17.2.1. Inserting text into strings

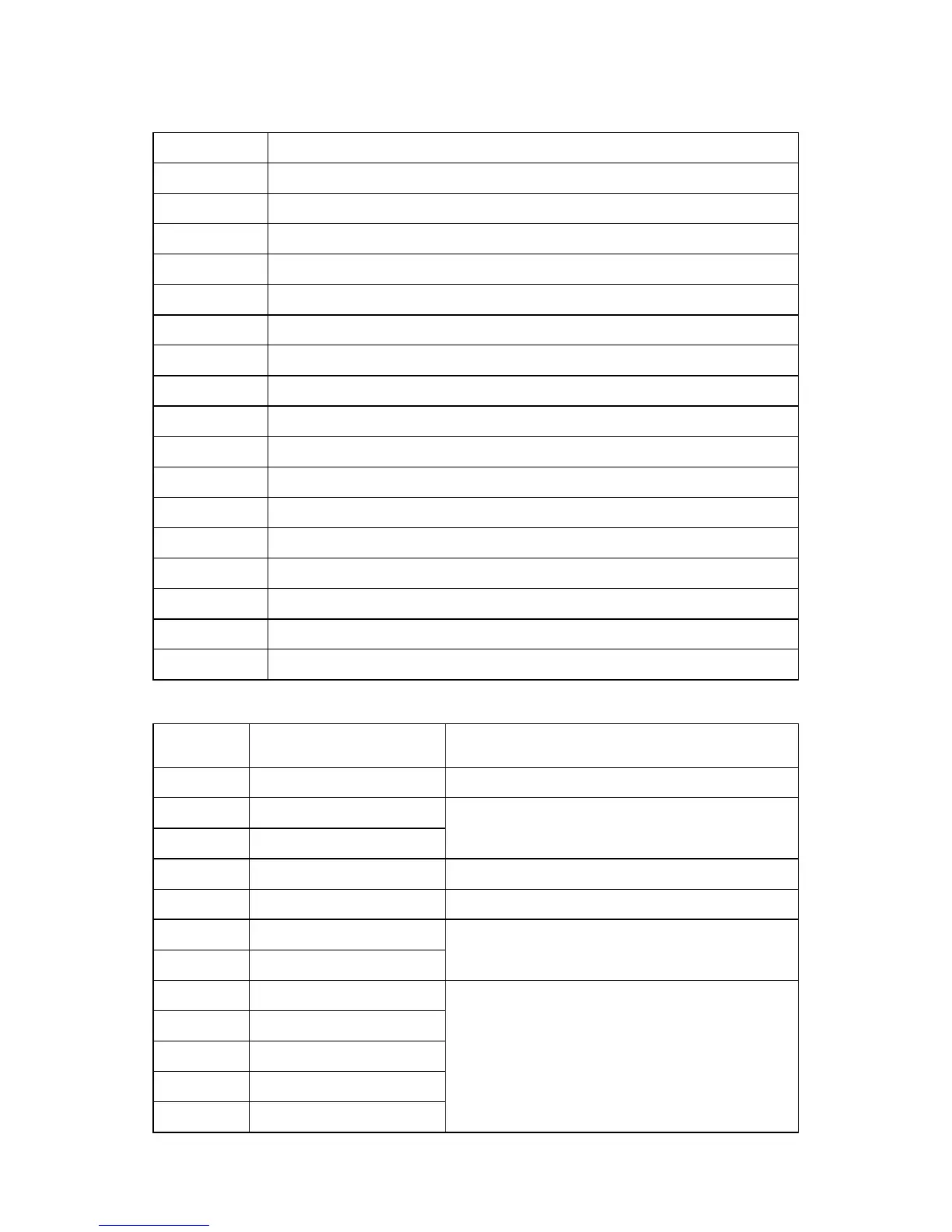

Variables available in all working modes and having the same value

Printout of a single character “%”

%N Current net mass in basic measuring unit

%d Current date

%t Current time

%i Balance factory no.

%R Software no.

%P Project no.

%U User no.

%F Name of an active working mode

%C Date and time of last completed adjustment process

Type of last completed adjustment process

%I Deviation in last completed adjustment process

%1 Code 1

%2 Code 2

%3 Code 3

%4 Code 4

%5 Code 5

%6 Code 6

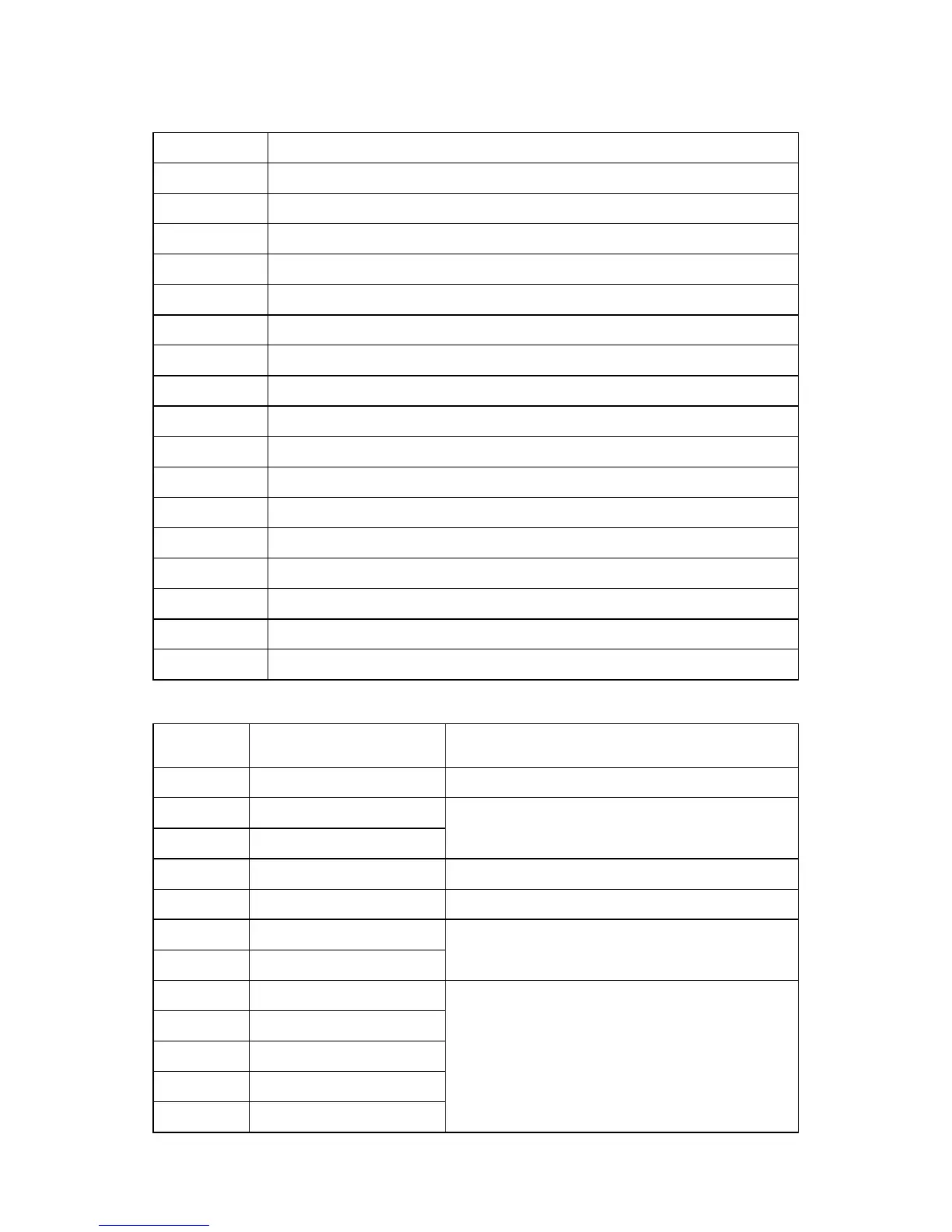

Variables dependent on a currently enabled working mode

Variable Description

Working mode in which the variable is

active

%W Mass of a single part PARTS COUNTING

%H HI high threshold

CHECKWEIGHING

%L LO Low threshold

%Z Target mass DOSING

%B Reference mass PERCENT SETUP

%A Filter

ANIMAL WEIGHING

%b Threshold (limit)

%i Liquid

DENSITY DETERMINATION

%p Procedure

%c Temperature

%a Liquid density

%v Sinker volume

Loading...

Loading...