9

Remove the protective coating from the saw table sur-

face with a soft cloth moistened with a good commer-

cial solvent.

NOTE: Do not use acetone, gasoline, or lacquer thin-

ner to remove the protective coating, as it can dam-

age plastic parts and painted areas. Do not use an

abrasive pad on the table top.

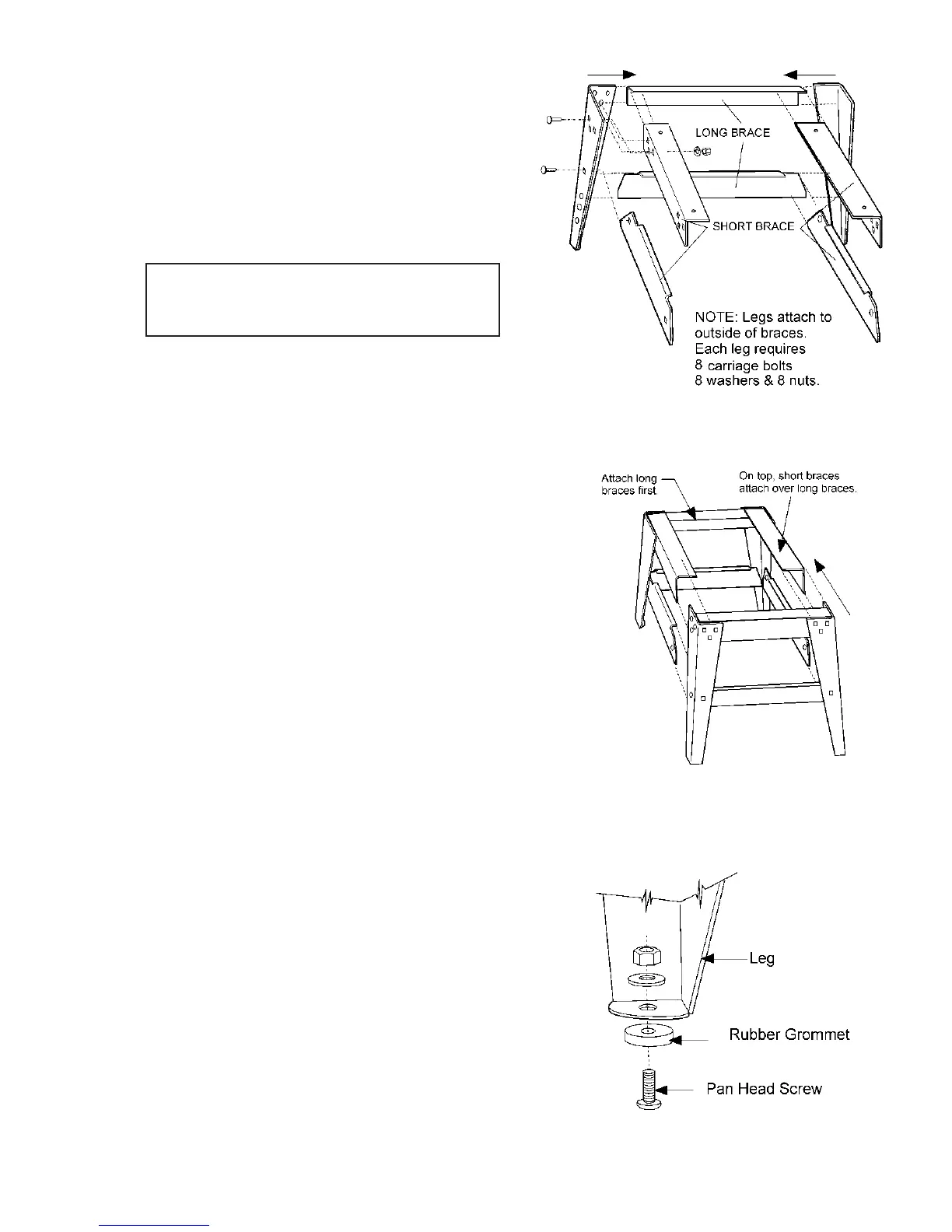

STAND ASSEMBLY

Tools required

12mm & 10mm wrenches

phillips screwdriver.

Note: Except for the rubber feet, only finger tighten

all nuts. Stand assembly nuts should be fully tight-

ened only after the saw has been attached to the stand.

If you are using a mobile base, the stand should be

tightened only after placing the saw in the mobile base.

TIP: It may be easier to assemble stand in an up-

side-down position. Illustrations are shown right side-

up for the purpose of clarity.

1. Assemble two leg sets using the long cross

braces attached to the inside of the legs. The lower

cross braces go into first set of square holes located

approximately center of each leg. See Figure 1. The

bottom holes on the legs do not apply to this ma-

chine. Use (32) 5/16-18 x 5/8 carriage bolts, (32) 5/16

hex nuts, and (32) 5/16 flat washers to assemble the

stand.

2. Attach the four short braces to one set of legs as

shown in Figure 2.

3. Complete the stand assembly by attaching the

other set of legs as shown in Figure 2.

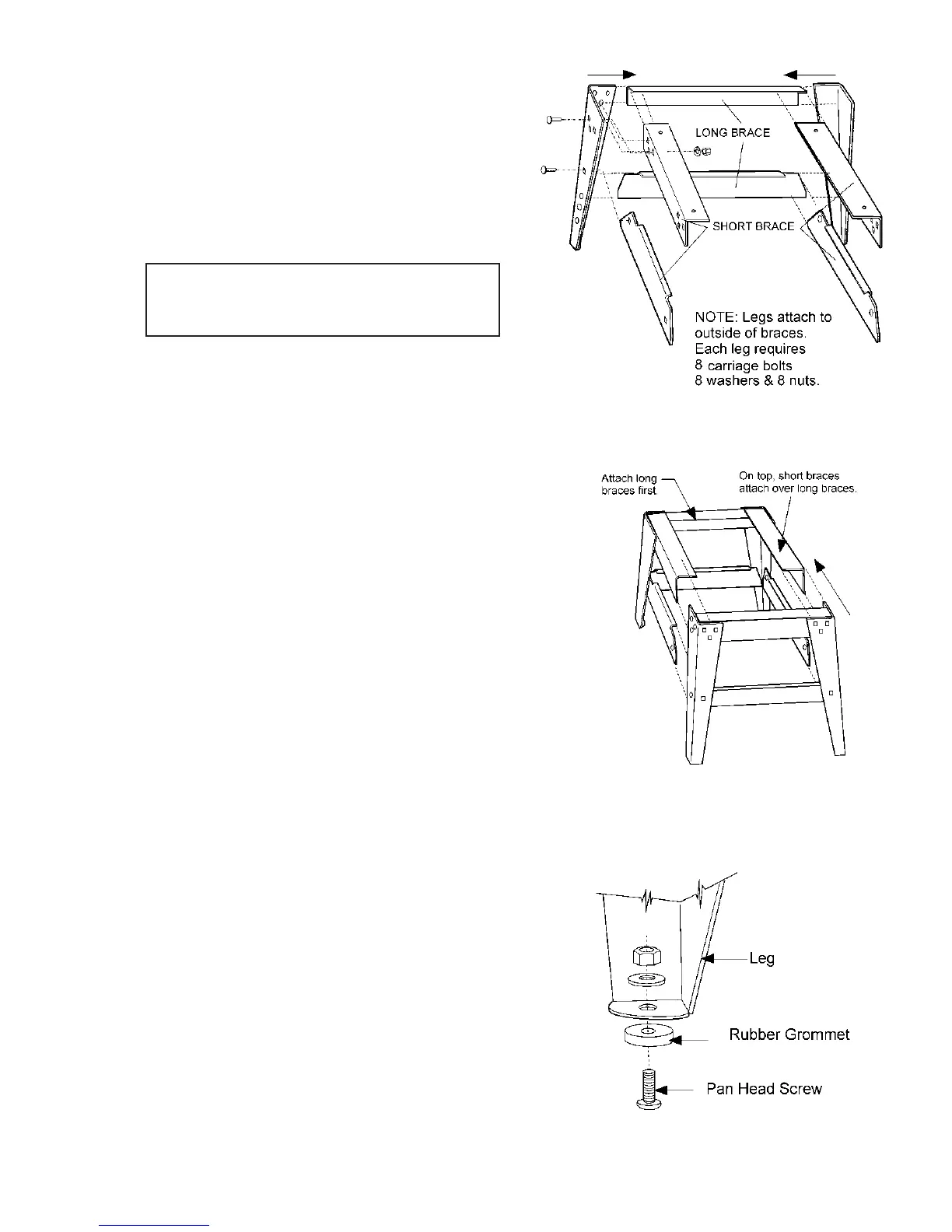

4. To attach rubber feet to each leg, first use a

Phillips screwdriver and screw the 1/4-20 x 1 pan head

screw through the recessed hole of the rubber grom-

met as shown in figure 3. Push the screw through the

hole provided at the bottom of each leg, and tightly

fasten down with 1/4 flat washer and 1/4 nut.

5. Remember, leave all other stand assembly nuts

only finger tight!

FIGURE 1

FIGURE 2

FIGURE 3

Loading...

Loading...