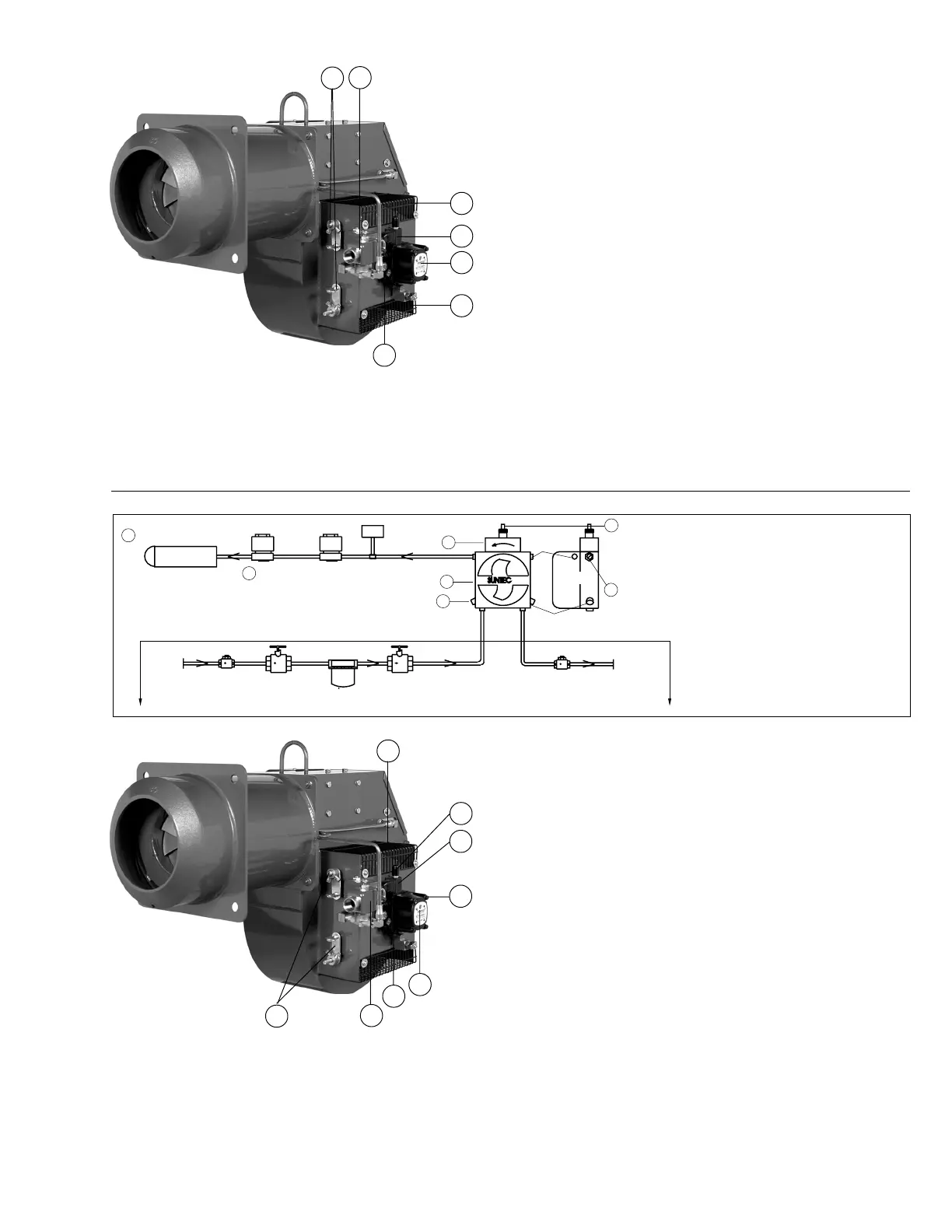

require a spark ignited gas pilot* to provide ignition for the

main oil flame. The nozzle oil flow rate is set by adjusting

the Oil Pump Pressure Regulating Valve (3). Turn clock-

wise to increase the pressure and counter-clockwise to

decrease the pressure to the Nozzle. Normal nozzle

pressure will be 100 to 300 PSI. Refer to page 33, Table

9 to determine specific nozzle pressures and firing rates.

Nozzle pressures are taken at the plugged Nozzle Pressure

Gauge Port (6). The oil on-off flow to the Nozzle is controlled

by the Oil Solenoid Valve (1). The Air Dampers (4) are

adjusted and locked in place with the Air Damper Arms (5).

The burner operates at one fixed firing rate. See page 12,

Figure 11 and pump manufacturer’s bulletin packed with

the burner for more information.

* Not shown in this depiction. See page 3, Figure 1.

Note 1

Component operational sequencing will vary with the specific

Flame Safeguard Control being used. Refer to the specific Flame

Safeguard Control bulletin supplied with the burner for complete

information.

Note 2

The system depicted above is based on the use of an oil pump

manufactured by COMBU Incorporated. If your system uses other

than a COMBU pump, refer to the oil piping diagram and oil pump

manufacturer’s bulletin supplied with the burner for specifics

pertaining to your system.

MECHANICAL OPERATION: The On-Off system uses a

single stage, high suction lift Oil Pump (2) with a Simplex

Oil Nozzle. A direct spark oil ignition system is standard

on typical oil burners (a gas pilot is standard on Gas/Oil

burners), but certain insurance company codes could

1

2

3

5

4

4

6

* By Others Unless Specified

on Order.

** Burners with Remote Pressure

Atomizing Oil Pumps require a

Low Oil Pressure Switch.

CAUTION:

All field piped components must be

mounted in the proper location and

proper direction of oil flow.

CAUTION:

Oil supply pressure to Burner Pump

must not exceed 3 PSI per NFPA

Code.

DO NOT USE TEFLON TAPE

9

Nozzle

1

Oil Solenoid

Valves

Field Piped

Low Oil Pressure Switch **

Oil Pump

2

N.O. Low Fire

Solenoid

7

Nozzle Port

Optional

Inlet Ports

Air Bleed

Valves

Return

Port

Inlet Port

Oil

Pump

Side

View

Check Valve

(At Tank)*

Fuel

Shutoff

Valve*

Fusible Link Valve

(If Required By Code)*

Filter*

Check

Valve*

Inlet

Return

To Tank

Field

Piped

3

Pressure Gauge Test

Port

6

Flat Slot Screw-

driver Low Fire

Pressure

Adjustment

Flat Slot Screw-

driver High Fire

Pressure

Adjustment

Figure 21

Typical Oil Burner with Fixed Air Low Fire Start Fuel/Air Control Mode

8

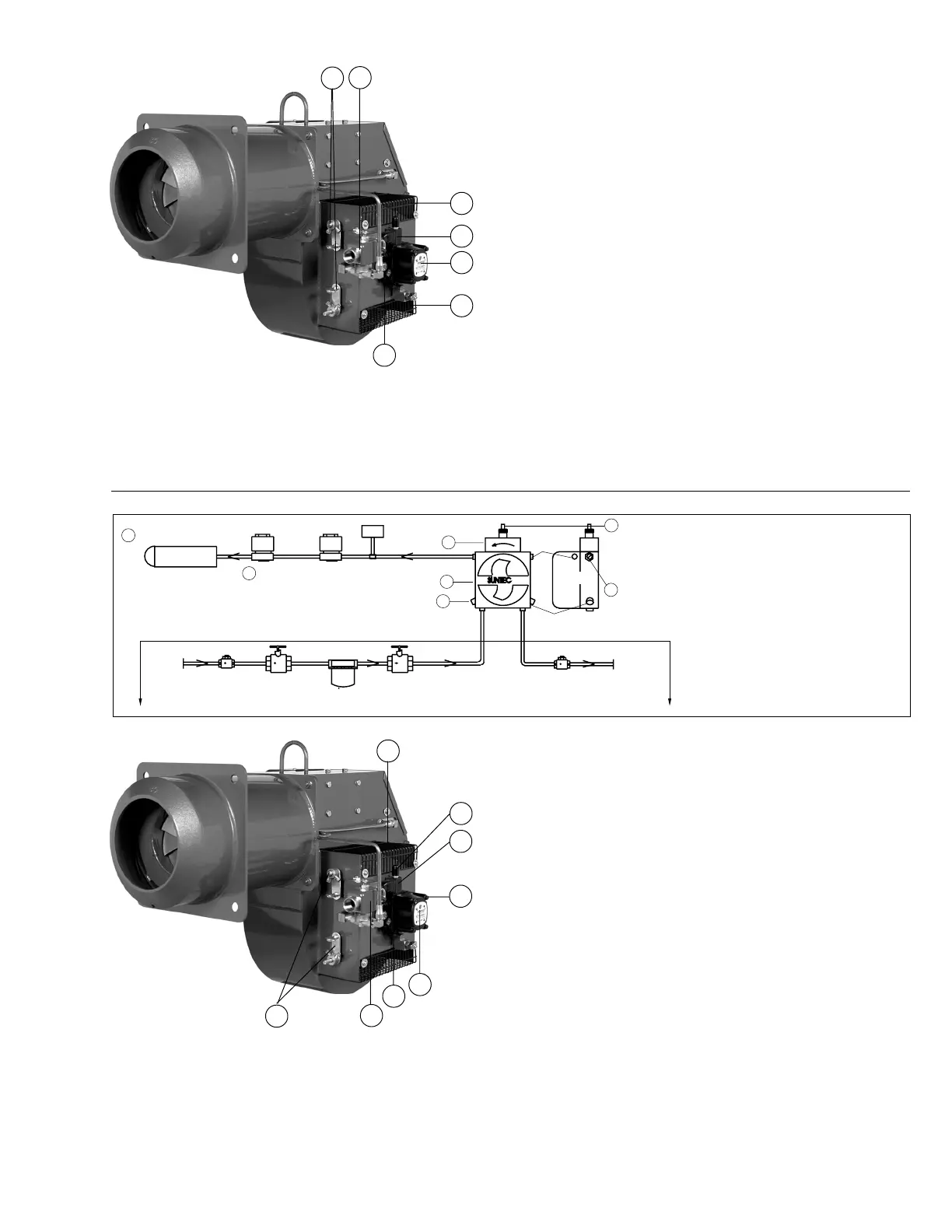

For both high and low fires, turn the adjustment screws

clockwise to increase the pressure and counterclockwise

to decrease the pressure to the Nozzle. Approximate low

fire pressures are 150 to 225 psig and high fire, 200 to

300 psig. Remember, you will be lighting off at full air

and reduced fuel. Raise low fire enough to obtain depend-

able light off with these conditions. The Air Dampers (4) are

adjusted and locked in place with the Air Damper Arms (5) for

correct combustion values at the high fire rate. At light off,

the Main Oil Solenoid Valve (1) is energized, allowing

fuel to flow to the Nozzle. The normally open Low Fire

Solenoid Valve (7) allows a reduced amount of oil to the

Nozzle for low fire start. When the flame is proven by the

flame detector*, the low fire solenoid valve closes,

providing full high fire pressure to the Oil Nozzle. The

burner operates at the high fire position until the system

load demand is satisfied. Refer to page 34, Table 9 for

specific nozzle pressures and firing rates. See page 12,

Figure 11 and the pump manufacturer’s bulletin supplied

with the burner for additional information.

* Not shown in this depiction. See page 3, Figure 1.

Note 1

The system depicted uses a two-step Suntec oil pump. If a pump

that does not have the integral two-step function has been

specified and supplied, it will be provided with an N.C. nozzle

bypass oil solenoid valve and a separate adjustable low fire relief

valve. Refer to the oil piping diagram and the oil pump manu-

facturer’s bulletin supplied with the burner for the specifics on

your system.

MECHANICAL OPERATION: The fixed air low fire start

system uses a two-step, two-stage Oil Pump (2) with a

Simplex Oil Nozzle. A direct spark oil ignition system is

standard on typical oil burners (a gas pilot is standard on

Gas/Oil burners), but certain insurance company codes

could require a spark ignited gas pilot* to provide ignition

for the main oil flame. The nozzle flow rate pressures are

taken at the Plugged Pump Nozzle Pressure Gauge Port (6).

The low fire oil flow rate is set by adjusting the Oil Pump

Low Pressure Regulator (8). The high fire oil flow rate is

set by adjusting the Oil Pump High Pressure Regulator (3).

3

Model C-O

8

7

6

1

2

5

4

C17

Rev.304

Loading...

Loading...