C11

Rev.304

1. The standard pump normally supplied is 19 GPH for On-Off

or Modulating and 40 GPH for fixed air low fire start,

Low-High-Off and Low-High-Low operation. Optional

pumps are available which, depending on model specified,

could be as high as 70 GPH. Refer to information shipped

with the burner and/or consult the factory for specifics.

2. The standard pump normally supplied is 40 GPH for Low-

High-Off and Low-High-Low and 70 GPH for On-Off and

Modulating operation. Optional pumps are available for

Low-High-Off and Low-High-Low which could be as high

as 70 GPH. Refer to information shipped with the burner

and/or consult the factory for specifics.

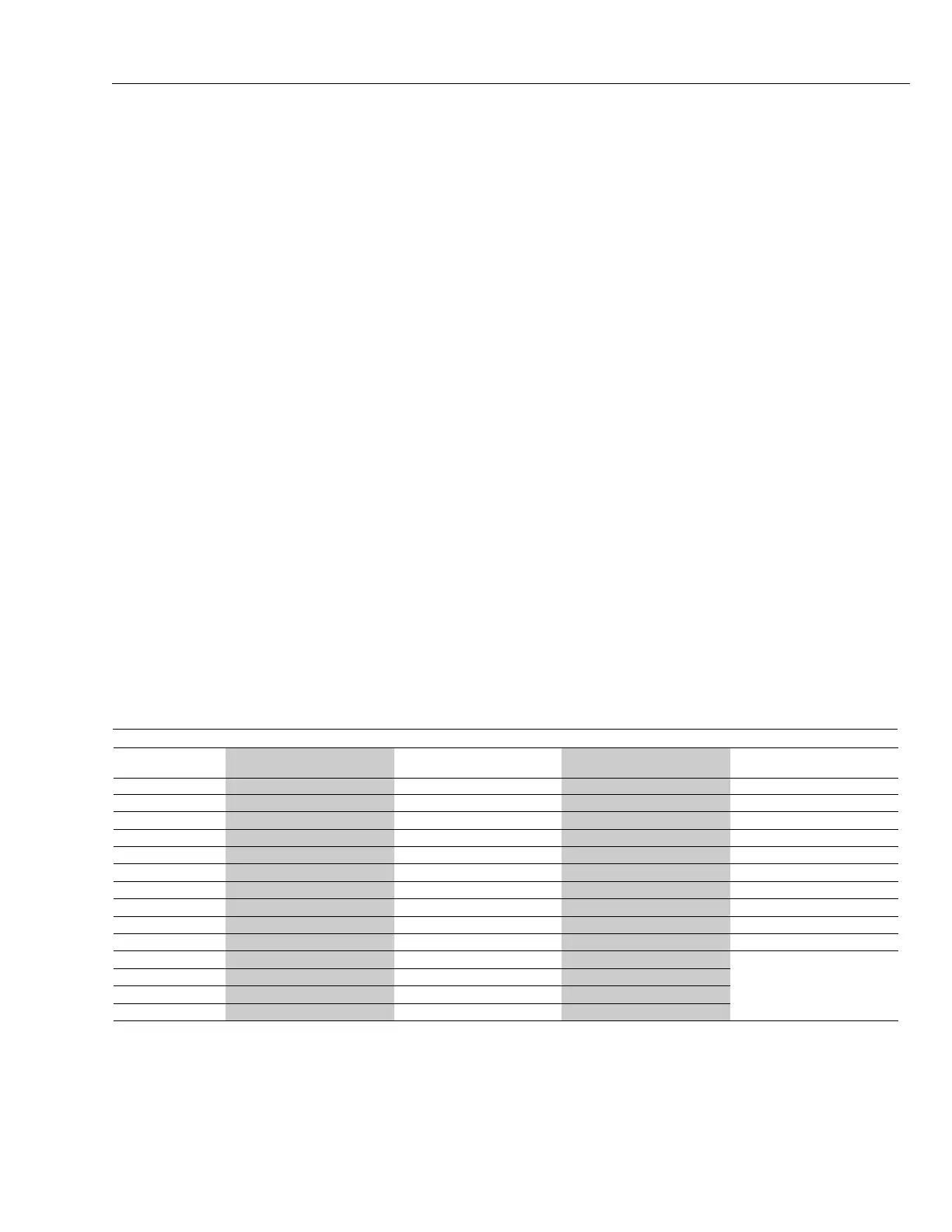

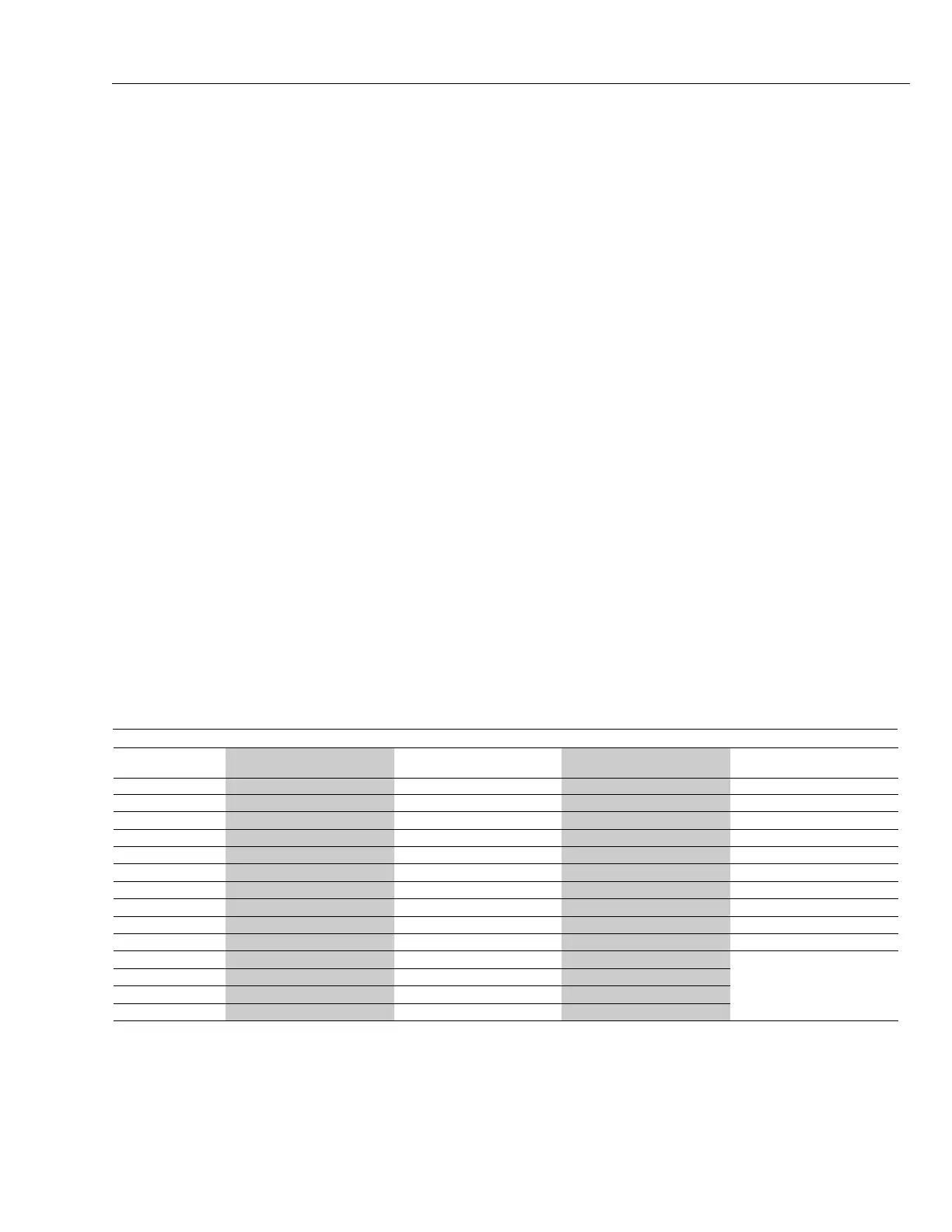

Table 6

Oil Pump Suction Capacity and Filter Selection Chart

Gas/Oil Model Oil Model GPH Power Flame Alternate

Suction Capacity Oil Filter Model Oil Filter

C1-GO-10 70(1) 73410 (Fulflo FB-6)

C1-GO-12 C1-O and C1-OS 70(1) 73410 (Fulflo FB-6)

C2-GO-15 C2-OA and C2-OAS 70(2) 73410 (Fulflo FB-6)

C2-GO-20A C2-OB and C2-OBS 40 70101-100 73410 (Fulflo FB-6)

C2-GO-20B C2-OB and C2-OBS 40 70101-100 73410 (Fulflo FB-6)

C3-GO-20 C3-O 105 70101-100 73410 (Fulflo FB-10)

C3-GO-25 C3-O 105 70101-100 73420 (Fulflo FB-10)

C3-GO-25B C3-O(B) 135 70101-100 73420 (Fulflo FB-10)

C4-GO-25 C4-OA 135 70101-100 73420 (Fulflo FB-10)

C4-GO-30 C4-OB 135 70101-100 73420 (Fulflo FB-10)

C5-GO-30(B) C5-O(B) 250 70101-100 73290 (#72 1” Hayward

C6-GO-30 C6-O 250 70101-100 with 100 mesh basket)

C7-GO-30(B) C7-O(B) 265 70101-100 73290 (#72 1” Hayward

C8-GO-30 C8-O 265 70101-100 with 100 mesh basket)

73290 (#72 1” Hayward

with 100 mesh basket)

OIL SUPPLY PIPING

The C burner is designed for use with light grade fuel oils

- commercial standard grades #2 or #1.

It is recommended that prior to installation all national,

local and other applicable codes be reviewed to ensure

total compliance.

It is recommended that prior to installation, NFPA-31 and

all other national, state, local and other applicable codes

be reviewed to ensure total compliance with their

requirements including, but not necessarily limited to, the

use of anti-syphon valve(s), oil safety valve(s) (OSV), or

other acceptable means to prevent siphoning of the oil

when tank is above burner level. Even if such devices

are not required by code, they should be considered

good installation practice and mandatory when the tank

is above burner level.

Do not install manual valves in the return line between

the pump and the tank unless required by a specific

code. If a manual valve is required, an automatic relief

valve must be installed across the manual valve to

ensure that oil will bypass directly back to the tank in the

event the manual valve is inadvertently left in the closed

position.

Use copper tubing with flare fittings or iron pipe on all

installations. All units must utilize the proper size and

type of suction line oil filters. See this page, Table 6 for

recommended Power Flame oil filters.

If the oil storage system has been used with fuel heavier

than #2 fuel oil, the entire system should be thoroughly

cleaned and flushed before starting up the new system.

Utilize fusible link and/or overhead anti-siphon valves as

appropriate.

If iron pipe oil lines are used on underground tanks, swing

joints utilizing nipples and elbows must be used and

joined together, making certain the piping connections

are tightened as the tank settles. Keep swing joints in the

suction and return lines as close to the tank as possible.

Underground tanks should be pitched away from the

suction line end of the tank to prevent sediment from

accumulating at the suction line entrance. The suction

line should be a minimum of 3" from the tank bottom.

Before starting up the system, all appropriate air and oil

leak tests should be performed. Make certain that the tank

atmospheric vent line is unobstructed.

Refer to page 12, Figure 11 for fuel pump oil piping

connection information. Further information relating to

burner oil piping can be found in Table 6 this page, Figure

11 on page 12, and Figure 12 on page 13.

It is very important to properly size the oil suction line and

oil filter, to provide fuel flow to the burner without exceeding

10" suction pressure (vacuum) at the oil pump suction

port. The method to properly size copper tubing is outlined

on page 12 (Figure 10). Consult Power Flame Customer

Services Department for sizing assistance regarding

iron pipe.

Loading...

Loading...