en-65

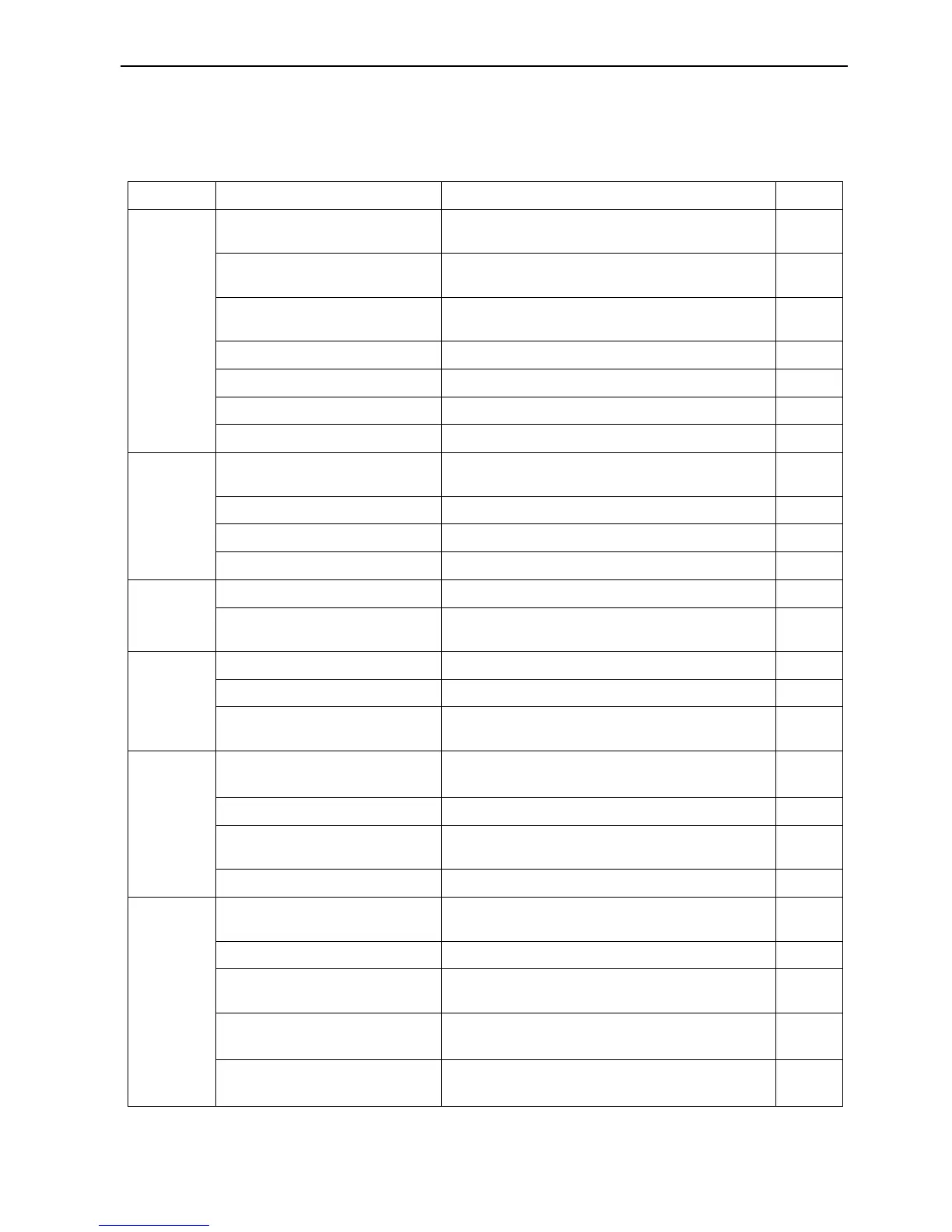

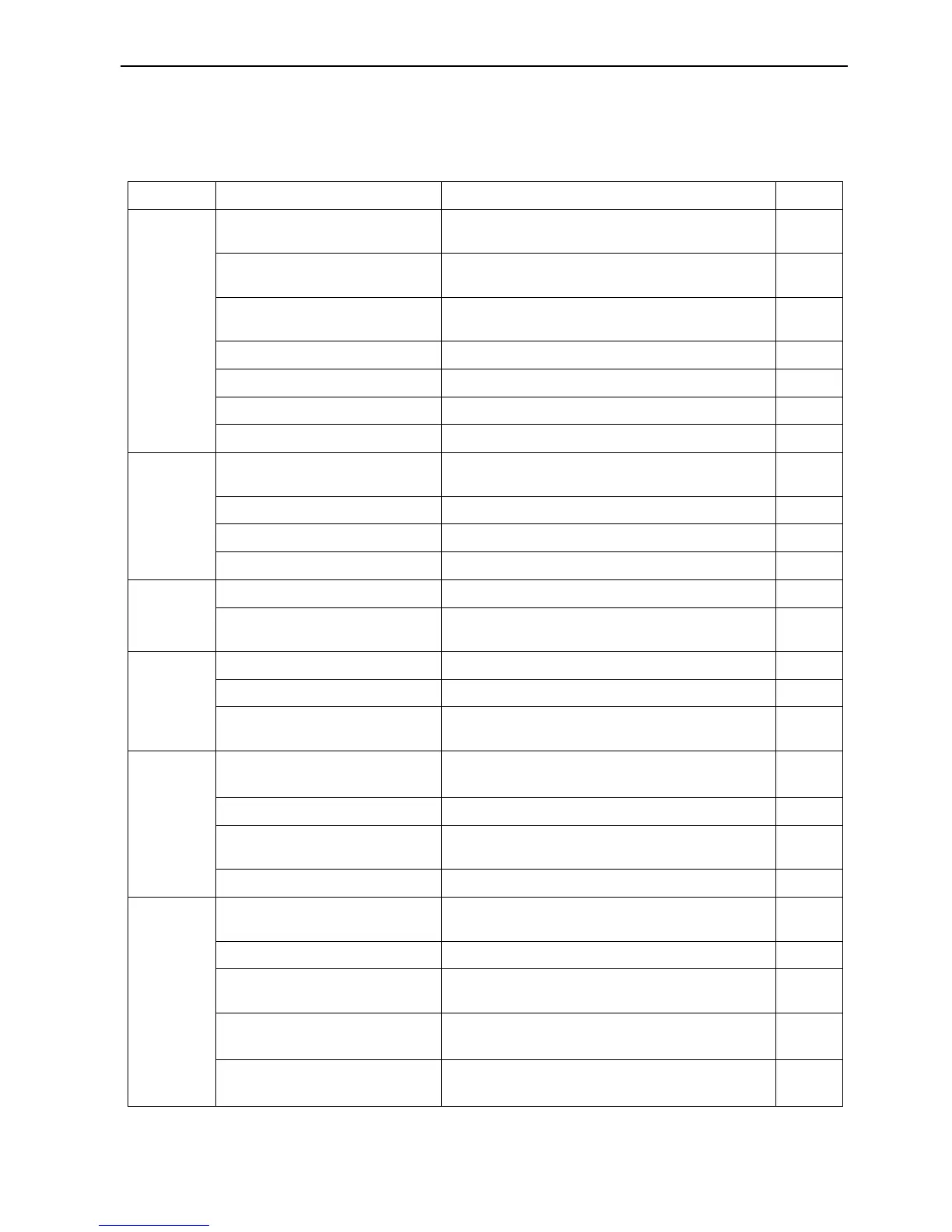

10 TROUBLESHOOTING

10.1 GENERAL

The trouble shooting chart below lists basic problems that may occur during start-up and operation. For more

detailed information regarding the hydraulic and electrical systems contact your area Ransomes Distributor.

Symptoms Possible causes Action Section

Engine will

not start.

1. Glow Plug has not timed out. 1. Reset ignition switch and allow glow plug to

time out before cranking engine.

2. Battery low on charge or

defective

2. Inspect condition of battery and battery connections

3. Fuel tank empty or fuel

contaminated.

3. Fill tank with fresh fuel. Change filter, Bleed air from

lines

5.6

4. Blown Fuse. 4. Replace Fuse.

5. Defective Starter Relay. 5. Test and replace relay if neccesary.

6. Parking brake not applied 6. Apply parking brake

7. Mow engage lever set to cut. 7. Put hydraulic drive lever into neutral.

Engine

hard to start

or runs

poorly.

1. Fuel tank empty or fuel

contaminated.

1. Fill tank with fresh fuel. Change filter, Bleed air from

lines

5.6

2. Air Cleaner blocked or dirty 2. Check air cleaner, replace as neccesary

3. Injectors, fuel pump. 3. Consult engine manual.

4. Other Engine Problem 4. Consult engine trouble shooting guide.

Engine

Stops.

1. Fuel tank empty 1. Fill with fresh fuel and bleed lines

2. Interlocks not set before leaving

operators seat

2. Apply parking brake and put hydraulic drive lever

into neutral

Engine

Overheat-

ing

1. Coolant level low 1. Inspect and add 50/50antifreeze solution if required.

2. Radiator air intake restricted 2. Clean wire mesh guard at radiator.

3. Waterpump/alternator belt or fan

belt loose or broken.

3. Inspect waterpump/alternator belt and fan belt.

Tighten if necessary.

6.1

Battery not

holding

charge.

Battery light

on.

1. Loose or corroded battery

terminals

1. Inspect terminals, clean and tighten as required

2. Low electrolyte level in battery. 2. Refill battery with distelled water 5.7

3. Alternator belt loose or broken. 3. Inspectwaterpump/alternator belt. Tighten if neces-

sary

6.1

4. Alternator defective. 4. See engine manual.

Cylinders

cut

unevenly.

1. Cylinder to bottom blade not

adjusted properly.

1. Inspect cylinder to bottom blade adjustment.

2. Engine speed too low. 2. Check engine speed, run engine at full throttle.

3. Cylinder speed not adjusted

for turf conditions.

3. Adjust cylinder speed for best cut.

4. Cylinder direction lever set in

reverse

4. Set cylinder direction lever to forward rotation.

5. Ground weight incorrectly

adjusted

5. Adjust ground weight control valve till correct ground

weight is achieved

Loading...

Loading...