1

5 6

2

3

7

84

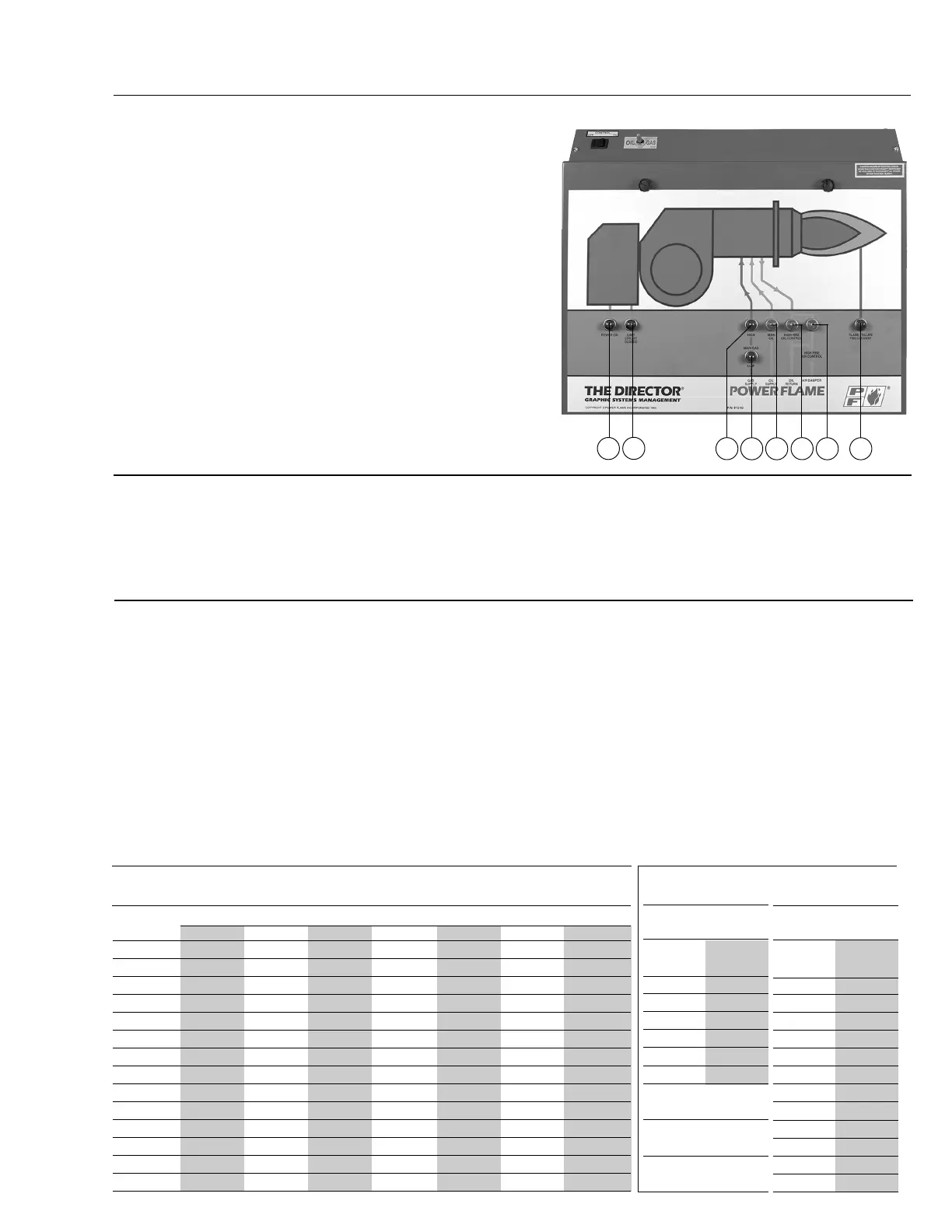

Table 3A

Correction Factors

Table 3

Capacity of Pipe - Natural Gas (CFH)

With Pressure Drop of 0.3” w.c. and Specific Gravity of 0.60

Pipe Length Pipe Size - Inches (IPS)

In Feet

11

1

/

4

1

1

/

2

22

1

/

2

34

10 520 1050 1600 3050 4800 8500 17500

20 350 730 1100 2100 3300 5900 12000

30 285 590 890 1650 2700 4700 9700

40 245 500 760 1450 2300 4100 8300

50 215 440 670 1270 2000 3600 7400

60 195 400 610 1150 1850 3250 6800

70 180 370 560 1050 1700 3000 6200

80 170 350 530 990 1600 2800 5800

90 160 320 490 930 1500 2600 5400

100 150 305 460 870 1400 2500 5100

125 130 275 410 780 1250 2200 4500

150 120 250 380 710 1130 2000 4100

175 110 225 350 650 1050 1850 3800

200 100 210 320 610 980 1700 3500

Note: Use multiplier at right for other specific gravities and pressure drops.

Specific Gravity

Other Than 0.60

Specific Multiplier

Gravity

0.50 1.10

0.60 1.00

0.70 0.926

0.80 0.867

0.90 0.817

1.00 0.775

Propane - Air

1.10 0.740

Propane

1.55 0.662

Butane

2.00 0.547

Specific Drop

Than 0.3

Pressure Multiplier

Drop

0.1 0.577

0.2 0.815

0.3 1.00

0.4 1.16

0.6 1.42

0.8 1.64

1.0 1.83

2.0 2.58

3.0 3.16

4.0 3.65

6.0 4.47

8.0 5.15

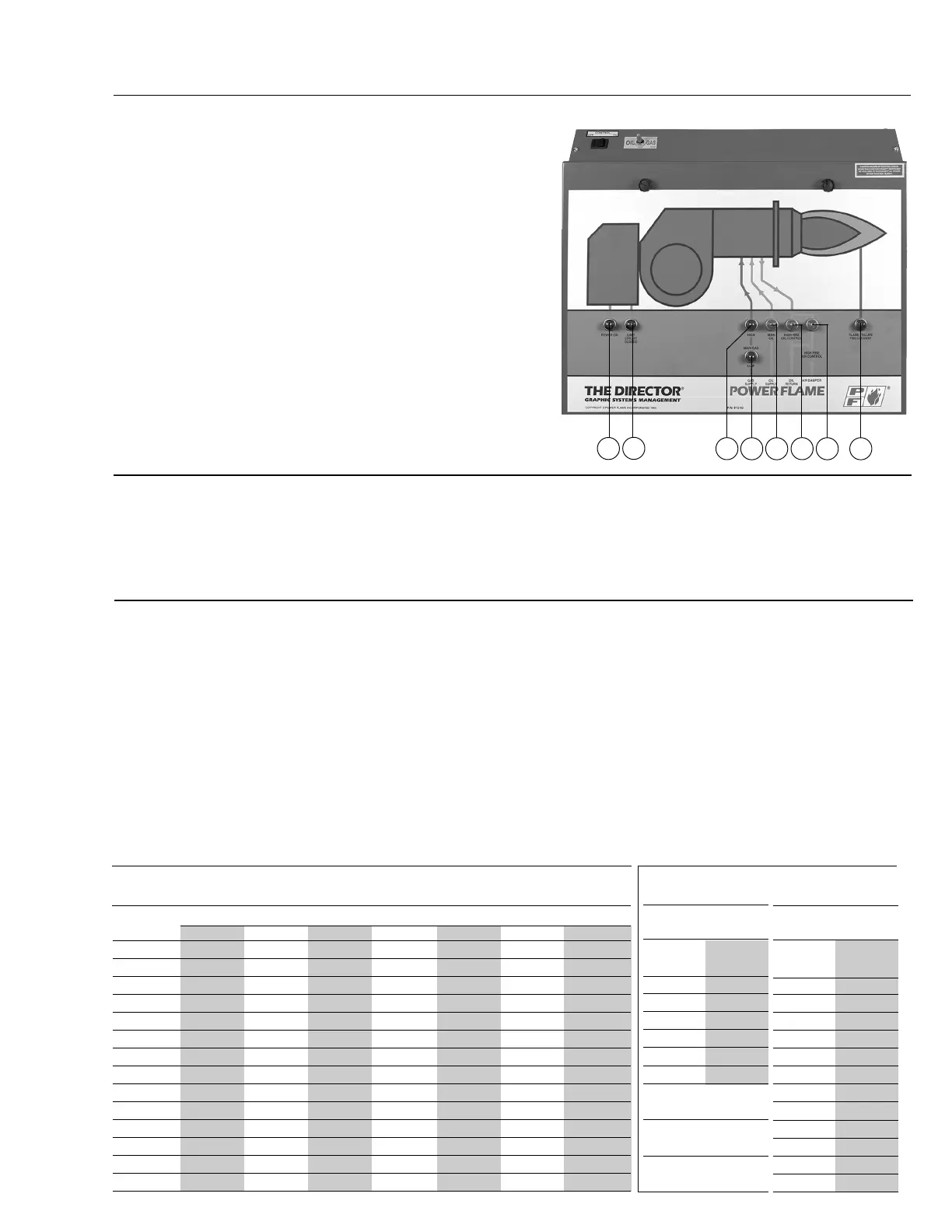

Figure 7

The Director

®

Annunciation System

The Director

®

Annunciation System Mounted on

removable Total Access front panel door, complete with

quick disconnect electrical connection. The Director can

be removed from the panel box (see above) and kept in

operating mode by using the extended length umbilical

cord between the Director and panel box connections.

Annunciation Legend for Gas/Oil Burner with Low-High-

Low Operating Mode

1. Power On

2. Limit Circuit Closed

3. Flame Failure (Flame Safeguard Lockout)

4. Main Gas Valve - Low Position

5. Main Gas Valve - High Position

6. Main Oil Valve

7. High Fire Oil System

8. High Fire Air System

INSTALLATION

The installer should contact the local gas utility relative

to available supply pressures, limitations on allowable

pressures in the building, general piping requirements

and applicable codes, restrictions and regulations.

Considerations of these types, as well as written

permits and other state, city and local codes, should be

discussed with and approved by the appropriate

governing bodies.

GAS SUPPLY PIPING

Gas piping should be sized to provide required pressure

at the burner train inlet manual shutoff cock, when

operating at the maximum desired fuel input.

All gas piping should be appropriately pressure tested to

ensure leak free operation. It is recommended that a dirt

pocket or trap be piped into the gas supply system just

ahead of the burner train inlet manual shutoff cock.

When testing with pressures higher than the maximum

pressure ratings of the gas train components, be sure to

isolate these components and test their piping for gas

leaks with correct pressures only. On some burners, the

maximum main gas train and/or pilot gas train compo-

nents pressure is

1

/2 psig. (14" W.C.).

Refer to Table 3 for information relating to the sizing of

gas supply piping. These charts are based on the

general flow characteristics of commercially produced

black wrought iron pipe. If in doubt regarding flow

capabilities of a chosen line size, the next largest size

is recommended.

Refer to page 10, Figures 8 and 9 for typical gas piping

schematics to meet U.L. requirements in the C burner

firing ranges.

C9

Rev.304

Loading...

Loading...