70284701 9

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3

Troubleshooting

IMPORTANT: Refer to wiring diagram for aid in

testing tumbler components.

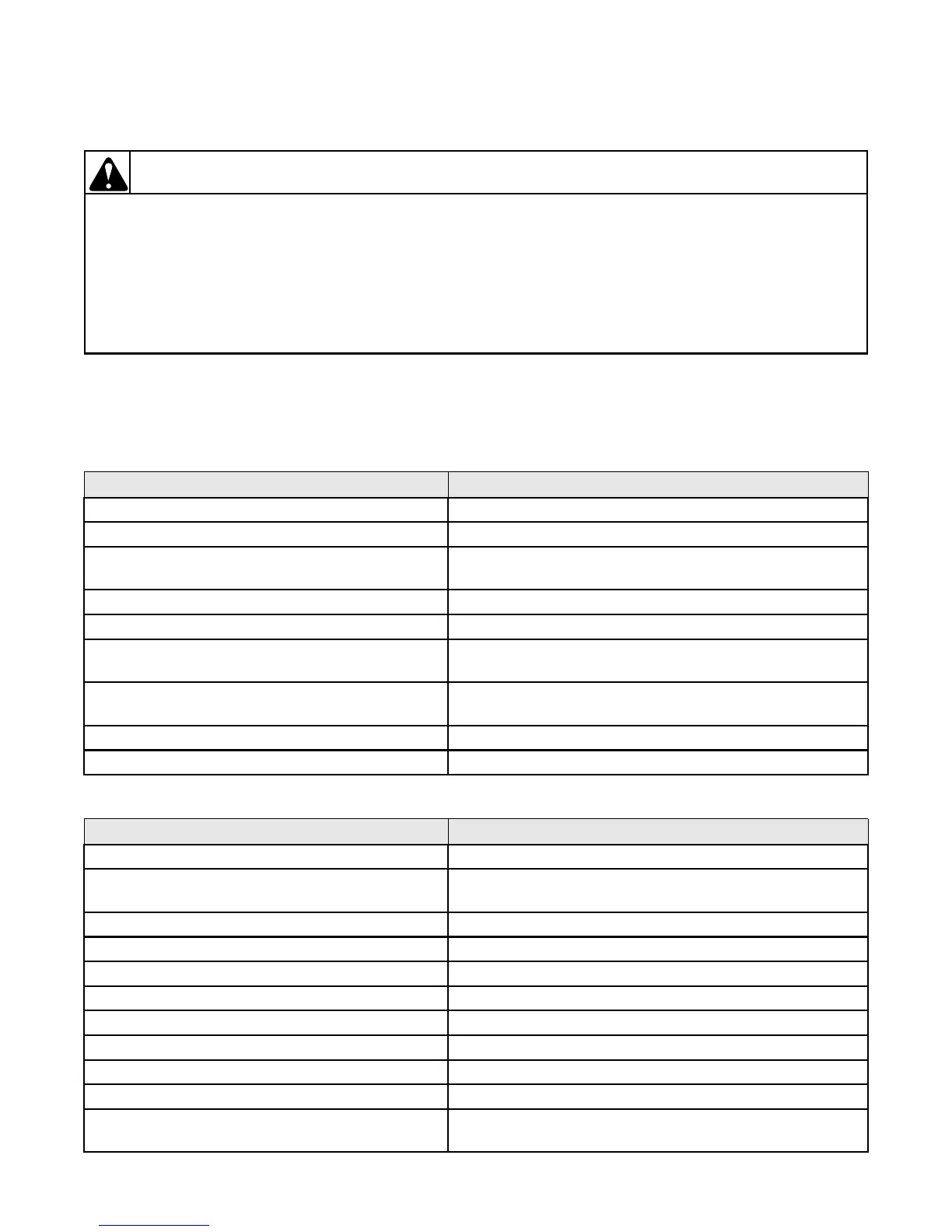

1. TUMBLER DOES NOT START

2. MOTOR DOES NOT START

POSSIBLE CAUSE TO CORRECT

Inoperative motor relay. • Test relay and replace if necessary.

Loading door is open. • Close loading door completely.

Drying timer is in an off position. (Manual Timer

Models)

• Turn drying timer on.

Incorrect amount of coins inserted into coin drop. • Check that proper amount of coins are inserted.

Inoperative coin drop. • Test coin drop and replaced if inoperative.

PUSH-TO-START button not properly activated.

(Manual Timer Models)

• Press and hold in push-to-start button for three seconds.

Electrical power off or circuit breaker or fuse

blown.

• Check power supply, or replace fuses.

Lint panel open. • Close and lock lint panel.

Blown fuse on tumbler. • Check fuse (in junction box) and replace if necessary.

POSSIBLE CAUSE TO CORRECT

Electrical power off or circuit breaker fuse blown. • Check power supply, or replace fuses.

Loading door switch or lint panel switch not closed

or inoperative switch.

• Close door or test switch and replace if inoperative.

Door switch improperly adjusted. • Refer to Adjustments Section for door switch adjustment.

Start circuit not complete. • Press and hold in push-to-start button for three seconds.

Inoperative motor. • Have motor tested and replace if inoperative.

Broken, loose, or incorrect wiring. • Refer to wiring diagram.

Fan or fan motor binding. • Replace fan or motor assembly.

Cylinder or cylinder motor binding. • Replace cylinder, bearing, rollers, or motor assembly.

Inoperative transformer. • Test and replace if necessary.

Inoperative motor relay. • Test relay and replace if inoperative.

Inoperative airflow switch. (Only on manual timer

and rotary coin drop.)

• Test switch, replace or adjust as required.

Loading...

Loading...