MACHINE DESCRIPTION

Page 34 of 99 USER MANUAL PSPC UM-PSPC-06-E/10-2012

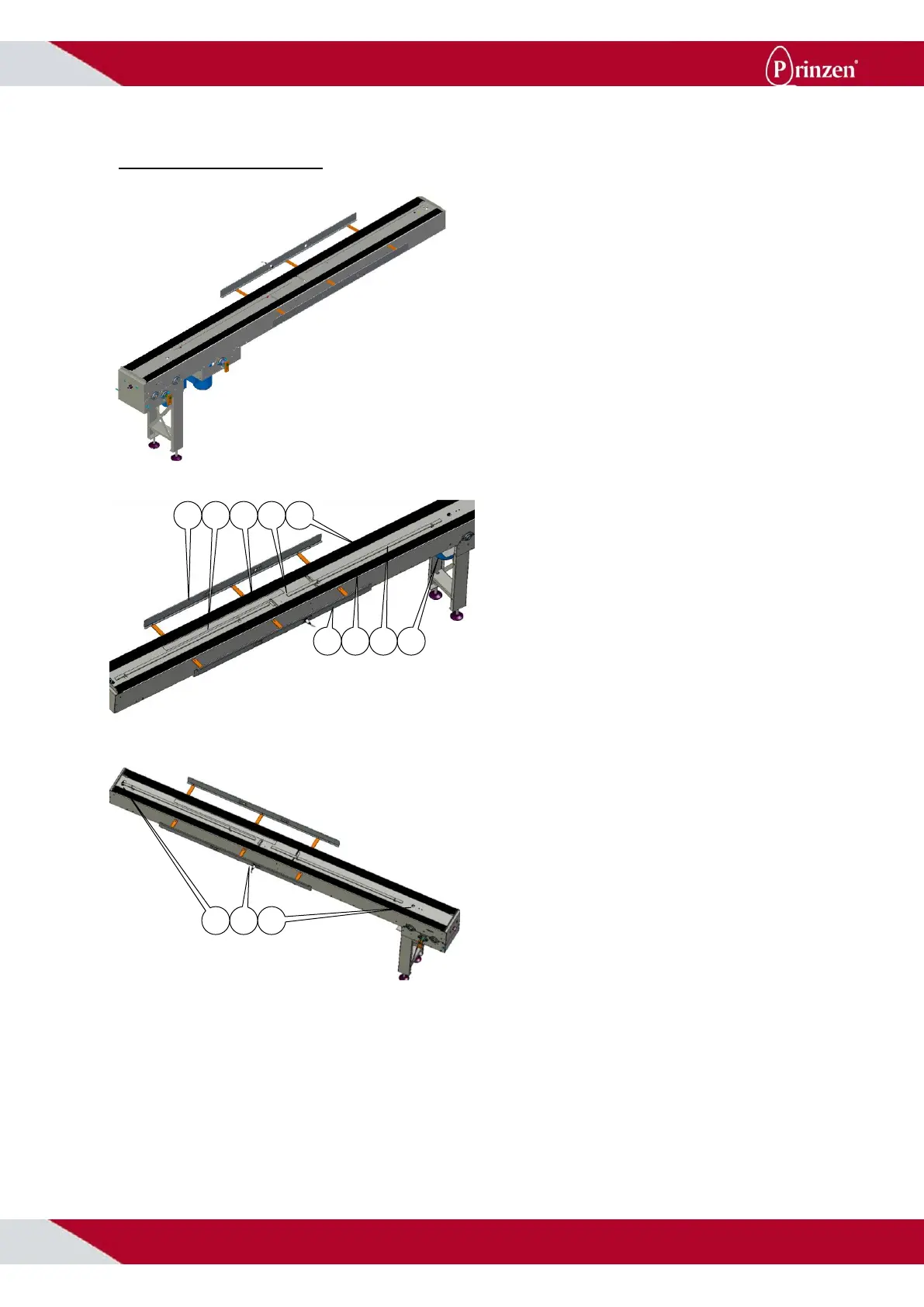

OUTPUT CONVEYOR

Use:

The output conveyor transports empty trays

from the denesters towards the tray set

position underneath the vacuum head, and full

trays towards the position where they are

manually or automatically removed.

Construction:

The output conveyor consists of:

1 Conveyor

2 30-cell tray guide

3 30-cell stopper

4 Hatch tray guides

5 Hatch tray stoppers

6 Drive mechanism

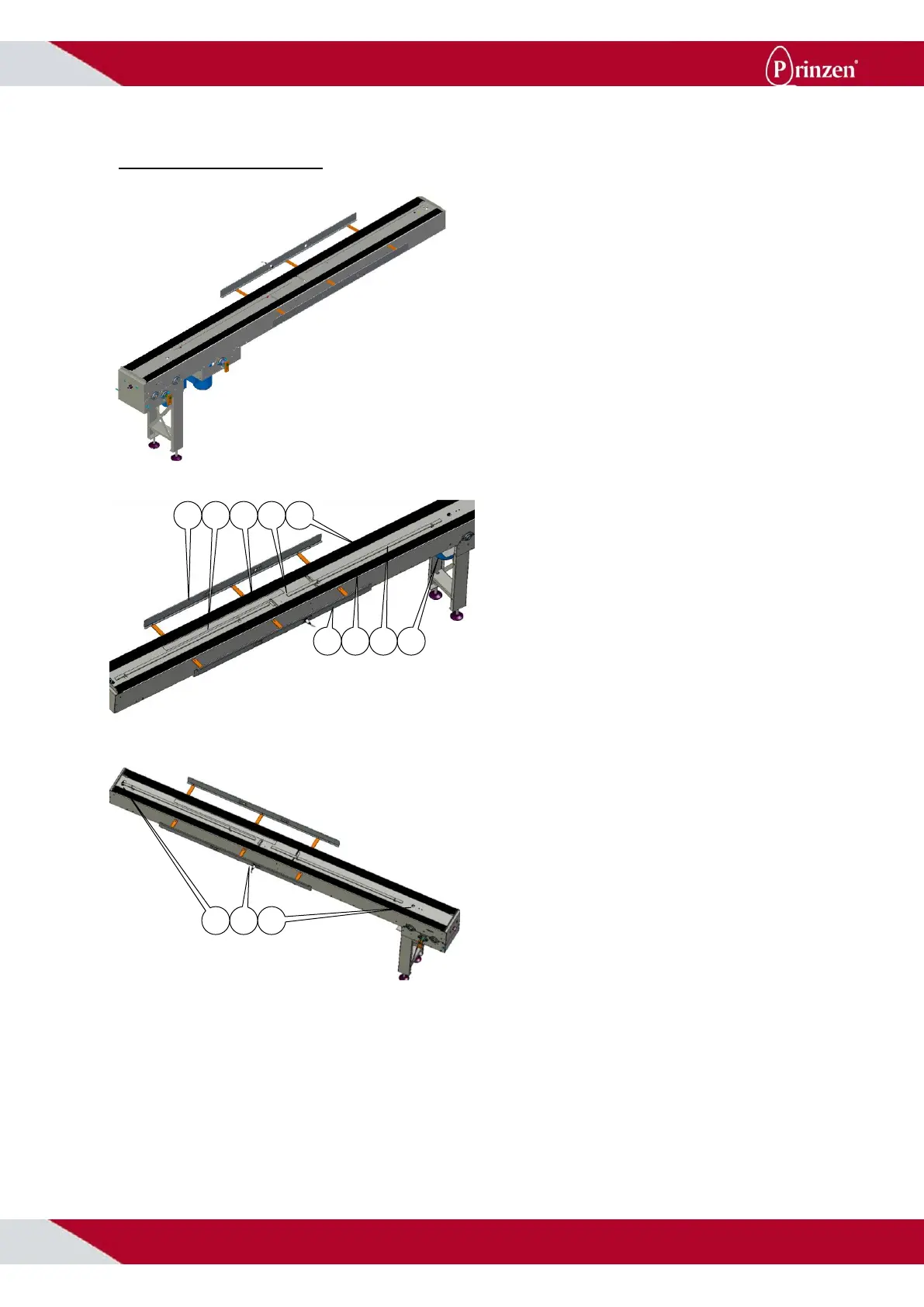

For fast changeover over of tray types by

means of repositioning of the output conveyor,

a mobile version of the output conveyor is

available.

This conveyor has 2 food with rollers instead of

the 1-fixed feet.

Process 30-cell tray:

When the start denester sensor (10) is OFF,

the denester drops a tray on the conveyor.

This tray is transported towards the 30-cell

stopper. As soon as the tray is detected by the

tray present sensor (11) the packer’s vacuum

head places the eggs into the tray. Now the

stopper releases the full tray while at the same

time stopping the next empty tray. The full tray

is transported towards the end of the conveyor

where it needs manual removal or automatic

removal by the easy stacker.

When the tray present sensor (11) turns OFF,

the stopper releases the waiting empty tray

and stops it again at the tray set position.

Process hatch tray:

A tray is automatically supplied after 5 cycles

of the vacuum head (125 of 150 eggs are

placed in the previous tray).

This tray is transported towards 1

st

hatch tray

stopper. As soon as the tray is detected by the

tray present sensor (11) the packer’s

combination vacuum head places the first 25

eggs into one side of the tray. Moves back to

the packer to pick up another 25 eggs and

places these eggs into the other side of the

tray. Then the 2

nd

hatch tray stopper moves up,

the 1

st

hatch tray stopper moves down and the

hatch tray is transported towards the 2

nd

stopper. Again the combination vacuum head

places 25 eggs in both sides of the tray. This

sequence is repeated for the last 50 eggs.

When the hatch tray is full, it is transported

towards the end of the conveyor, where it

needs manual removal (detected by a sensor

(12)).

Loading...

Loading...