Alternator

Battery indicator light is mounted

on

the

instrume~t

panel in front

of

the driver to signal when alternator

1s

not

chargi11g

. When this

occurs

under

normal ope-

rating conditions, vehicle should be driven only as far

as necessary to reach a point

of

safety.

Engine alarm system

Engine is equipped with

an

alarm system to indi

ca_te

low oil pressure and

high

engine temperature.

1COrln

and uhot water» indicators are located

on

the instru-

ment panel

in

front

of

the driver. In addition. an alarm

buzzer sounds when either condition occurs.

The automatic shut-down device, operating through a

time delay safety control relay interconnected with the

alarm system, will stop the engine when

one

of

these

abnormal conditions

occurs

.

Stopping engine

1. Apply parking brake and make sure that transmis-

sion shift lever is placed in neutral position. This will

ensure that the transmission neutral start safety swit-

ches are closed and witl allow future restarting of the

engine.

2. Wait

30

seconds, allowing engine to idle, then turn

ignition key to uoff

11

position. This will activate control

shut-off mechanism and stop engine.

•

WARNING:

If i

gn

iti

on

sw

itch does not stop engine,

or

in case of an emergency, push

on

engine

emer

-

gency

stop switch. This will release an

air

choke

v~lve

cam

and stop engine. Engine emergency stop switch

should be returned to its original position after engine

has stopped by releasing the switch. This warning does

not apply to vehicles equipped with a turbocharged

engine.

Engine emergency stop

When engine

does

not stop after ignition key switch

has been turned to off position

or

when it gets out

of

control it can be stopped through use of the «engine

emergency stopu switch located

on

front switch panel.

This engine emergency stop system is not required

on

turbocharged engine.

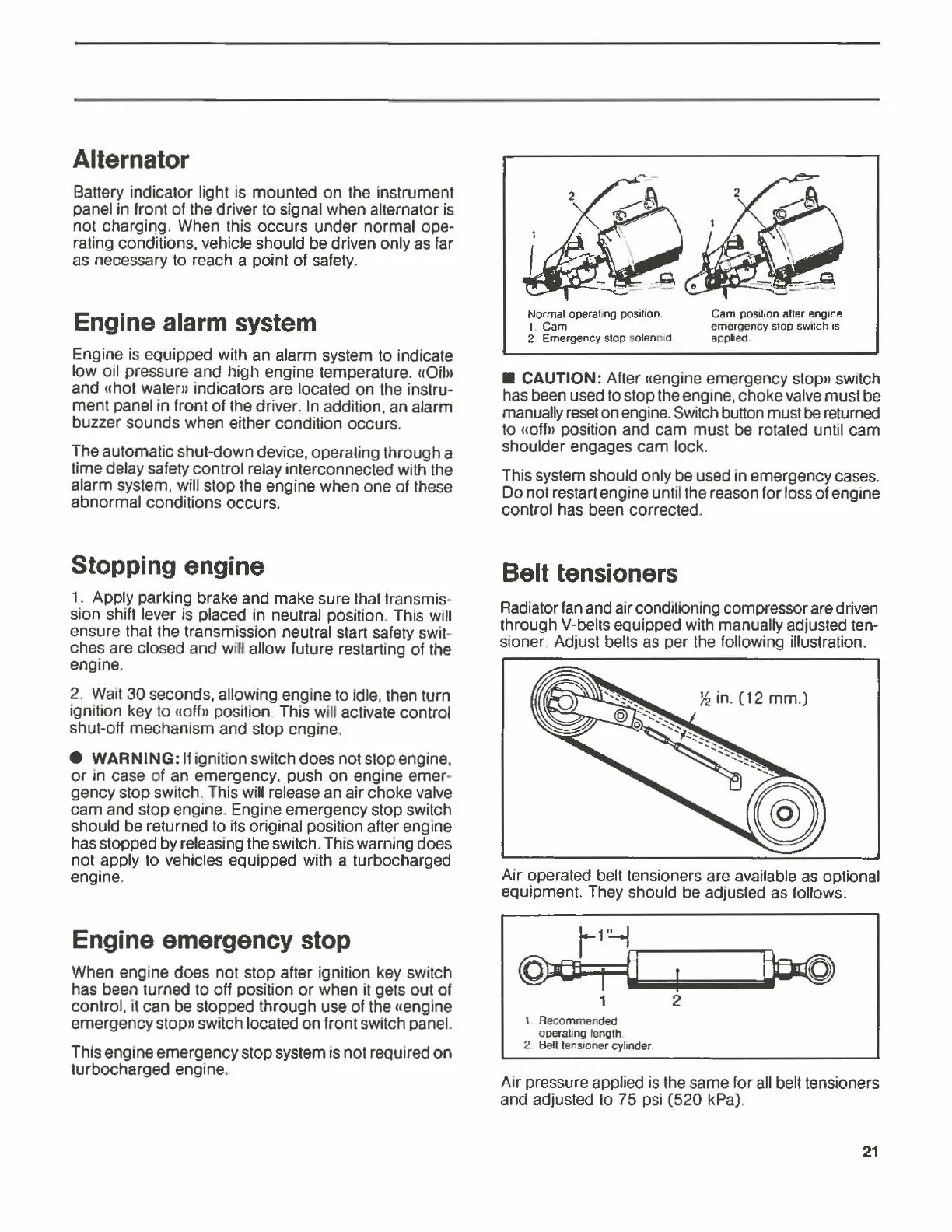

Normal operat ng position

t

Cam

2 Emergency stop solen

0o

d

Cam

pos1t1on

alter engine

emergency stop switch

1s

applied

•

CAUTION:

After uengine emergency stopn switch

has been used to stop the engine, choke valve must

be

manually

reset

on engine. Switch button must be returned

to «offn position and

cam

must

be

rotated until

cam

shoulder engages

cam

lock.

This system should only be used in emergency

cas~s.

Do

not restart engine until the reason for loss

of

engine

control has been corrected.

Belt tensioners

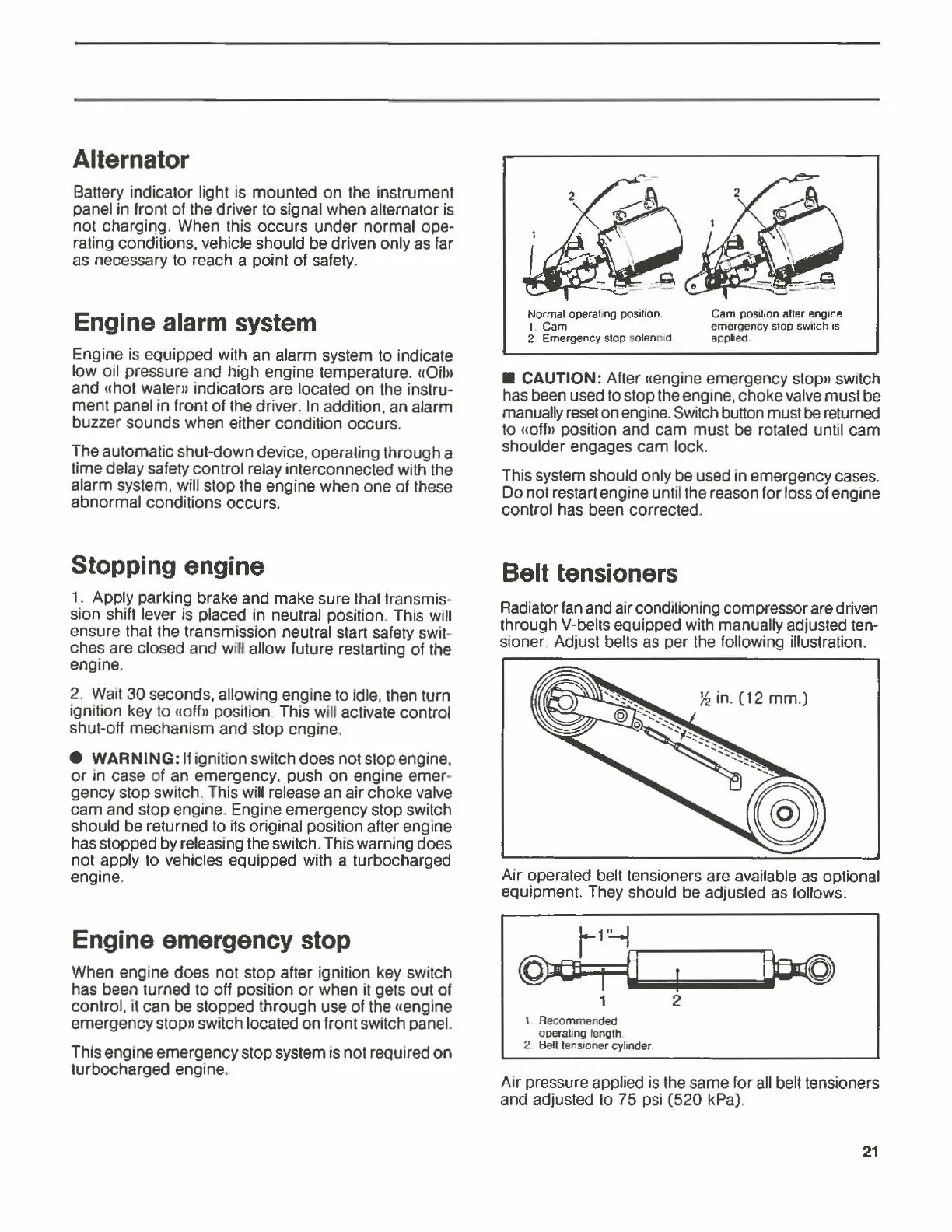

Radiator fan and air conditioning compressor are driven

through V-belts equipped with

manu~lly

~djusle~

ten-

sioner. Adjust belts as per the following

1llustrat1on.

Air operated belt tensioners are available as optional

equipment. They should be adjusted as follows:

1 2

I Recommended

operating

length

2. Belt tensroner cylinder.

Air pressure applied is the same for all belt tensioners

and adjusted to 75 psi

(520

kPa).

21

Loading...

Loading...