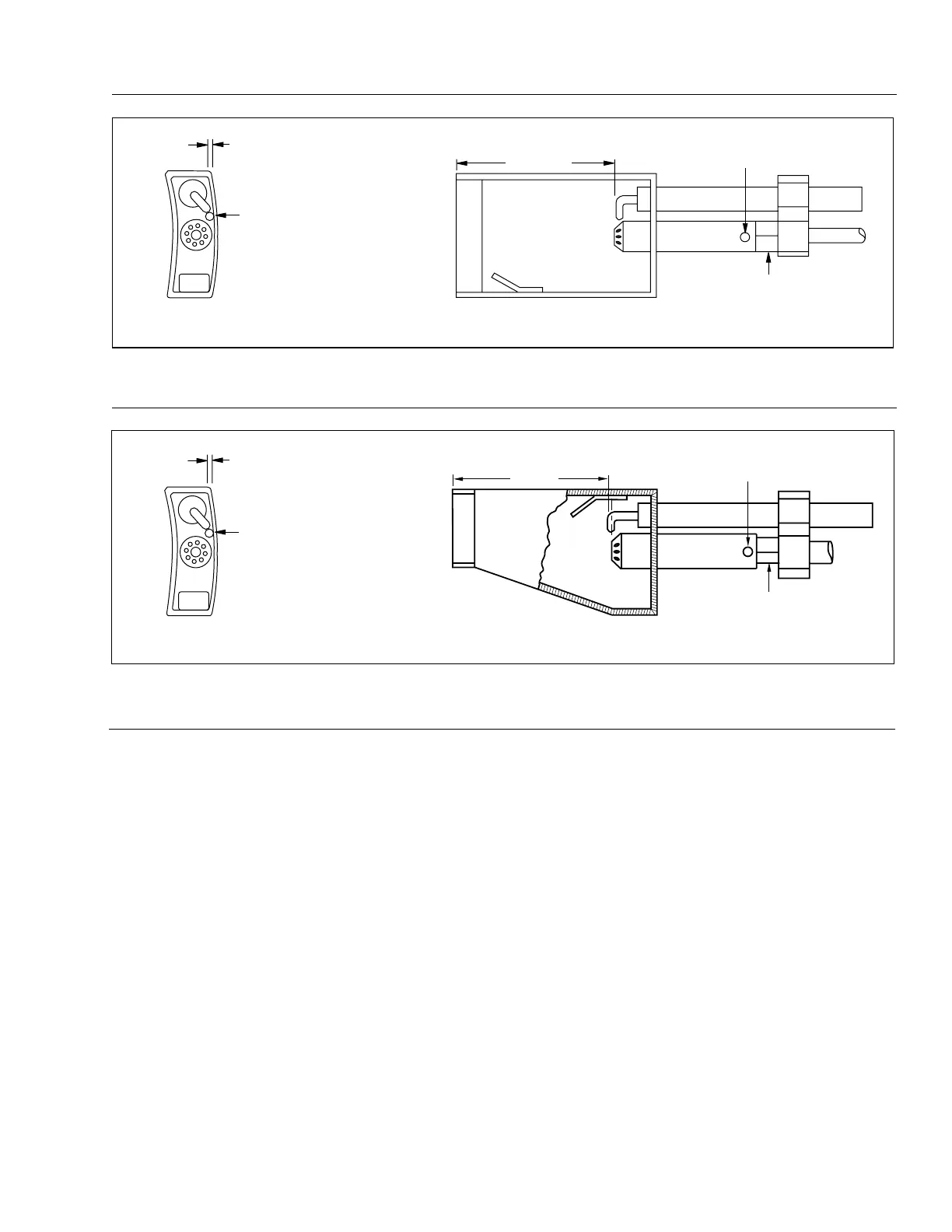

Figure 40

C1 & C2 Ignition Electrode Adjustment

Gas Pilot Flood Test

Many pilot problems are caused by a poor mixture of

gas and air at the point of ignition (ignition spark gap).

The cause of this poor mixture condition is usually

excessive gas flow or insufficient air (air dampers

are closed too far).

Once the pilot is adjusted and felt to be correct - it is

suggested that the following test be accomplished to

further verify that the pilot will be reliable.

1. Turn the burner off and shut the manual leak test

cock in the main gas train. (This valve should always

be closed when making pilot adjustments.)

2. If the burner is Low/High/Off, Low/High/Low or

Modulating, take steps to keep the fuel air linkage in

the pilot light off position. If the flame safeguard

control has a timer check switch, it can be placed in

the test position. If the flame safeguard control does

not have the timer switch, it may be necessary to

disconnect the power wire to the motorized gas

valve.

3. Install a 0 to 10" W.C. gas pressure gauge or a

manometer in the pilot test tee fitting. Plug an

appropriate flame signal meter into the flame

safeguard control.

4. Disconnect the high tension ignition leadwire at the

ignition transformer secondary terminal. Either hold

onto the insulated portion or let the free ignition wire

hang loose, so that it is not able to come into contact

with the bare ignition terminal on the transformer.

5. Start the burner and let it go through the prepurge

period. As soon as the pilot ignition circuit is

energized (listen for the sound of the solenoid valve

opening or watch the pilot gas pressure gauge), let

about 3 to 4 seconds lapse and then CAREFULLY

(the ignition transformer is putting out 6000 volts)

touch the ignition leadwire to the transformer terminal

secondary.

If the pilot fuel/air mixture and ignition electrode are

adjusted correctly, the pilot will light instantly and

the flame signal reading will be steady and of the

correct value. If the pilot does not light instantly,

then readjust the pilot gas pressure and/or the air

dampers and/or the ignition electrode setting

according to the information provided in this

manual.

6. Turn the burner off. Reconnect the ignition leadwire

to the ignition transformer secondary terminal. Set

the check switch in the flame safeguard control for

automatic operation. Reconnect any wires that have

been disconnected to hold the motorized gas valve in

the pilot position. Open the checking gas cock, turn

the burner on and verify that the pilot lights and

proves instantly, providing good, smooth ignition of

the main gas flame.

7. If Gas Pilot Flood Test is successful, it is not

always a guarantee of correct pilot air/fuel mixture,

but a failure will almost always indicate an

excessively rich mixture.

1

/

16

” -

3

/

32

”

Spark Gap between Electrode

Tip and Pilot Case (Housing)

Air Hole

Primary Air Holes (2)

Pilot Orifice

3

1

/

16

”

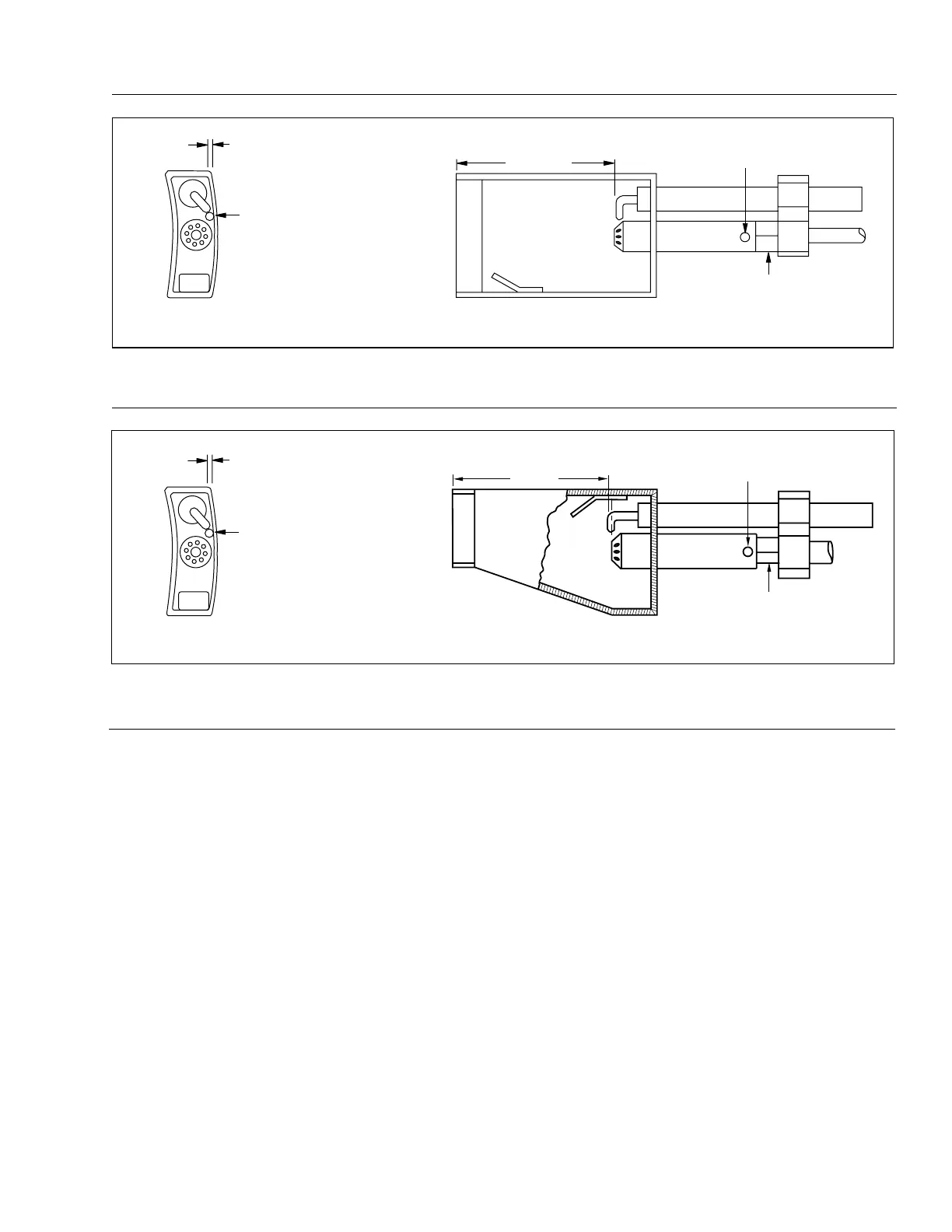

Figure 41

C3, C4 & C5 Ignition Electrode Adjustment

For C5B, C6, C7 and C8 Pilot Ignition Electrode Adjustment, see Figure 37, page 37.

1

/

16

” -

3

/

32

”

Spark Gap between Electrode

Tip and Pilot Case (Housing)

Air Hole

2

15

/

16

”

Primary Air Holes (2)

Pilot Orifice

C40

Rev.304

Loading...

Loading...