Maintenance

EGM-4 Operator's Manual – Version 4.19

- 46 -

Servicing The EGM-4

Fuse

The EGM-4 circuitry is protected by a 1A (5x20 mm) fuse. This is located in a black fuse

holder located at the back of the instrument (see page 11 for location). If this requires

replacement, please ensure that the correct size and type of fuse is used.

It is very easy to determine if a fuse is good or bad. Usually, a bad fuse will be burned out

and visually obvious. The true test is to use an ohm meter. Place one lead from the ohm

meter on one end of the fuse and the other lead on the opposite end of the fuse. If it reads 0,

you have a good fuse. Anything else, the fuse is bad and should be replaced.

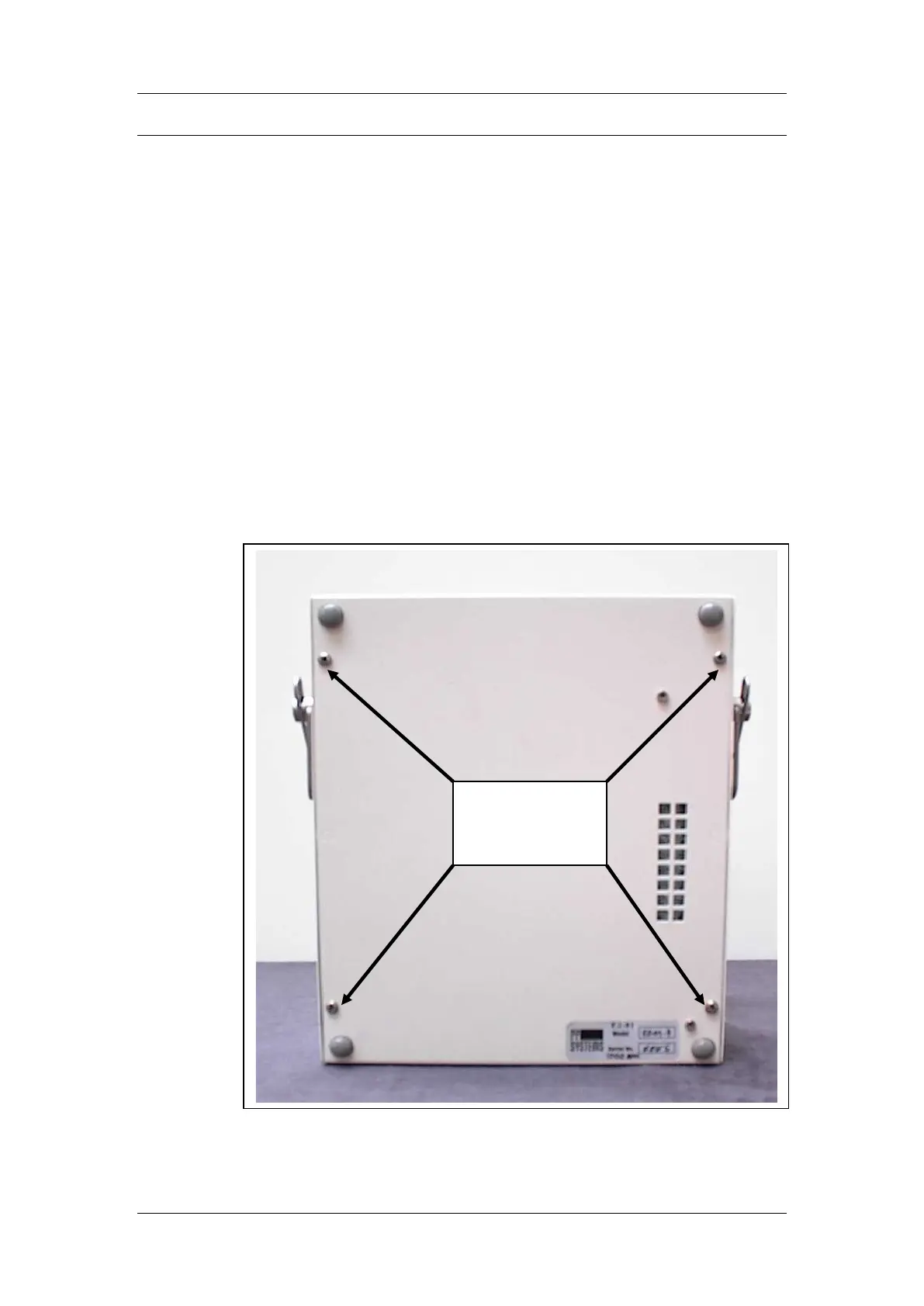

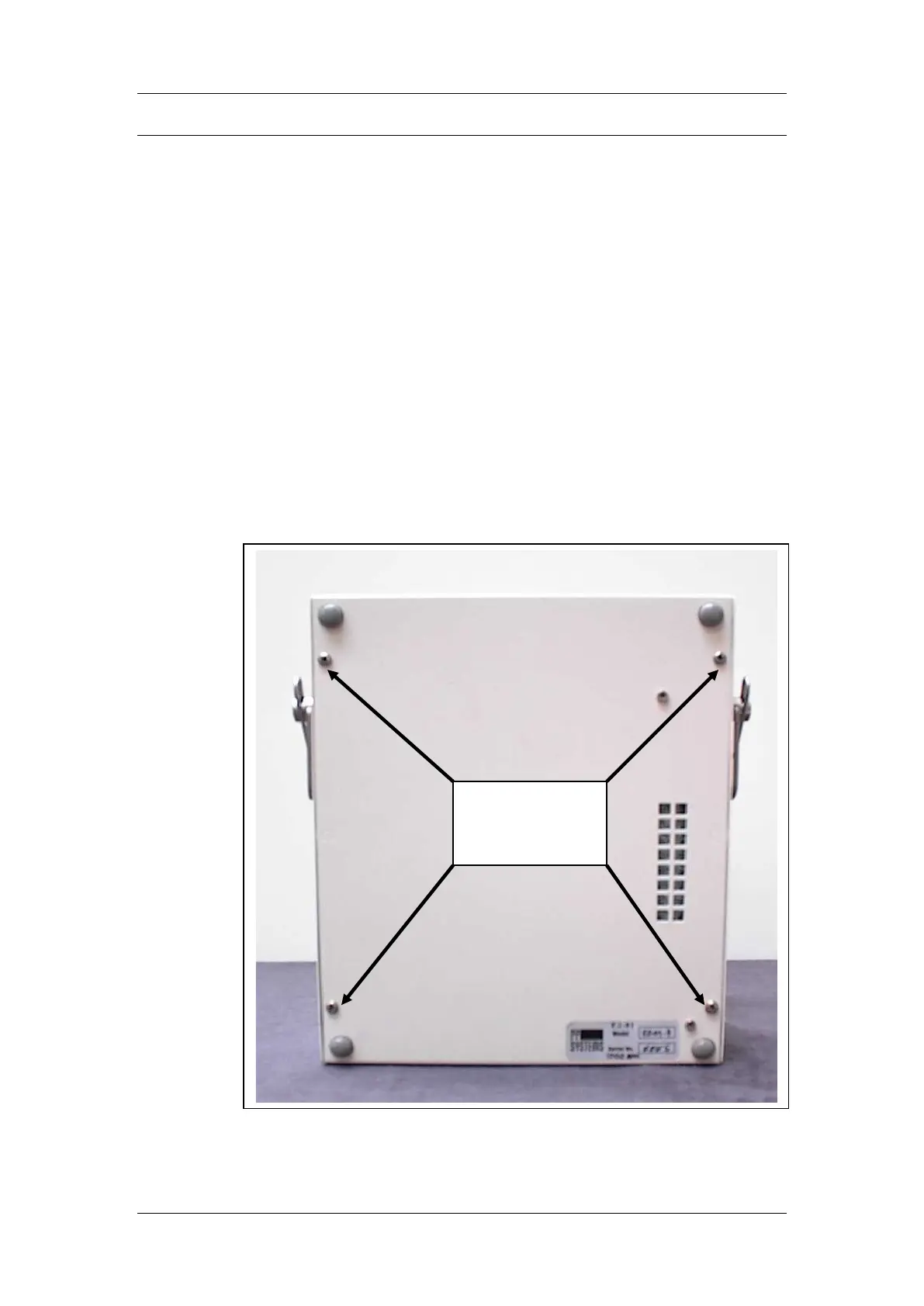

The EGM-4 enclosure must be removed in order to service the following items:

• Infrared Source

• EPROM

• Zero Valve

• 12V Lead Acid Battery

• Air Sampling Pump

Screws To Access

Internal EGM-4

Loading...

Loading...