facturer’s bulletin shipped with the burner. It is also stron-

gly suggested that all test procedures outlined in the flame

safeguard control manufacturer’s bulletin be conducted.

37. Complete the Burner Start Up Information and

TestData sheets on pages 46 and 47.

7. SERVICING AND COMPONENT ADJUSTMENTS

General Information on Internal Bypass Oil Nozzle Systems

1. The system is designed to use 300 PSI pressure at the

nozzle inlet at low and high fire (and throughout the

range on modulating systems). The firing rate is changed

by an adjustable bypass arrangement that allows more

or less oil to bypass the nozzle and flow to the return line.

Low fire pressures at the bypass pressure test tee will

generally be from 60 to 100 PSI, with high fire bypass

pressures from 180 to 225 PSI. These pressures will vary

depending upon the nozzle size selection and specific

job firing conditions. See this page, Table 8 for flow rates,

sizing and pressure information.

2. Smoky fires with apparent large droplet size in the spray

pattern are generally caused by low nozzle or return flow

pressures. To properly check the system, it is necessary

to verify both nozzle supply and return pressures. Also

check to make certain that the nozzle adapter and

strainer are not partially plugged.

3. Careless cleaning or handling of the nozzle may

damage the orifice, causing heavy streaks in the oil

spray. This will also show up as large droplets or sparks

in the flame.

4. Off center fires, low bypass line pressures and safety

lockouts (due to poor spray pattern and ignition failure)

may result from plugged slots in the nozzle distributor

head. When such situations are observed, the

nozzle should be removed, disassembled and

cleaned.

5. Excessive after squirt of oil is caused by air in the

system. Be sure air is not trapped in pressure

gauges, overhead oil lines or fittings. A leaking

check valve on the bypass return line from the

nozzle can create the same effect.

6. The Teflon seal should stay on the nozzle when

servicing. On some sizes of burners using Delavan

30630 and 30637 Series nozzles, the Teflon seal

stays in the nozzle adapter. If it is damaged

through careless handling, the resulting leak will

cause an increase in the burning rate, when the

bypass line is closed at high fire.

7. High turn down ratios are a distinct advantage of

internal bypass systems. It is possible, however,

to adjust for a low fire so small that the flame is

being chilled. The fire will look excellent and

appear bright and uniform, but a combustion

efficiency test will reveal high smoke content and

low CO

2

. To correct this situation, increase the oil

flow or decrease the air, or both. Be sure to test

with proper instruments to ensure good, clean

efficient combustion throughout the firing range.

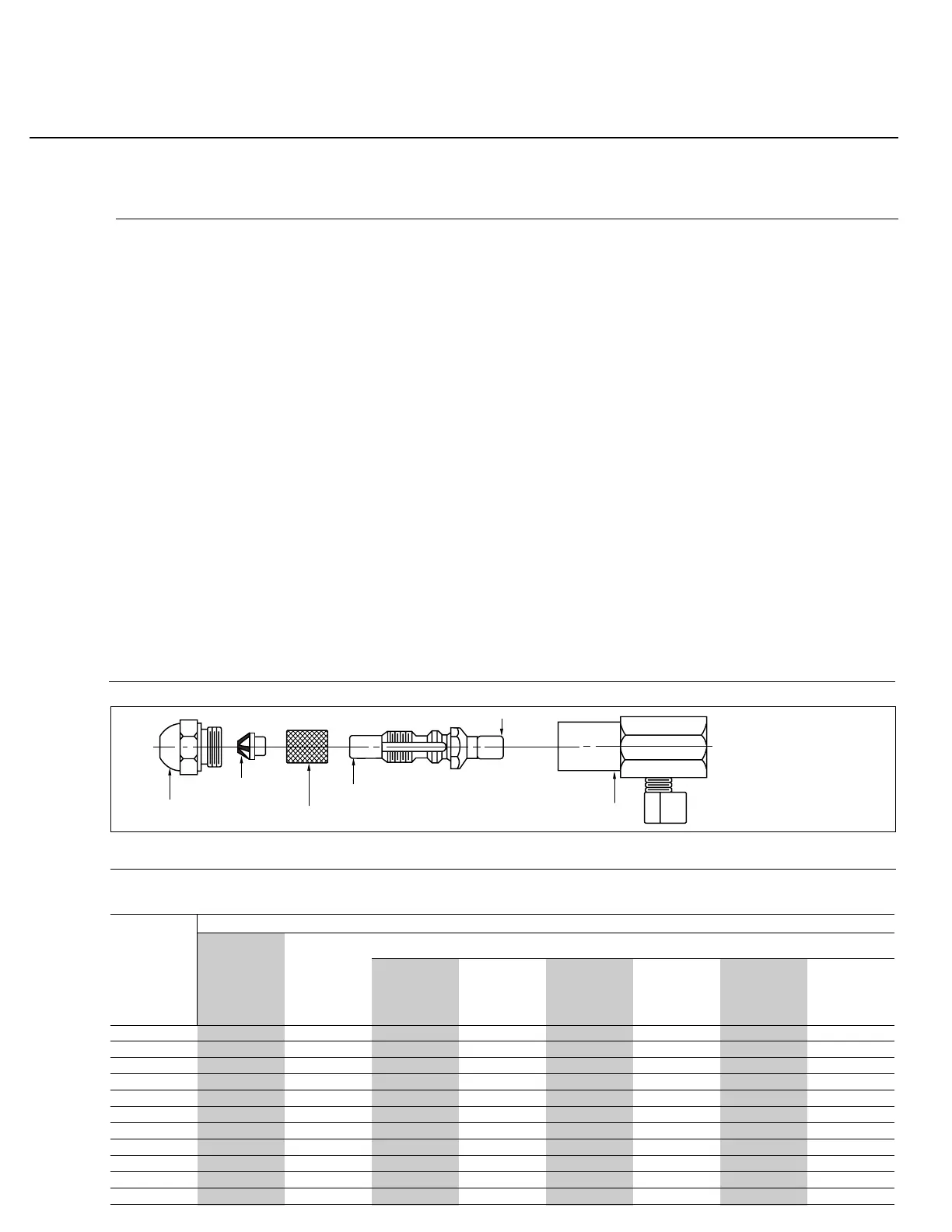

HAGO

Nozzle Size

100 PSIG

Nominal

Rating GPH

#2 Fuel Oil

By-Pass

(Return)

Closed

Approx. High

Fire Rate

GPH

300 PSIG

By-Pass

(Return)

Closed

Approx. High

Fire By-Pass

(Return)

Pressure

PSIG By-Pass

(Return)

Closed

Approx.

By-Pass

(Return)

Pressure

PSIG

Approx.

Firing Rate

GPH

Approx.

By-Pass

(Return)

Pressure

PSIG

Approx.

Firing Rate

GPH

Approx.

By-Pass

(Return)

Pressure

PSIG

Approx.

Firing Rate

GPH

Supply Pressure to Nozzle 300 PSIG at All Rates*

Reduced Firing Rates

4.5 7.3 207 180 5.5 150 4.4 120 3.1

5.0 8.5 196 150 5.9 120 4.4 90 2.8

5.5 9.0 209 180 7.0 150 5.2 120 3.8

6.0 10.2 190 150 7.0 120 5.1 90 3.1

6.5 10.8 195 150 7.6 120 5.2 90 3.4

7.0 11.5 202 150 7.1 120 5.1 90 3.5

7.5 12.6 181 150 10.0 120 7.1 90 4.8

8.0 13.3 197 180 11.6 150 8.2 120 5.5

9.0 15.2 200 180 12.5 150 8.9 120 6.0

9.5 15.9 178 150 12.0 120 8.0 90 5.1

10.0 17.2 202 180 13.8 150 9.6 120 6.3

Table 8

Internal Bypass (Return Flow) Nozzle Data

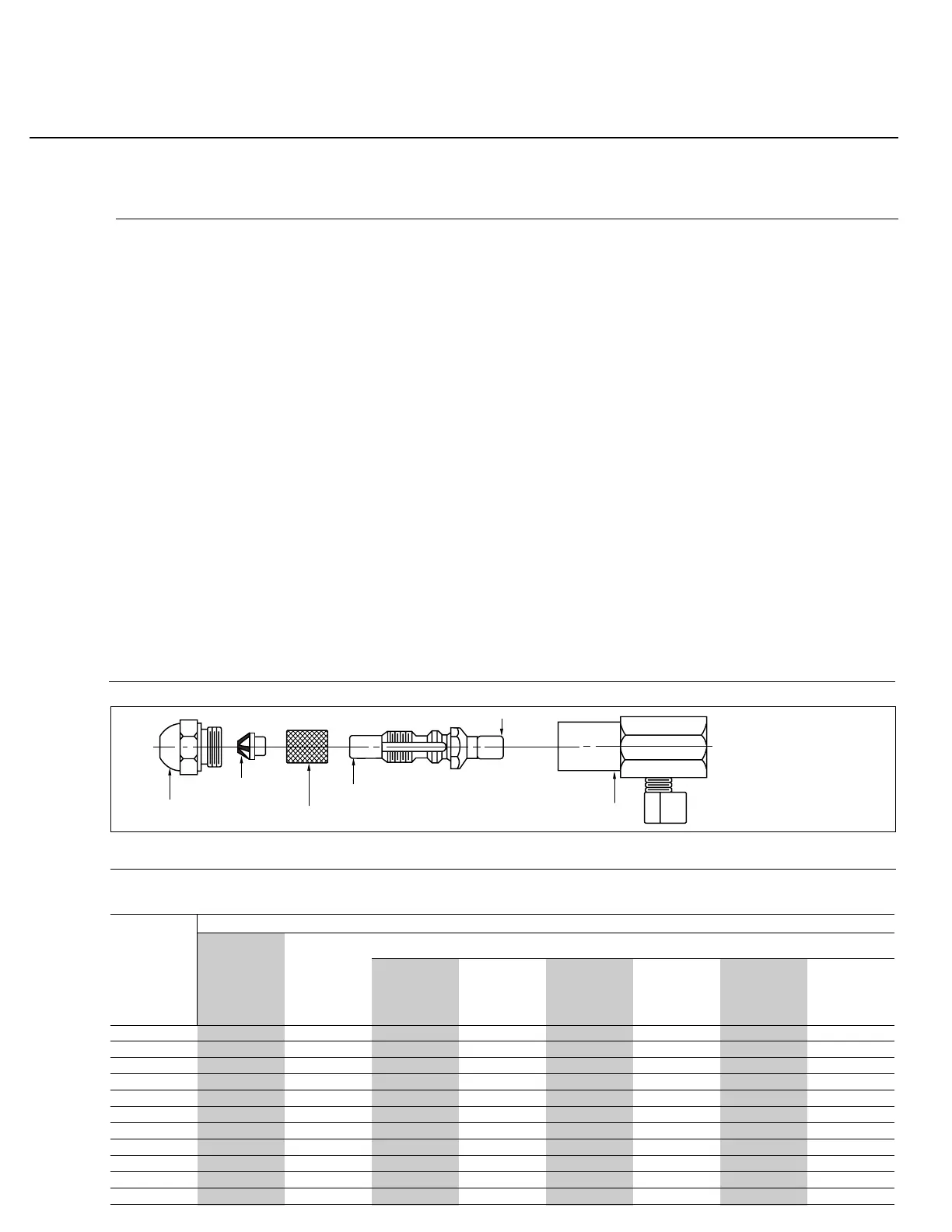

Figure 29

Internal Bypass Oil Nozzle Components

Nozzle Tip

Distributor

Strainer

Combination Locknut & Strainer Support

Seal Bushing

Adapter

C31

Rev.304

Loading...

Loading...