visualizer/indicator for

applications not requiring control or alarm outputs. PID control with

Autotuning function enables to adapt control algorithm to the plant.

For applications with linear potentiometers the function LATCH ON

allows a quick calibration. Memory-card is available to copy

configuration parameters and to keep record of them.

The tables below allow to select the required model.

Loading...

Loading...