Jive Up / QM-710 Stand Up 47

Rev.2.0

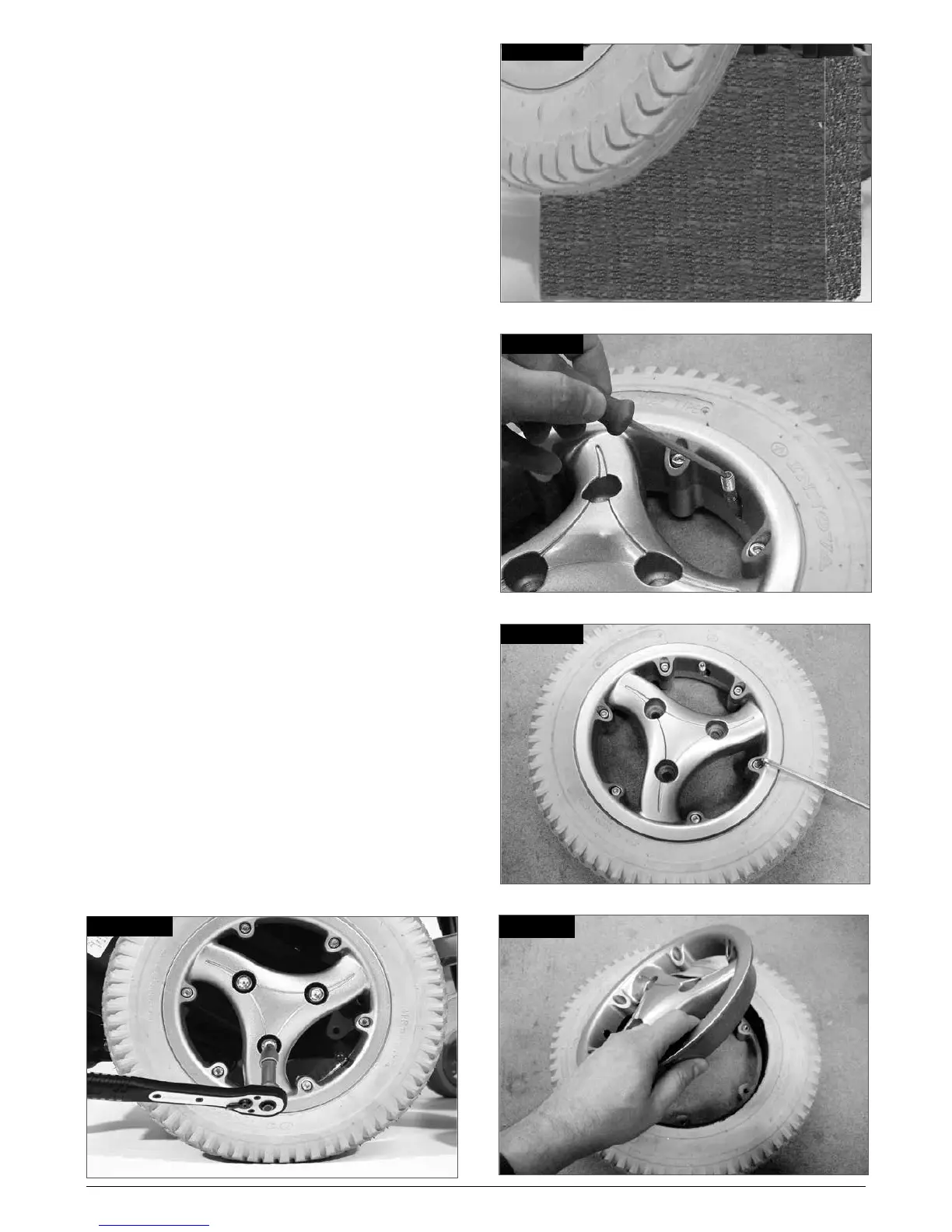

14.1.3 Drive wheel tyre repair

To remove the wheel/tyre:

Please see below and next page for photographs.

• Use a 8.0 mm hex key to loosen the 3-Socket studs,

(Fig. 14.2).

• Jack the wheel up and support it using blocks,

• (Fig. 14.3).

• Remove the 3 studs and pull the wheel away from

the hub.

• Remove the valve cap and let the air out of the tyre

by gently pressing the valve stem with a small screw

driver, (Fig. 14.4).

• There are 6 rim studs that must be loosened/

tightened in the number order shown, (Fig.14.5).

• Use a 5.0 mm Allen key to release/tighten the studs.

(Fig. 14.5) .

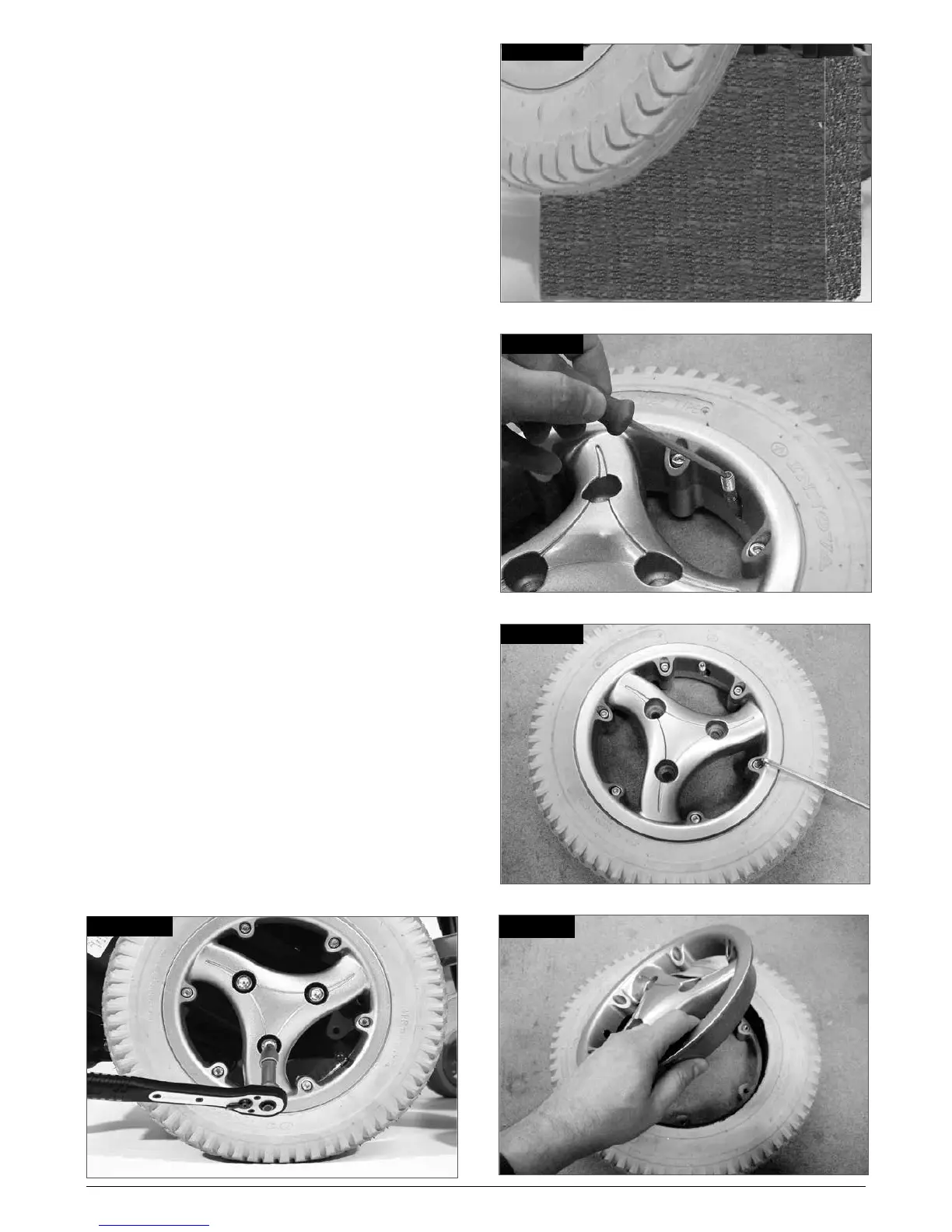

• Lift the inner rim off the tyre wall (Fig. 14.6).

• Lift the tyre and tube off the outer rim, (Fig.14.7).

• Gently get a hold of the inner tube just behind the

valve.

• Carefully feed the tube out of the tyre, (fig.14.8).

• Ensure all parts are clean before reassembling,

(Fig.14.9).

To refit

• Place the tube inside the tyre and rest the tyre on

the outer rim.

• Align the valve stem with the cut out in the rim.

• Face the valve stem outward.

• Place the inner rim over the tyre, tube and outer rim.

• Align the cut out to fit over the valve stem and match

it up to the cut out in the outer rim, (Fig.14.10).

• Make sure the stud mounts are in line on both rims.

• Tighten the studs in the sequence shown in Fig.14.5,

taking care not to pinch the tube.

• Slowly inflate to the pressures quoted in section

14.1.1 .

• Refit the wheel back onto the motor shaft and fix it

safely with the 3 studs to a torque of 47Nm.

For solid tyres the sequence is the same, just discount

the references to the inner tube and valve.

Fig. 14.2

Fig. 14.6

Fig. 14.4

Fig. 14.5

1

2

3

5

4

6

Fig. 14.3

Loading...

Loading...