20-92 PN-0908073 Rev. 11

PS 164-2

THE ART OF WELDING

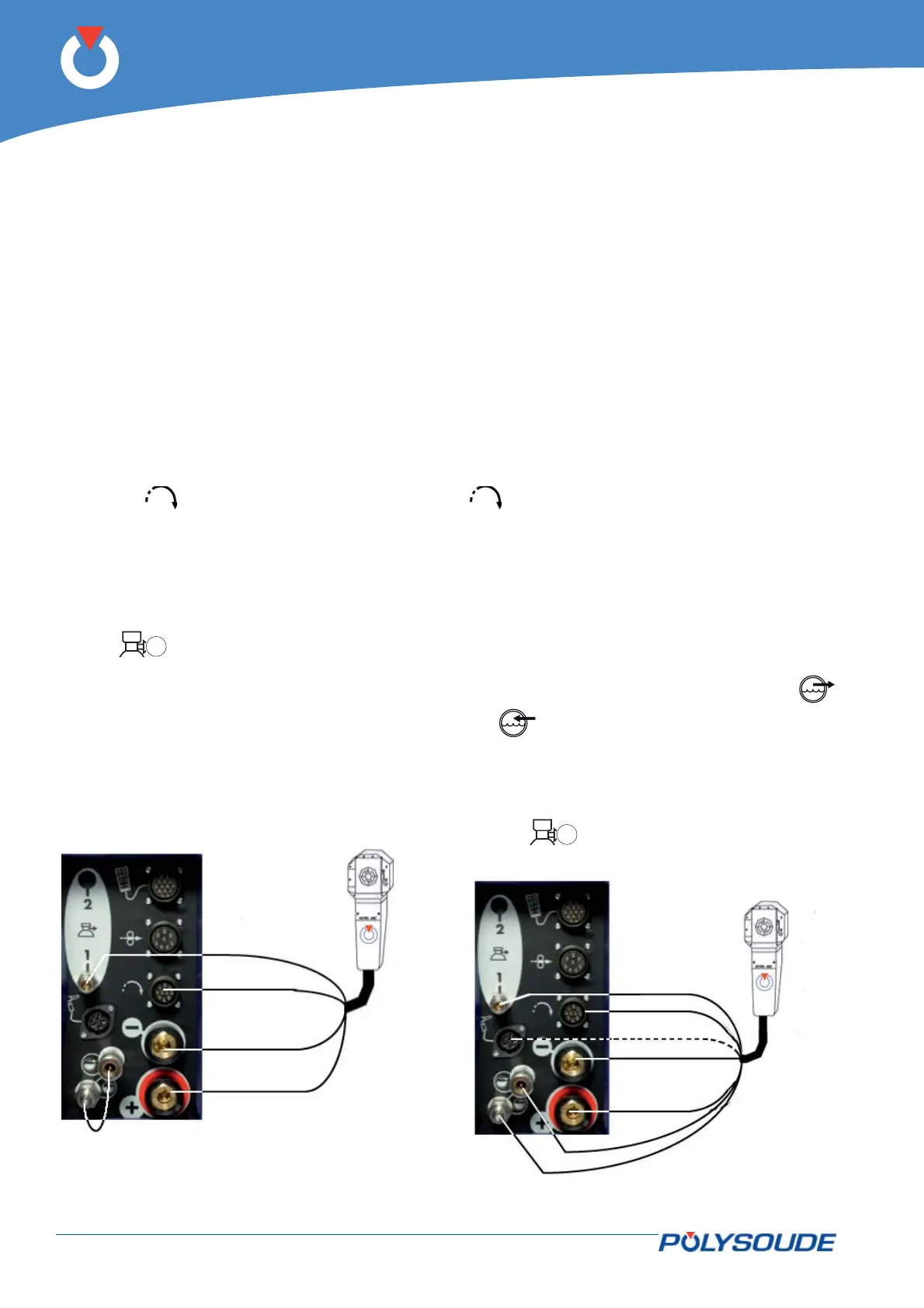

4. 3. 3. Connection of an air cooled closed chamber welding

head

This is the case for type H or UHP Polysoude closed

welding heads.

◊ Connection of the electrode current cable

Connect the current cable on the "-" terminal with

the quick connector, locking it by a short rotation to

the right. This cable is not indicated.

◊ Connection of the current return cable

Connect the current return conductor cable onto the

"+" terminal marked by a red ring. Connection is

made with a quick connector by a short rotation to

the right. This cable is indicated red.

◊ Connection of the rotation motor cable

Connect the cable on the "Rotation" module connec-

tor (symbol

). Make sure that the securing ring

is properly tightened, otherwise the system may not

function correctly

◊ Connection of the torch shielding gas hose

Connection is made with a quickpush type self seal-

ing coupling disconnect fi tting situated at the bottom

left hand corner of the front panel of the PS 164-2

(symbol

1

).

◊ Connection of a bipass plug for the coolant

circuit security for use with air cooled weld-

ing heads.

For UHP before 2003 and H welding heads, it is neces-

sary to introduce the bipass plug to isolate the coo-

ling circuit security in order to avoid a continuously

detected fault.

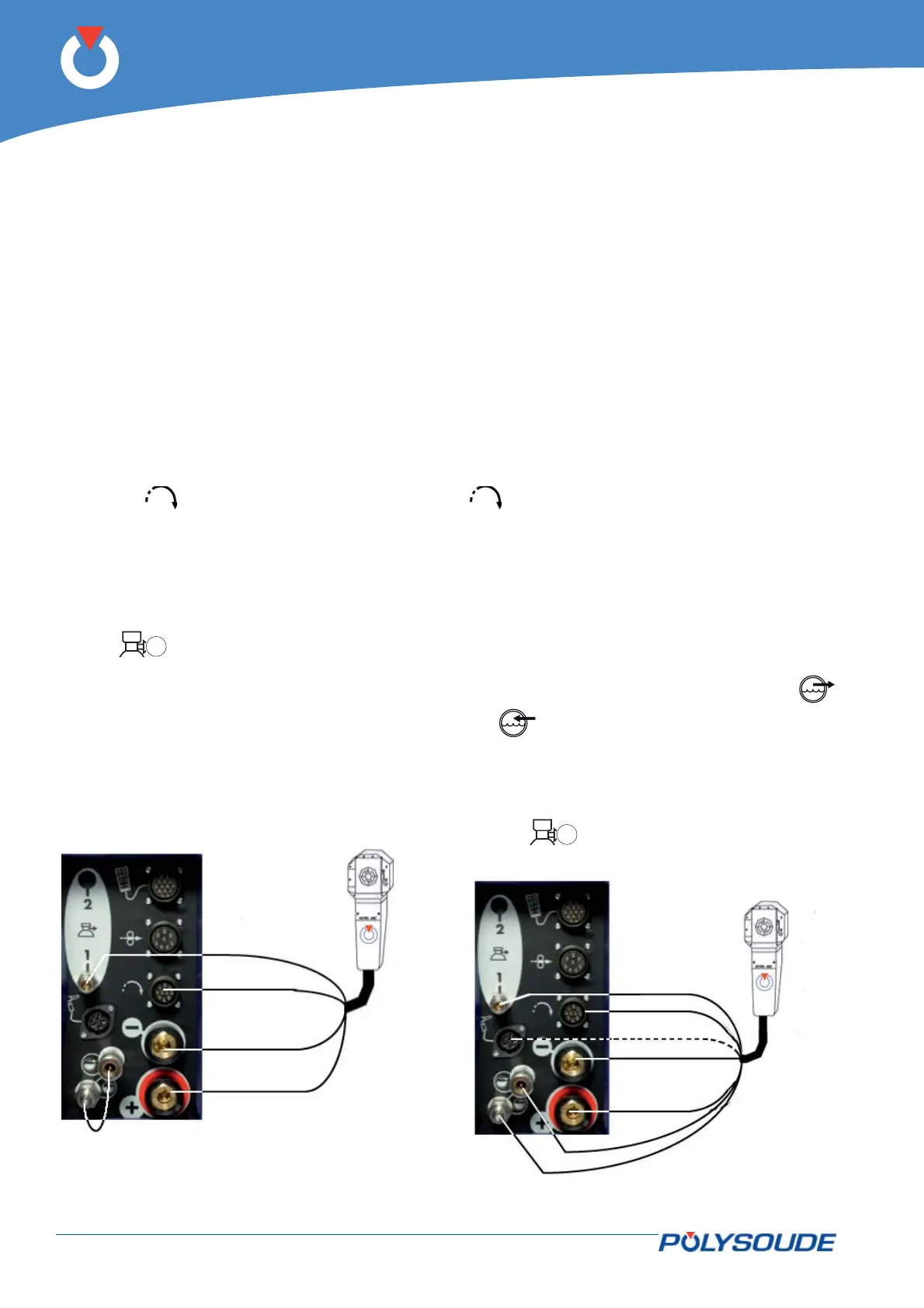

4. 3. 4. Connection of a liquid cooled closed chamber

welding head

This is the case for type K and MW Polysoude closed

welding heads.

◊ Connection of the electrode current cable

Connect the current cable on the "-" terminal with

the quick connector, locking it by a short rotation to

the right.

◊ Connection of the current return cable

Connect the current return conductor cable to the

"+" terminal with the quick connector, locking it by

a short rotation to the right. This cable is indicated

red.

◊ Connection of the rotation motor cable

Join the cable to the "Rotation" connector (symbol

). Make sure that the securing ring is tight oth-

erwise the system may not function correctly.

◊ Connection of the manual command cable

on the head (MW heads)

Connect the manual commands cable on the FA 5

terminal (Fig. 2.12) on the connection plate.

◊ Connection of the coolant circuit

Connection is made by 2 quick push type self sealing

couplings on the cooling unit RC 200 (symbols

and

).

◊ Connection of the torch shielding gas

Connection is made with a quick disconnect fi tting

situated at the connection panel of the PS 164-2

(symbol

1

).

Fig. 4.8 - Connection of an air cooled closed

chamber welding head

Fig. 4.9 - Connection of a liquid cooled closed

chamber welding head ( ---- for heads with

integrated commands)

Loading...

Loading...