62-92 PN-0908073 Rev. 11

PS 164-2

THE ART OF WELDING

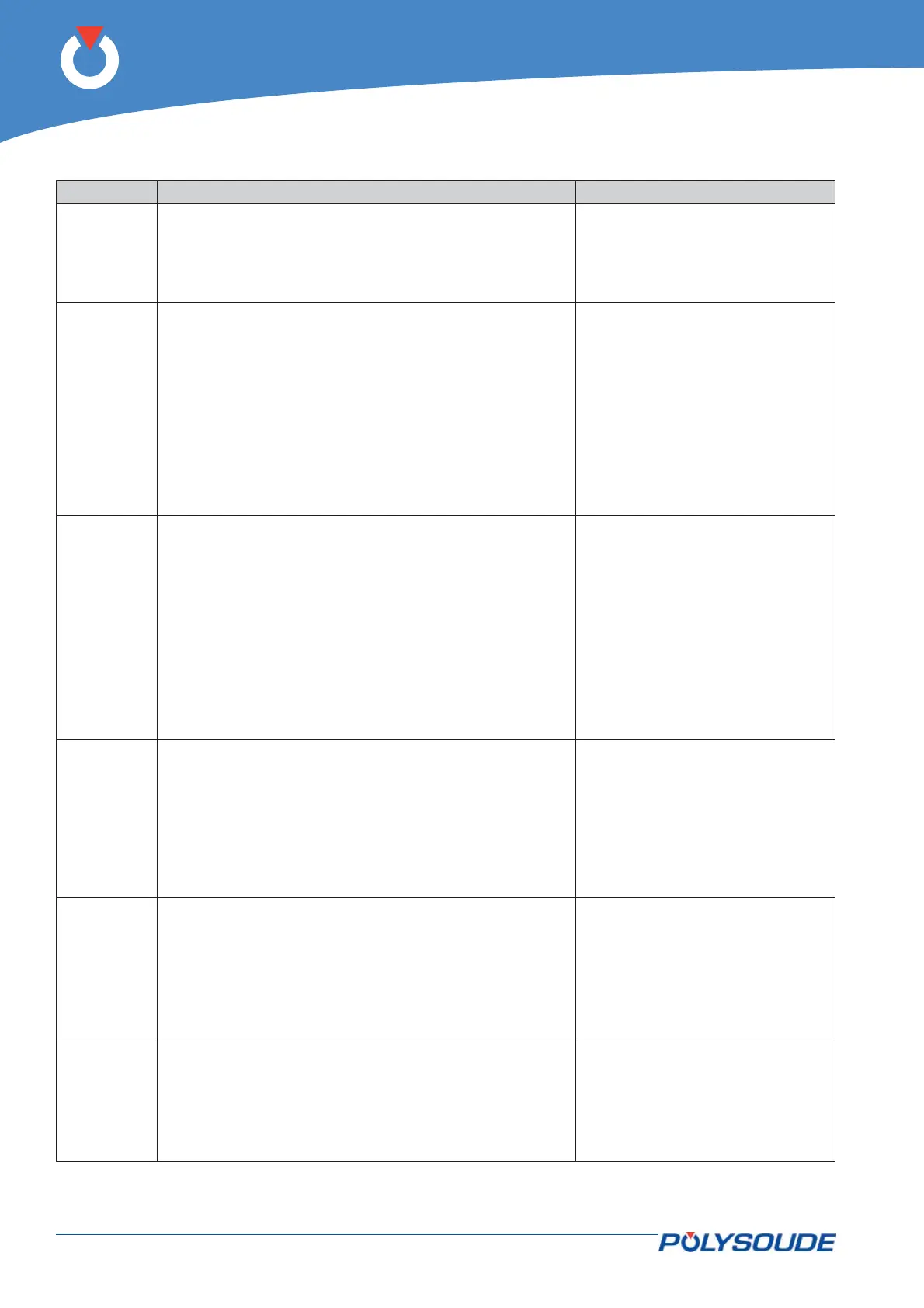

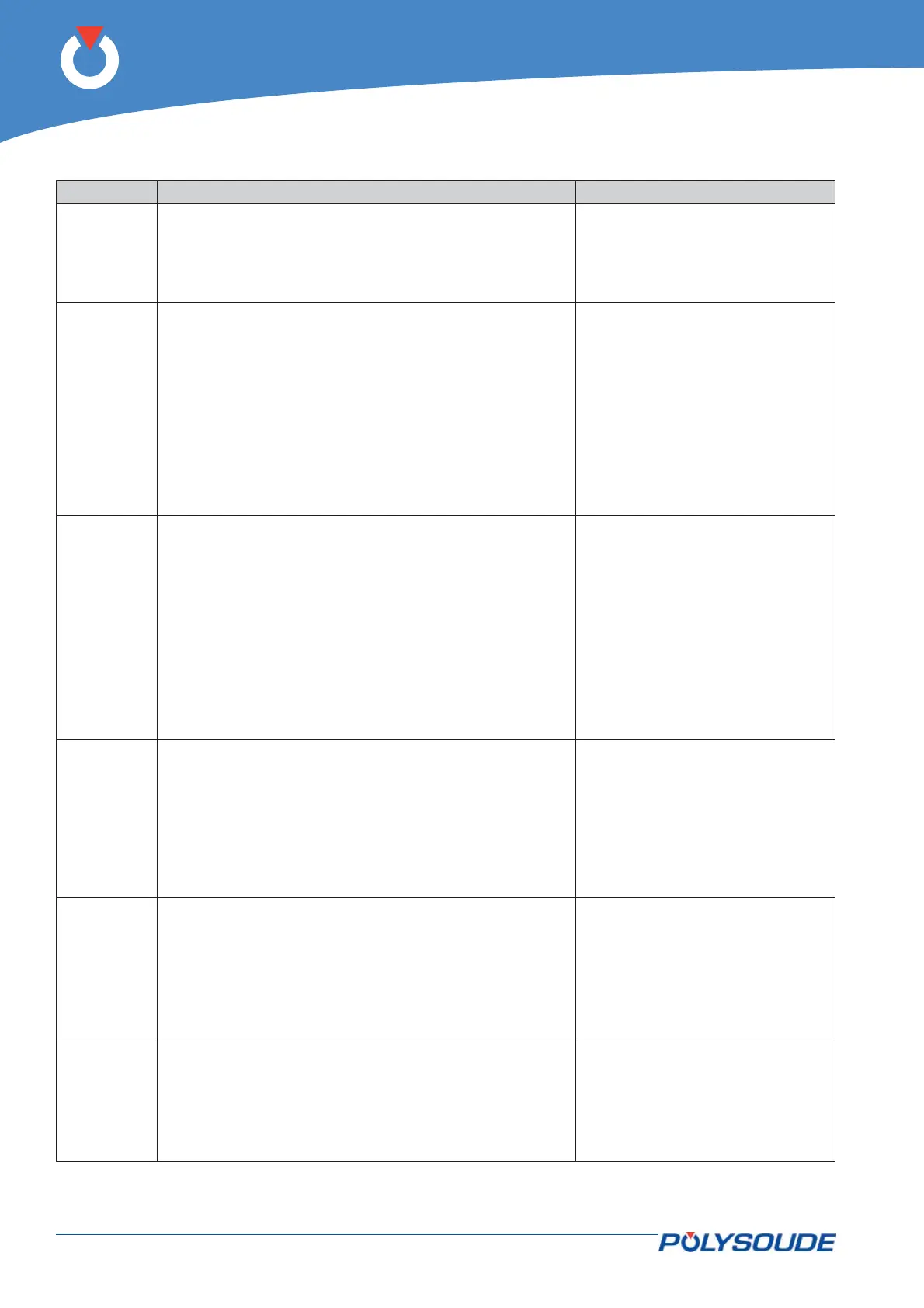

6. 5. 1. 2. Display of an error code

Error code Possible causes What to do

10 - Gas cylinder empty or gas valve is closed

- The quick coupling of the welding head is not correctly

connected

- Electric valve defect Check, change or open

- Check

- Have a skilled electrician to

check and replace, if neces-

sary

11 - Level of coolant liquid too low

- Cooling circuit dirty

- Coolant liquid circuit shunt not connected when using

an air-cooled head

- The quick couplings of the welding head are not pro-

perly connected

- Fuse defect

- Pump defect

- Silicon hose defect (MU welding head)

- Check and fi ll up

- Check, empty and clean the

circuit and the fi lter, fi ll up with

new cooling liquid

- Check and correct the connec-

tions (§ 4.3.3)

- Check and correct

- Check and change (§ 6.2.1)

- Have a skilled electrician to

check and replace, if necessary

- Replace

22 - Bad mains voltage

- Current cable improperly connected or damaged

- Ground connection placed on an improper place

- Electrode dirty or wrong distance electrode work piece

- Silicon hose defect (MU welding head)

- Ignition device not set up or incorrectly placed (MU, TP,

TS…welding heads)

- Unsuitable gas, gas output non adapted

- Power source out of order

- Power source defect (DC3.9 card)

- Check and correct

- Check or change

- Have the ground connection on a

right place (§ 2.3.2 or 2.3.6)

- See Operating manual of the

welding head for electrode set-

tings

- Replace

- Change the position

- Try with argon gas

- Call After Sales Service

- Call After Sales Service

23 - Tip of the electrode deteriorated or incorrectly groun-

ded

- Unsuitable distance electrode/work piece

- Ineffi cient gas protection

- Programmed welding current too low

- Ignition device placed too near from the torch (MU, TP,

TS … welding heads)

- See Operating manual of the

welding head for electrode set-

tings

- Correct

- Check the fl ow, the gas lens,

clean, correct

- Correct

-Move

24 - Electrode is in contact to the work piece

- Electrode is in contact to the fi ller wire

- Ignition device is in contact to the torch (MU, TP, TS …

welding heads)

- Bad insulation between wire guide support and torch

- Synoptic card 21700633 defect

- Power source defect

- Correct

- Change the position of the wire

inlet move

-Move

- Check and correct

- Replace

- Call After Sales Service

27 - Poor air circulation

- Maximum power of the source exceeded

- Fan defect

- Respect minimum distance of

openings to other objects (§

2.2.2), allow power source to

cool down

- Modify conditions of use

- Have a skilled electrician to

check and replace, if necessary

Loading...

Loading...