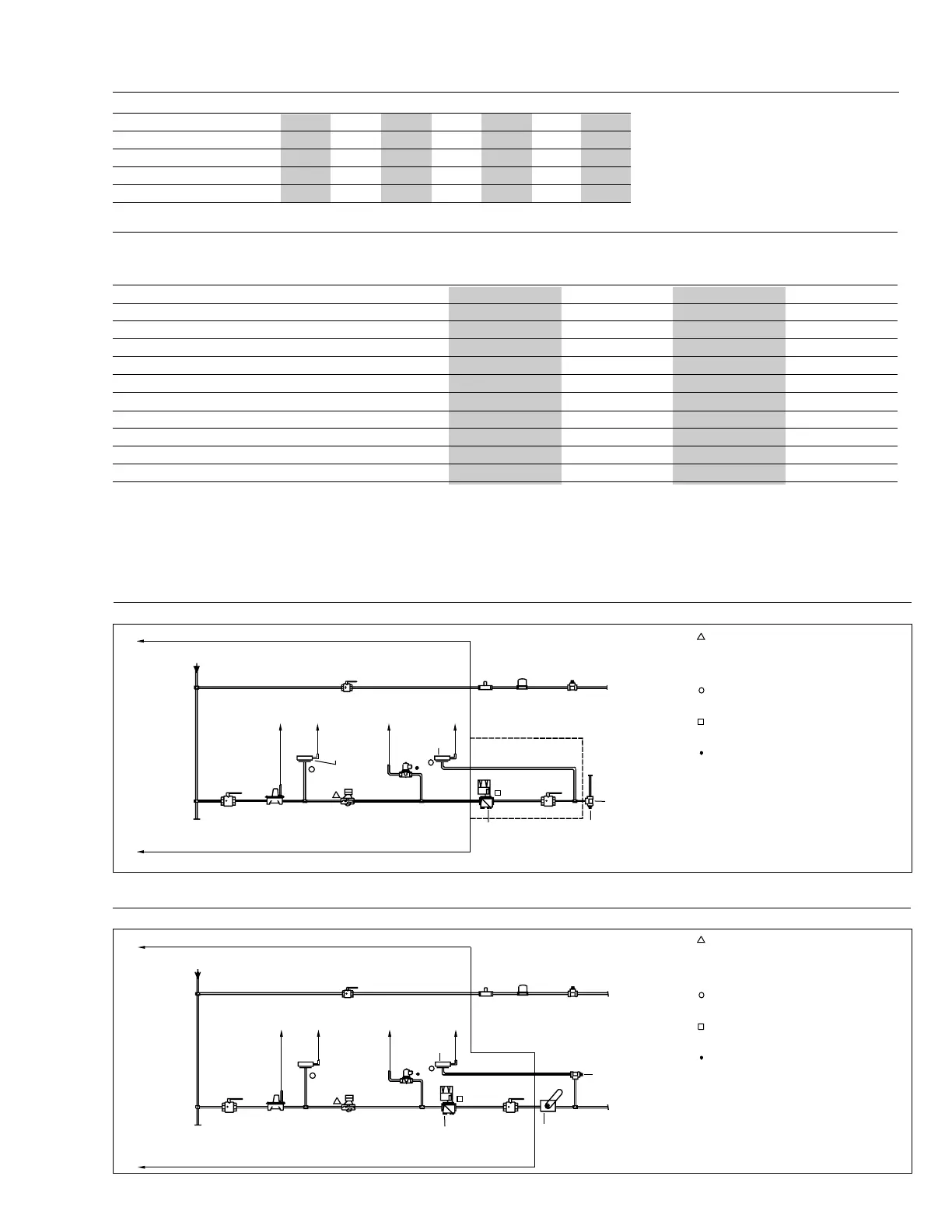

Field Piped

Gas Supply

Pilot

Shutoff

Cock

Vent to Atmosphere as Permitted by Code

Main Gas

Shutoff

Cock

Low Gas

Pressure

Switch

High Gas

Pressure

Switch

N.O.

Vent Valve

Dirt Leg with Cap

Extend to Floor

Main Gas

Pressure

Regulator*

Auxiliary

Gas Valve

Field Piped

Pilot

Solenoid

Valve

Pilot Gas

Pressure

Regulator

Gas Pilot

Ignitor

Gas Burner

Manifold

Leakage

Test Cock

Orifice Tee

Main

Gas Valve*

(With Pressure Tap; May

be in Nipple or Test Cock)

May be omitted on U.L. listed

units not exceeding 5,000 MBH

when proof of closure system is

furnished.

Denotes not required below

2,500 MBH.

Proof of closure feature

required above 5,000 MBH.

N.O. vent valve required above

12,500 MBH.

All On-Off units completely field

piped.

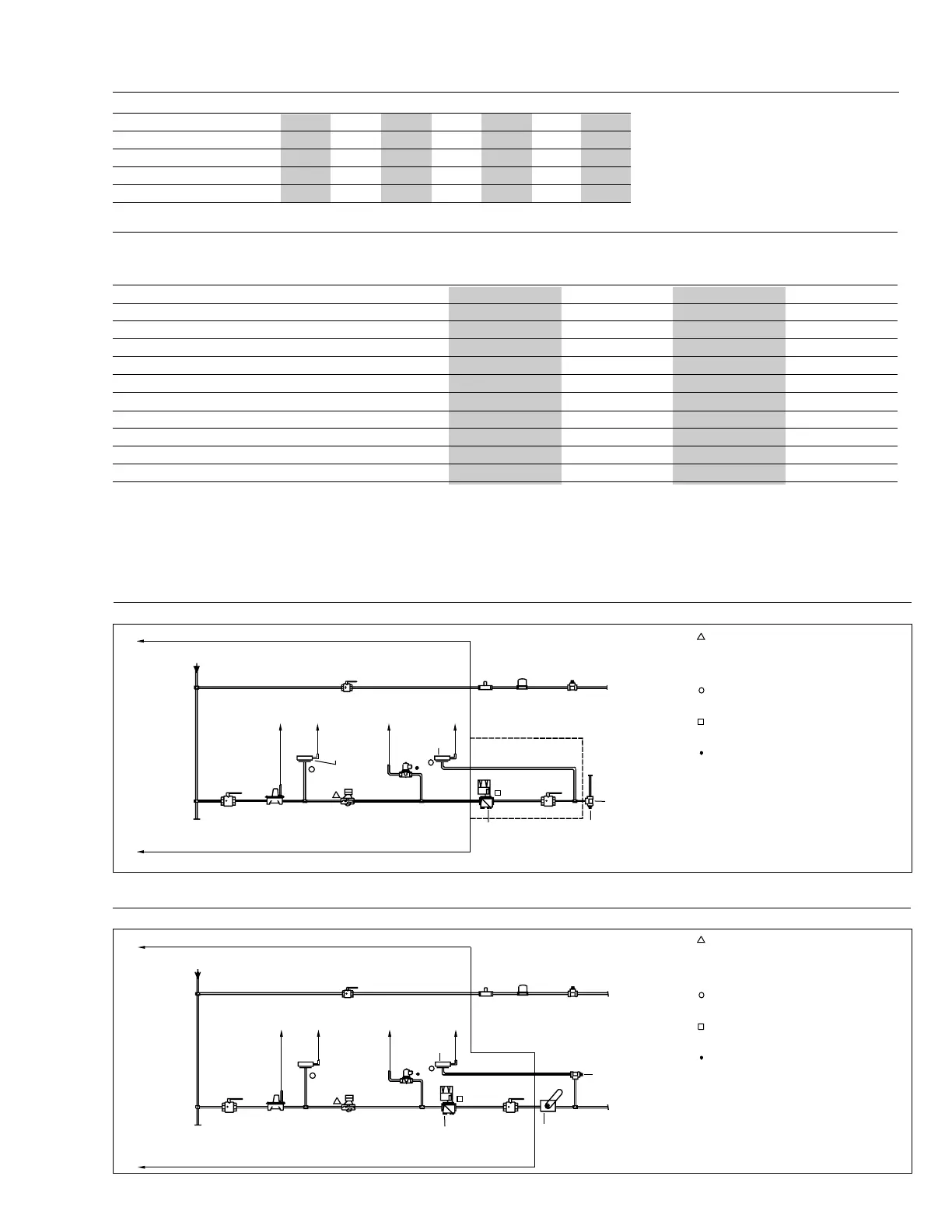

Field Piped

Gas Supply

Pilot

Shutoff

Cock

Vent to Atmosphere as Permitted by Code

Main Gas

Shutoff

Cock

Low Gas

Pressure

Switch

High Gas

Pressure

Switch

N.O.

Vent Valve

Dirt Leg with Cap

Extend to Floor

Main Gas

Pressure

Regulator*

Auxiliary

Gas Valve

Field Piped

Pilot

Solenoid

Valve

Pilot Gas

Pressure

Regulator

1

/

8

”

Pressure

Tap

Gas Pilot

Ignitor

Gas Burner

Manifold

Leakage

Test Cock

1

/

4

” Pressure Tap

Main

Gas Valve*

(With Pressure Tap; May

be in Nipple or Test Cock)

May be omitted on U.L. listed

units not exceeding 5,000 MBH

when proof of closure system is

furnished.

Denotes not required below

2,500 MBH.

Proof of closure feature

required above 5,000 MBH.

N.O. vent valve required above

12,500 MBH.

Butterfly Valve

(Operated by

Modulating Motor)

1

/

8

”

Pressure

Tap

1

/

4

” Pressure Tap

Figure 9

Typical Schematic Gas Piping for Type C Burner, Modulating System

Figure 8

Typical Schematic Gas Piping for Type C Burner, On-Off, Low-High-Off and Low-High-Low System

**

**

Table 4

Equivalent Length of Fittings in Feet

1. Supplied as standard on inputs of 2,500,000 BTU/hr. and

above. Available as an option below 2,500,000 BTU/hr. inputs.

2. Supplied as standard on inputs of 5,000,000 BTU/hr. and

above. Available as an option below 5,000,000 BTU/hr. inputs.

* Certain burners will have a combination pressure regulator/

diaphragm gas valve in lieu of a separate regulator and valve.

Canadian electrical and fuel codes require systems that

vary from the above. Consult the factory for specific details.

Table 5

Gas Train Components Supplied for Standard U.L. Burner Requirements

Fuel Air Control Modes of Operation On/Off Low/High/Off Low/High/Low Modulating

Main Gas Cock XU XU XU XU

Main Gas Pressure Regulator XU* XU XU XU

High and Low Gas Pressure Switches OU X

1

UX

1

UX

1

U

Automatic Main Gas Valve XU* X X XU

Automatic Main Gas Valve with Proof of Closure OX

1

X

1

X

1

Main Auxilary Gas Valve OX

2

X

2

X

2

Leak Test Gas Cock XU X X XU

Pilot Cock, Pressure Regulator & Solenoid Valve XXX X

Modulating Butterfly Valve N/A N/A N/A X

Side Tee Orifice Assembly X X X N/A

Main and/or Pilot Gas Pressure Gauge OOO O

See Gas Flow Schematics this page, Figure 8 and 9 for additional information

X - Supplied as standard O - Optional N/A - Not available (U) - Unmounted

* On some burner models at inputs below 2500 MBH a combination pressure regulator/automatic gas valve may be used in place of the separate main gas

pressure regulator and main gas shutoff valve shown in Figure 8 and 9 above. For specifics on your burner refer to the gas piping diagram supplied with the

burner.

Pipe Size (IPS) 1 1.25 1.5 2 2.5 3 4

Std. Tee through Side 5.5 7.5 9.0 12.0 14.0 17.0 22.0

Std. E11 2.7 3.7 4.3 5.5 6.5 8.0 12.0

45

o

E11 1.2 1.6 2.0 2.5 3.0 3.7 5.0

Plug Cock 3.0 4.0 5.5 7.5 9.0 12.0 16.0

C10

Rev.304

Loading...

Loading...