5.8

Engine Systems

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

Cylinder Honing

The cylinder bore must be de-glazed whenever new piston

rings are installed. A light honing with fine stones removes

only a very small amount of material. A proper crosshatch

pattern is important to provide a surface that will hold oil,

and allow the rings to seat properly. If the crosshatch is too

steep, oil retention will be reduced. A crosshatch angle

which is too shallow will cause ring vibration, poor sealing,

and overheating of the rings due to blow-by and reduced

contact with the cylinder wall. Service life of the pistons

and rings will be greatly reduced.

NOTE: A Nicasil cylinder can be lightly honed with a

320 grit stone hone but can not be oversized.

Honing Tools

The following tools are recommended:

• Ammco 3950 Hone Kit - SPX PN: 2870303

• Honing Oil - SPX PN: 2870588

• Oversize 320 grit stone (69.8 - 92.8mm) - SPX PN:

PU-49876

Honing Procedure

1. Wash the cylinder with cleaning solvent.

2. Clamp the cylinder in a soft jawed vise by the cylinder

studs.

3. Place hone in cylinder and tighten stone adjusting

knob until stone contacts the cylinder walls (DO NOT

OVERTIGHTEN).

4. Apply honing oil to the stones and cylinder walls. Wet

honing removes more material faster and leaves a

more distinct pattern in the bore.

5. Using a 1/2" (13 mm) drill motor rotating at a speed of

300-500 RPM, run the hone in and out of the cylinder

rapidly until cutting tension decreases. Remember to

keep the hone driveshaft centered to prevent edge

loading and always bring the stone approximately 1/

2" (1.2 cm) beyond the bore at the end of each stroke.

6. Release the hone at regular intervals to inspect bore

size and finish.

Honing To Oversize (Iron-Lined Cylinders)

If cylinder wear or damage is excessive, it will be

necessary to oversize the cylinder using a new oversize

piston and rings. This may be accomplished by either

boring the cylinder and then finish honing to the final bore

size, or by rough honing followed by finish honing.

For oversize honing always wet hone using honing oil and

a coarse roughing stone. Measure the new piston at room

temperature (see piston measurement) and rough hone to

the size of the piston or slightly larger. Always leave .002"

- .003" (.05 - .07 mm) for finish honing. Complete the sizing

with fine grit stones to provide the proper cross-hatch

finish and required piston clearance.

Inspect cylinder for taper and out-of-round. Taper or out-

of-round on the finished bore should not exceed .0004"

(.002mm).

NOTE: Portable rigid hones are not recommended for

oversizing cylinders, cylinder boring, and finish

honing. The use of an arbor type honing machine is

recommended. Always check piston to cylinder

clearance and piston ring installed gap after boring /

honing is complete.

Cleaning The Cylinder After Honing

It is very important that the cylinder be thoroughly cleaned

after honing to remove all grit material. Wash the cylinder

in a solvent, then in hot soapy water. Pay close attention

to areas where the cylinder sleeve meets the aluminum

casting (transfer port area). Use electrical contact cleaner

if necessary to clean these areas. Rinse thoroughly, dry

with compressed air, and oil the bore immediately with

Polaris Premium 2 Cycle Lubricant.

NOTE: Always check piston to cylinder clearance

and piston ring installed gap after honing or boring is

complete.

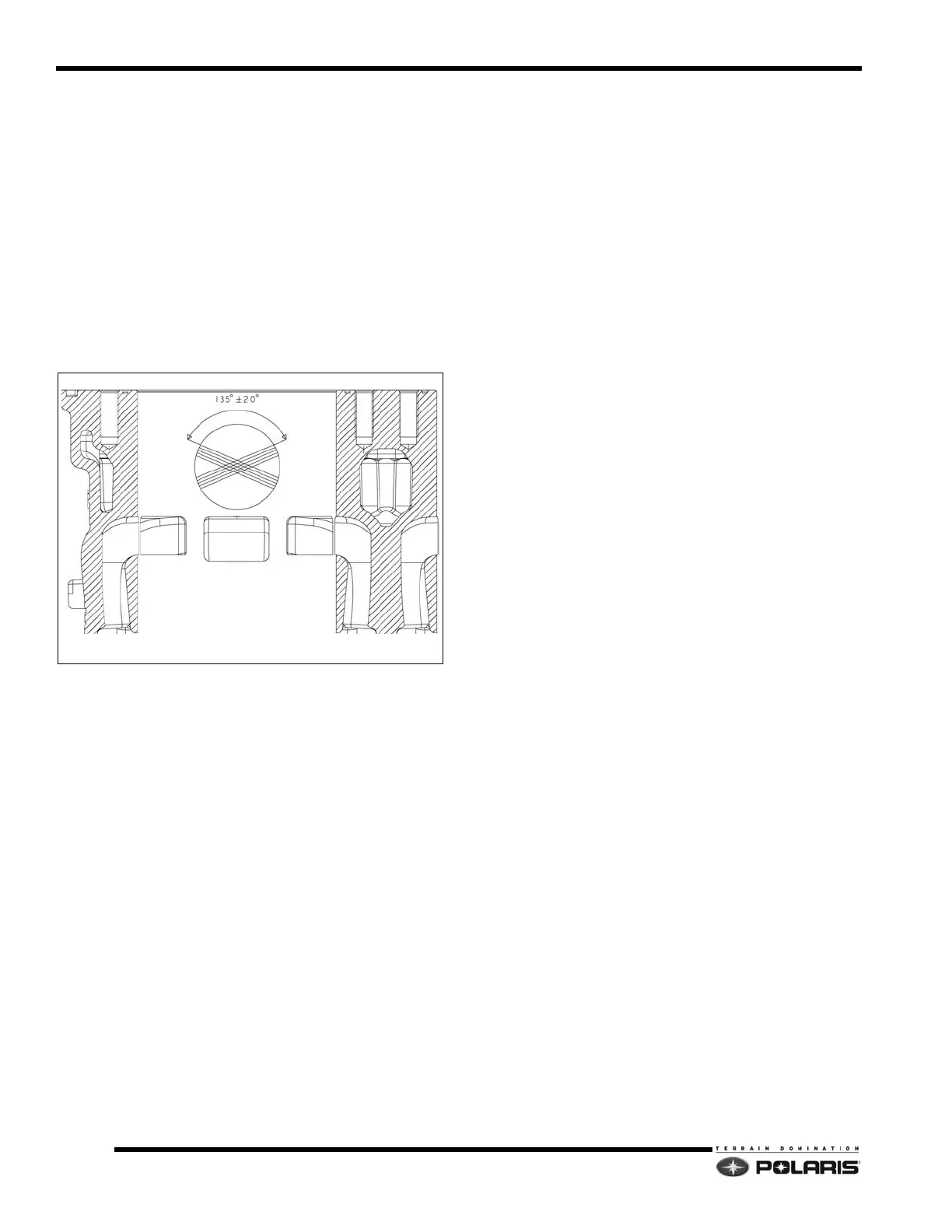

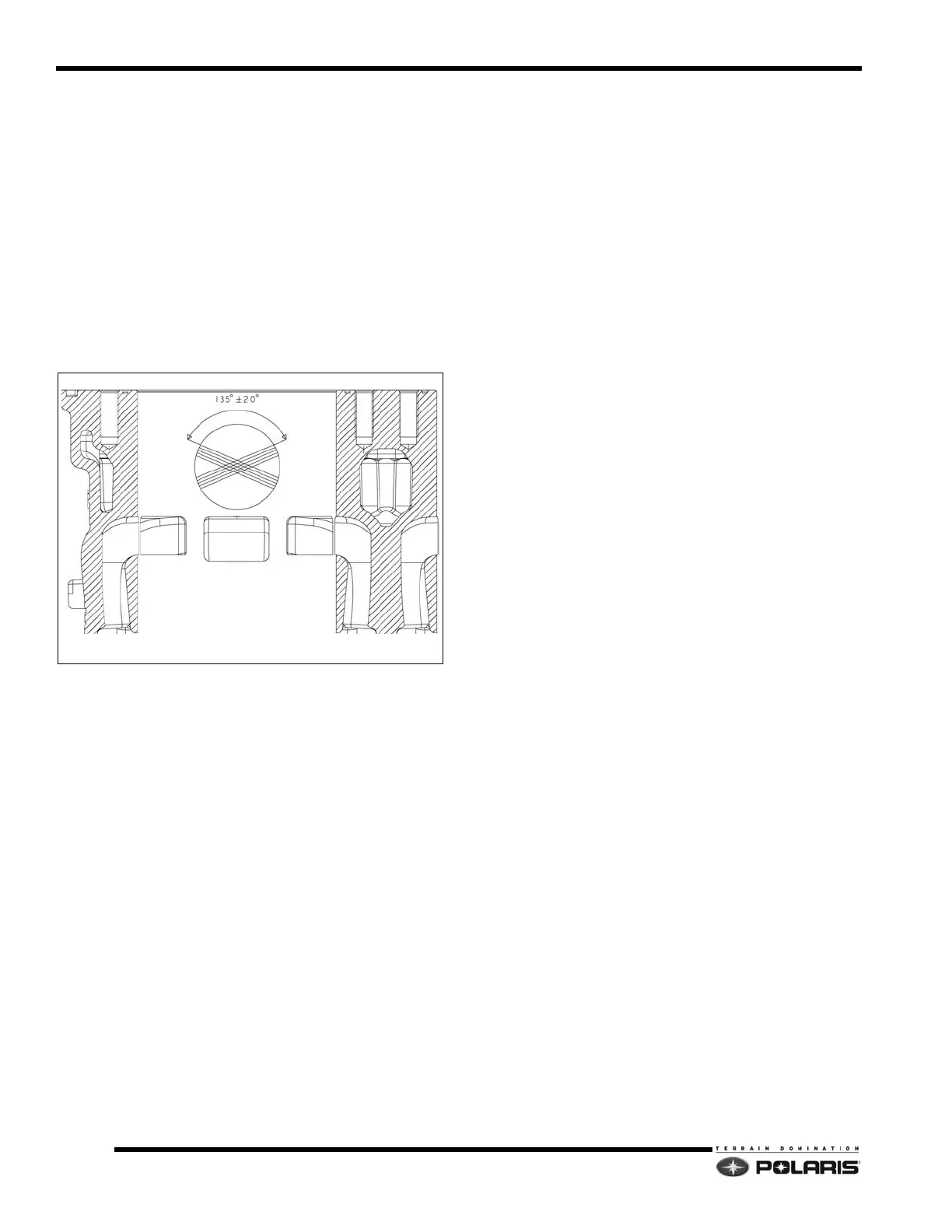

EXAMPLE OF A CROSS HATCH PATTERN

Loading...

Loading...