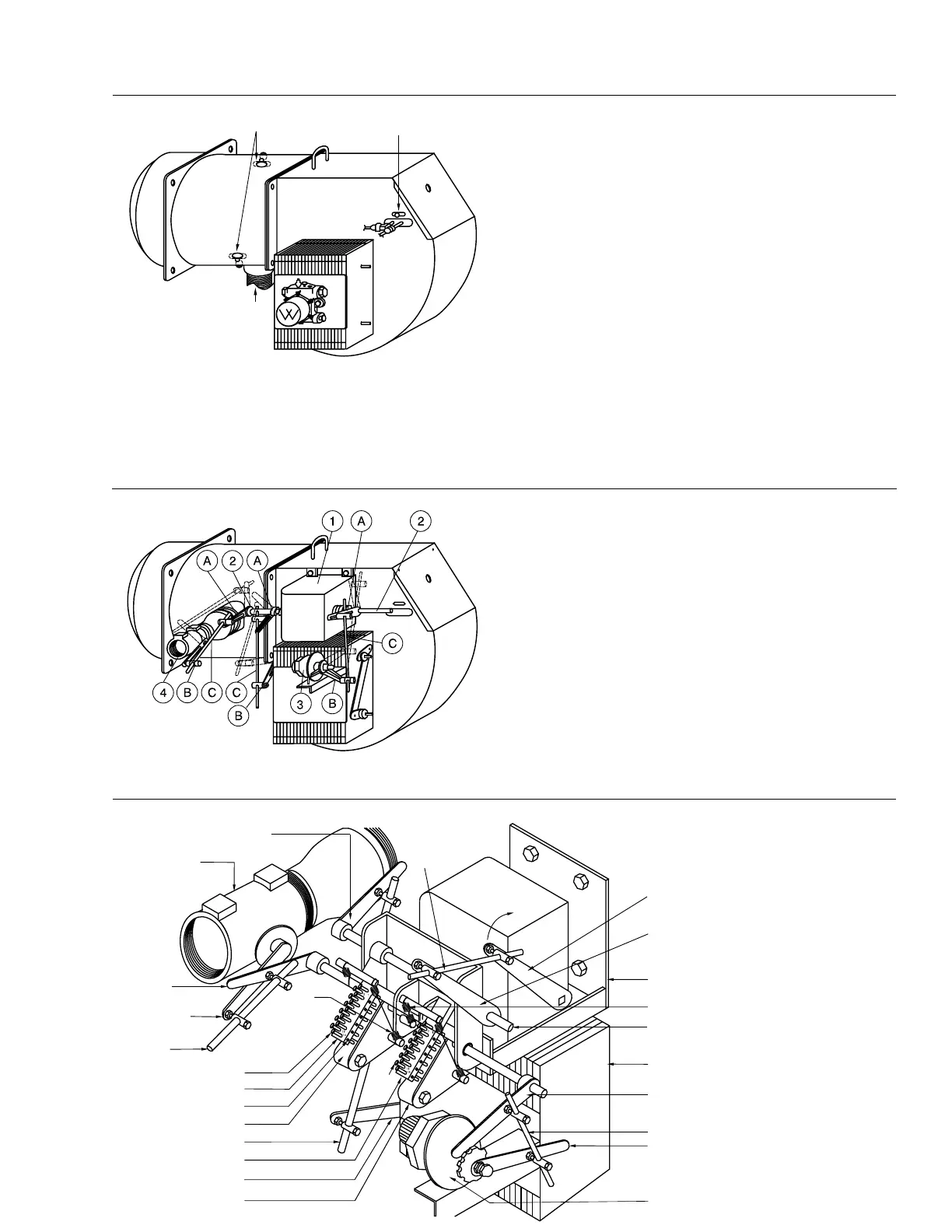

Gas or Gas/Oil Burner Fuel/Air Premix Adjustment - Gas, Oil or Gas/Oil Burner Diffuser Adjustment

moving it forward decreases the premix air. Generally, the

best (quietest/smoothest) operation is in the full forward

position with minimum premix air. The premix adjustment

is set at the factory in the full forward position. To attain

the best combustion results for specific job conditions,

change position in small increments.

DIFFUSER POSITION ADJUSTMENT

Moving the blast tube diffuser assembly fore or aft on gas

or oil firing will move the flame front (point of retention) in

order to attain the best (quietest/smoothest) combustion

for specific job conditions. If the initial midway point factory

setting does not provide satisfactory results, move fore or

aft in small increments to achieve the best combustion

results. If unit is oil or combination gas/oil, the attached,

flexible copper oil nozzle line will move fore or aft with

the assembly. When firing on oil, moving the assembly

forward will tend to broaden the flame pattern and moving

it back will narrow the flame pattern. Similar results are

obtained on gas, but observation of sound and combus-

tion tests are the best determinants of results on either

gas or oil.

Gas/Air Premix Adjustment Knob

Blast Tube Diffuser Position Adjustment

Gas Inlet

Figure 26

FUEL AIR PREMIX

ADJUSTMENT(OPTIONAL)

The adjustable premix blast tube (optional) incorporates an

adjustable gas/air premix within the burner firing head. The

premix configuration is primarily used for cylindrical combus-

tion chambers or high heat release pressurized fireboxes.

Moving the adjustment knob back increases the premix air;

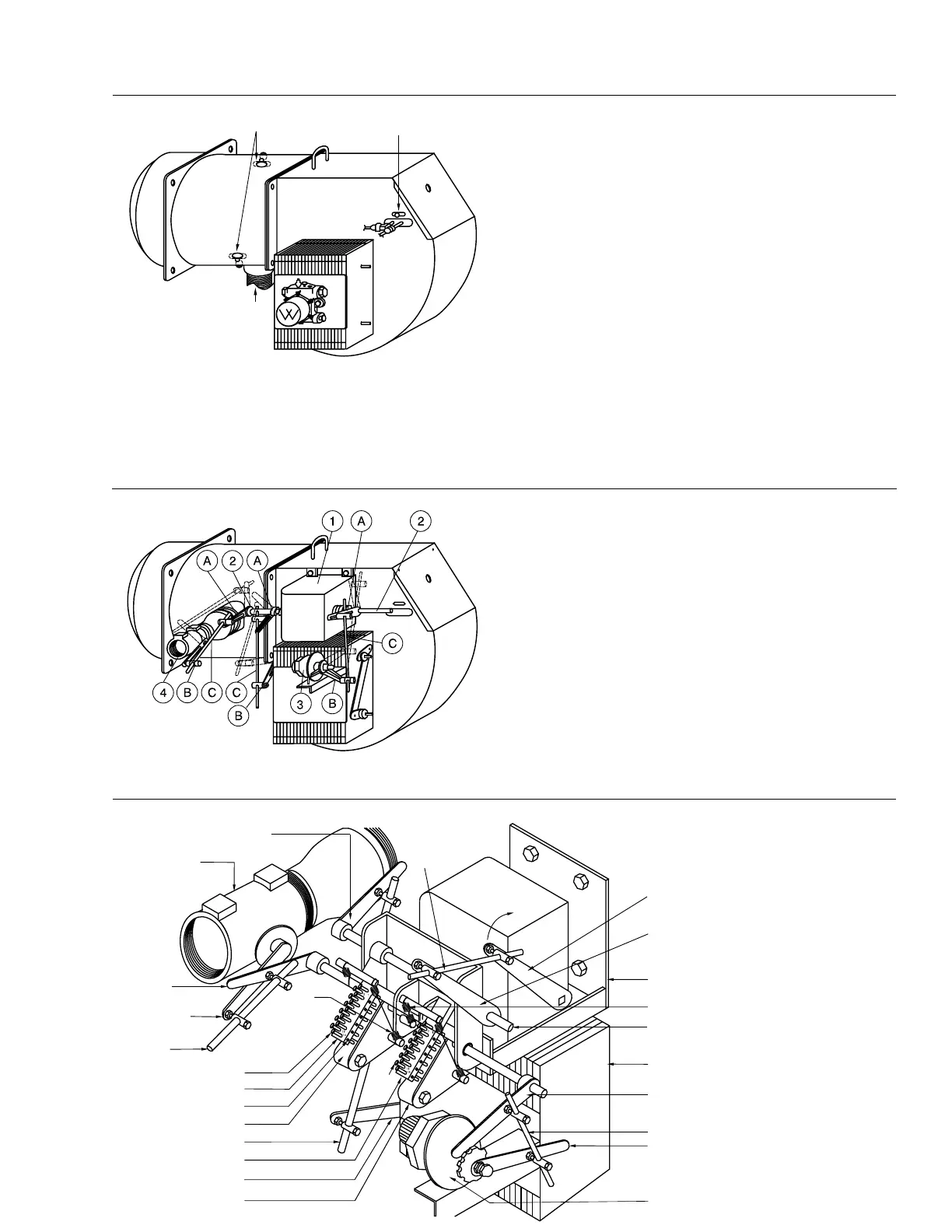

Gas/Oil Linkage Adjustment For Full Modulation Standard System

Typical general linkage arrangement for combination

gas/oil full modulation burner, shown in low fire light

off position. Dotted lines indicate approximately high

fire position. When making adjustments, make certain

the motor can make its full 90

o

stroke without any

linkage binding.

Driver Arms (A) connected to the Modulating Motor (1)

Jack Shaft (2) will increase the travel of the Driven Arms

(B) as the Linkage Rod (C) ball joint is moved away from

the Jack Shaft. The travel of the Driven Arms will be

increased as the Linkage Rod ball joint is moved toward

the shaft of the driven device.

1. Modulating Motor

2. Jack Shaft

3. Modulating V Port Oil Valve

4. Modulating Butterfly Valve

A. Driver Arms

B. Driven Arms

C. Linkage Rods

Figure 27

Air Damper

Driver Arm

Modulating

Butterfly

Gas Valve

Gas Fuel

Driver Arm

Gas Fuel

Driven Arm

Gas Fuel

Linkage Rod

Cam Screw #13

Gas Fuel Cam Arm

Thread Binding Set Screw

Gas Fuel Cam Follower

Cam

Spring

Cam

Screw

#13

Oil Fuel Driven Arm

Oil Fuel Linkage Rod

Oil Fuel Driver Arm

Modulating Motor Bracket

Jack Shaft Driven Arm

Modulating Motor Driver Arm

Open

Modulating

Motor

Jack Shaft

Linkage Rod

Jack Shaft

Figure 28

Gas/Oil - Detail and Adjustments on Modulating Varicam

TM

Characterized Fuel Metering System.

For complete adjustment instructions refer to bulletin

VA1588 Varicam Adjustment Instructions included in

the information shipped with the burner.

Air Damper Linkage Rod

Oil Fuel Cam Follower

Air Damper Housing

Oil Fuel Cam Arm

Air Damper Driven Arm

Modulating Oil Valve

Typical Cam Spring

C22

Rev.304

Loading...

Loading...