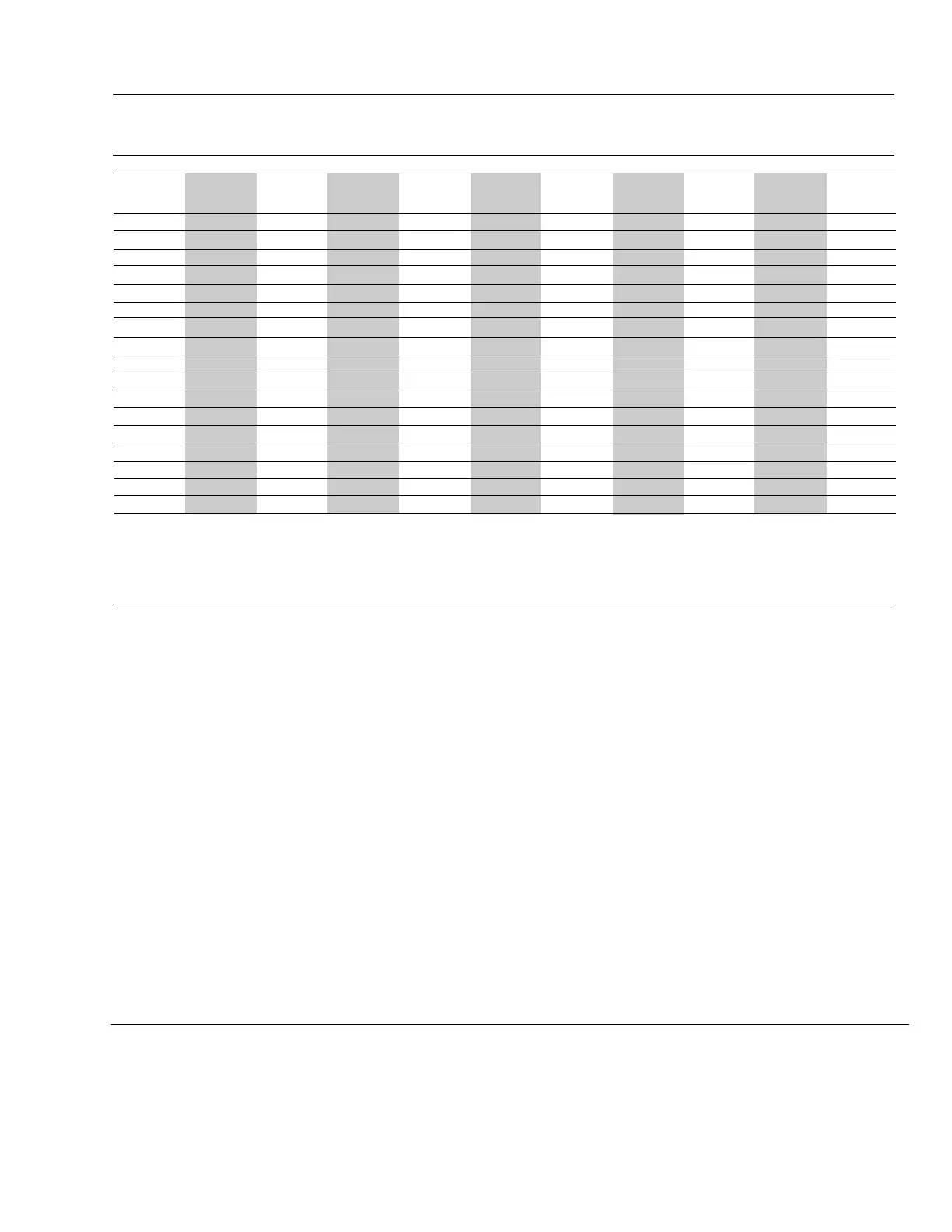

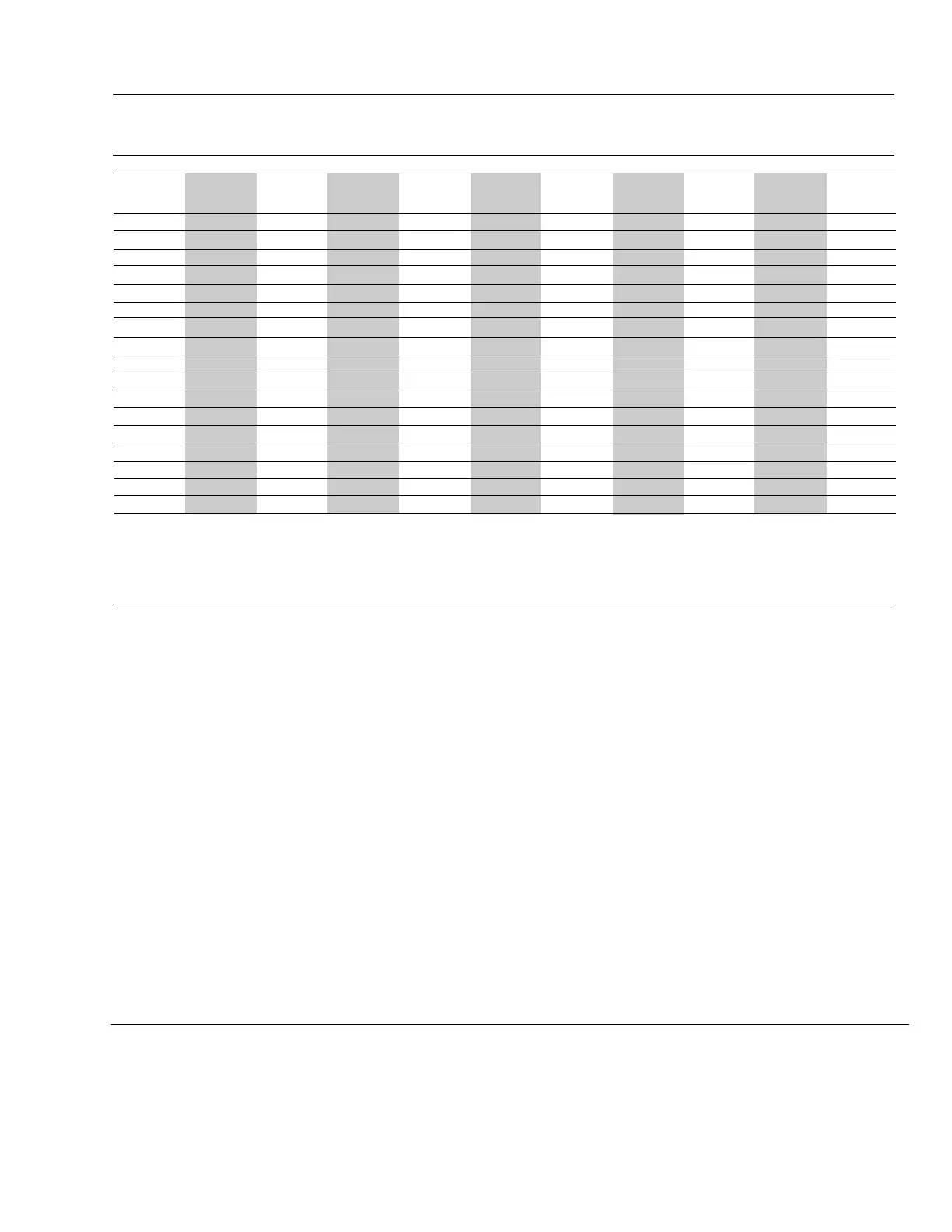

Table 9

OIL NOZZLE FLOW RATES

Simplex Nozzle System (Monarch PLP or Equivalent Solid or Semi Solid)

Flow Rate vs Pressure

Oil Nozzle Servicing

1. Nozzles used on Power Flame Type C burners are of two

types: simplex and internal bypass. The simplex nozzle

is normally used on smaller burners in the three to eight

gallons per hour range. The bypass nozzle is used for

larger inputs requiring higher turndown or more

sophisticated air/fuel control. Both types of nozzles have

GPH ratings stamped on the side. Stamped ratings are

based on 100 psig except models 30630 and 30637

which are based on 300 psig. The burners operate in the

300 psig range. See pages 31 through 34, Tables 8 and

9 for flow rates, pressure and sizing information.

2. When removing or replacing the oil nozzle and electrode

assembly, take care to prevent damage to the ignition

wire.

3. The nozzles should be removed from the nozzle adapter

by use of the proper wrench. They should be disas-

sembled and thoroughly cleaned with a liquid solvent

(preferably non-flammable) and a brush.

4. Do not use a screwdriver, wire brush or similar metallic

objects to clean nozzles. Damage to orifices or spray

slots result in off-center or sparky fires.

5. The nozzle should be seated firmly in the nozzle

adapter to prevent leaks.

6. If a nozzle is damaged or burned, replace it.

7. The entire oil tube and nozzle assembly (the oil drawer

assembly) may be removed for ease of service.

8. When cleaning and taking the nozzle apart, do not

force it.

9. For additional information on bypass nozzles, see

page 31. Note that the Teflon seal in the Monarch

F80BPS and Delavan 33769 nozzles is an integral

part of the nozzles and that if the seal is removed

accidentally, the nozzle must be replaced. On the

Delavan 30630 and 30637 nozzles, the seal normally

remains in the nozzle adapter. When the nozzle is

removed from the adapter, the seal should also be

removed and replaced with a new seal.

Oil Pump or Oil Flow Problems and Typical Solutions

NO OIL DELIVERED

1. Reversed pump rotation

2. Suction lift too high (See page 12, Figure 10)

3. Air leak in suction line

4. Pump not primed, or has lost prime

5. Pump coupling not installed properly

6. Pump defective

7. Line plugged

8. Valve closed

NOISY PUMP

1. Air leak in suction line

2. Pump not securely mounted

3. Vibration caused by bent shaft or misalignment

4. Pump overloaded

5. Suction line vacuum so high that vapor forms

within the liquid (see page 12, Figure 10)

Capacity in GPH #2 Oil

100#

Nominal

Rating

2 2.1 2.3 2.4 2.6 2.7 2.9 3.0 3.1 3.2 3.3

2.5 2.6 2.8 3.0 3.2 3.4 3.6 3.7 3.8 4.0 4.1

3 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.7 4.8 5.0

3.5 3.7 3.9 4.2 4.5 4.7 4.9 4.2 5.4 5.8 5.9

4 4.2 4.5 4.8 5.1 5.4 5.6 5.9 6.2 6.4 6.7

4.5 4.7 5.0 5.4 5.7 6.1 6.3 6.6 7.0 7.2 7.4

5 5.3 5.6 6.0 6.4 6.8 7.1 7.3 7.7 7.9 8.2

5.5 5.7 6.1 6.5 7.0 7.3 7.7 8.0 8.4 8.6 9.1

6 6.3 6.7 7.2 7.7 8.1 8.5 8.8 9.2 9.5 9.9

6.5 6.8 7.2 7.9 8.3 8.8 9.2 9.5 10.0 10.3 10.7

7 7.3 7.9 8.3 9.0 9.4 9.9 10.3 10.7 11.2 11.4

7.5 7.8 8.5 8.9 9.6 10.0 10.5 11.0 11.5 11.9 12.2

8 8.3 9.1 9.5 10.3 10.8 11.3 11.8 12.3 12.8 13.0

9 9.4 10.1 10.8 11.5 12.0 12.8 13.2 13.9 14.4 14.8

10 10.4 11.2 12.0 12.8 13.4 14.2 14.7 15.4 16.0 16.6

11 11.5 12.5 13.3 14.2 15.0 15.6 16.2 17.0 17.7 18.2

12 12.5 13.6 14.5 15.3 16.2 17.0 17.7 18.5 19.2 19.8

120# 140# 160# 180# 200# 220# 240# 260# 280# 300#

C34

Rev.304

Loading...

Loading...