SX™ Operator Manual

©

Original Printed in English

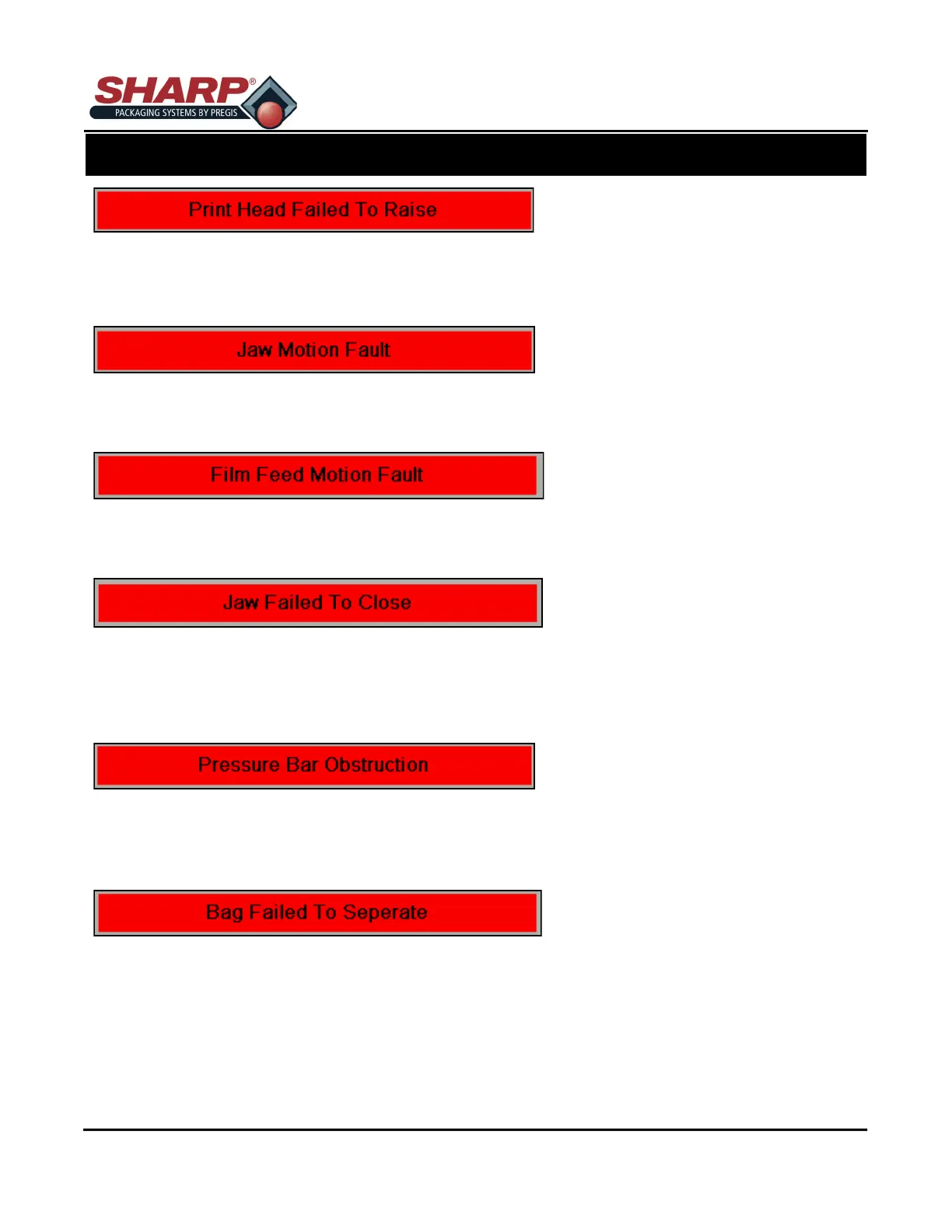

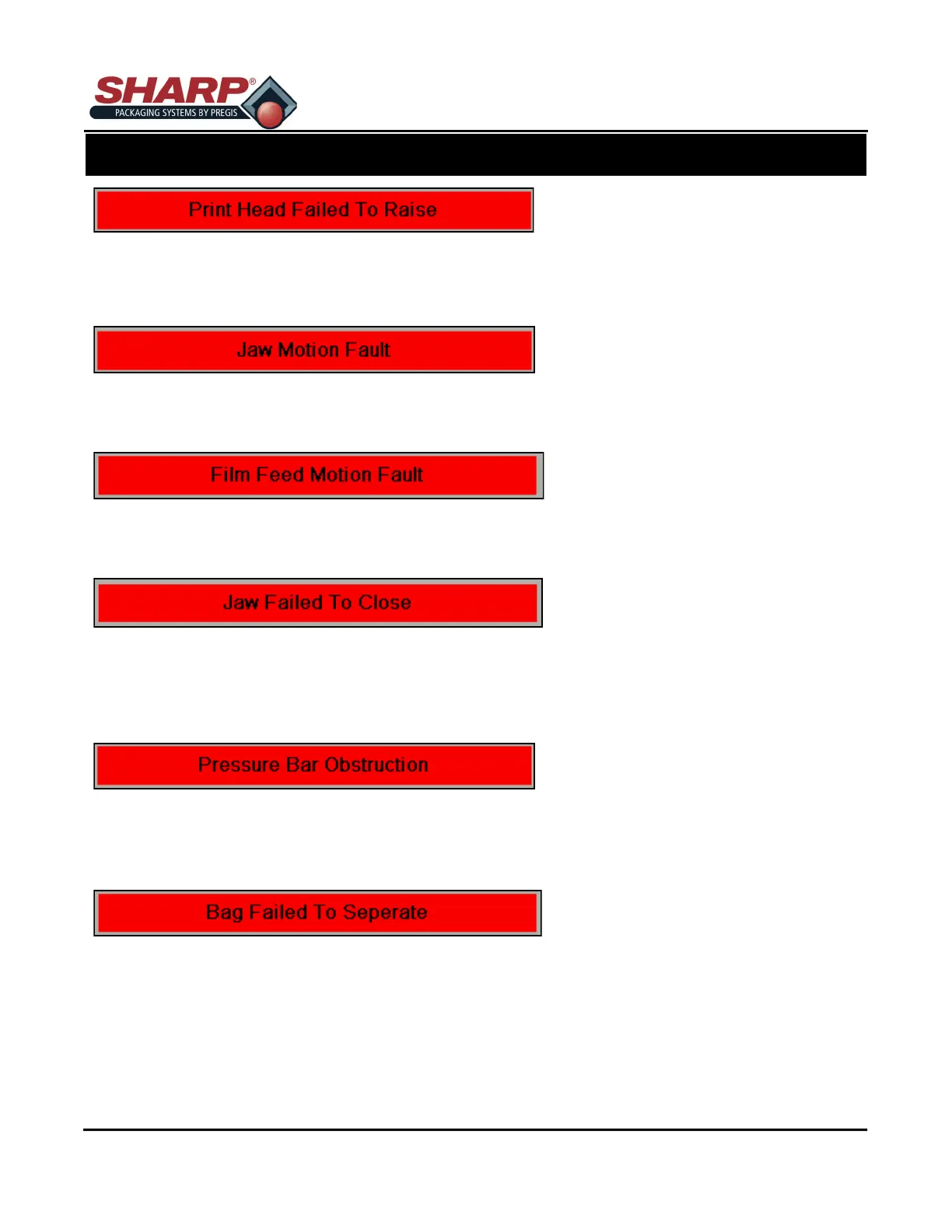

CAUSE: The Lower Print Head PLC output O-05 was turned off, but Input I-05 stayed on.

REMEDY: Lower Print Head Solenoid may have failed or proximity sensor is not positioned correctly

with the target. Check PLC I/O circuits.

CAUSE: The Jaw Axis detected a motion fault

REMEDY: Reset the fault. If problem persists, rehome the Jaw.

CAUSE: The Film Axis detected a motion fault

REMEDY: Reset the fault. If problem persists, lower the Feed Speed setting.

CAUSE: The commanded motion did not complete before the fault timer expired. The Jaw Closed Sensor

must change states as the jaw moves in to the sealing position. Also the Jaw may have mechanically lost its po-

sition.

REMEDY: Reset the fault and Rehome the Jaw.

CAUSE: The pressure bar attempted to close, but was blocked by an obstruction.

REMEDY: This is usually a part that did not drop past the pressure bar. Increase the Filler Drop Timer

setting.

CAUSE: The Bag Edge Photo-eye did not detect the trailing edge of the film as the web was backing up.

REMEDY: Check that the Photo-eye is correctly sensing the film in front of it.

It should only turn on when it sees the film in front of it. It should turn off just as the trailing edge of the film un-

blocks the eye. The eye may need to be taught from the service screen or it might need to be cleaned.

FAULT & ALERT MANAGEMENT

HMI FAULT MANAGEMENT

5-2

Loading...

Loading...