10 | Gas connection for gas devices

68 / 84 80.06.083_iCombi Pro-iCombi Classic_IM_V01_en-US

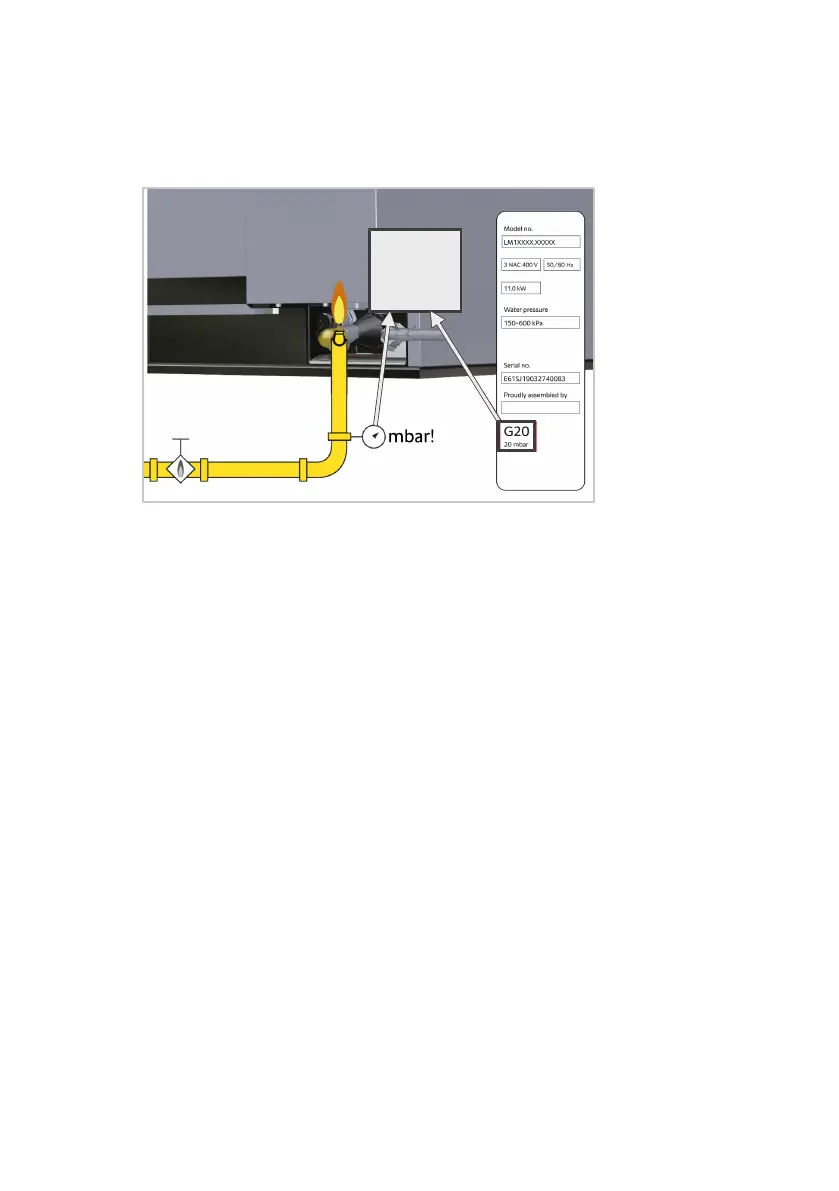

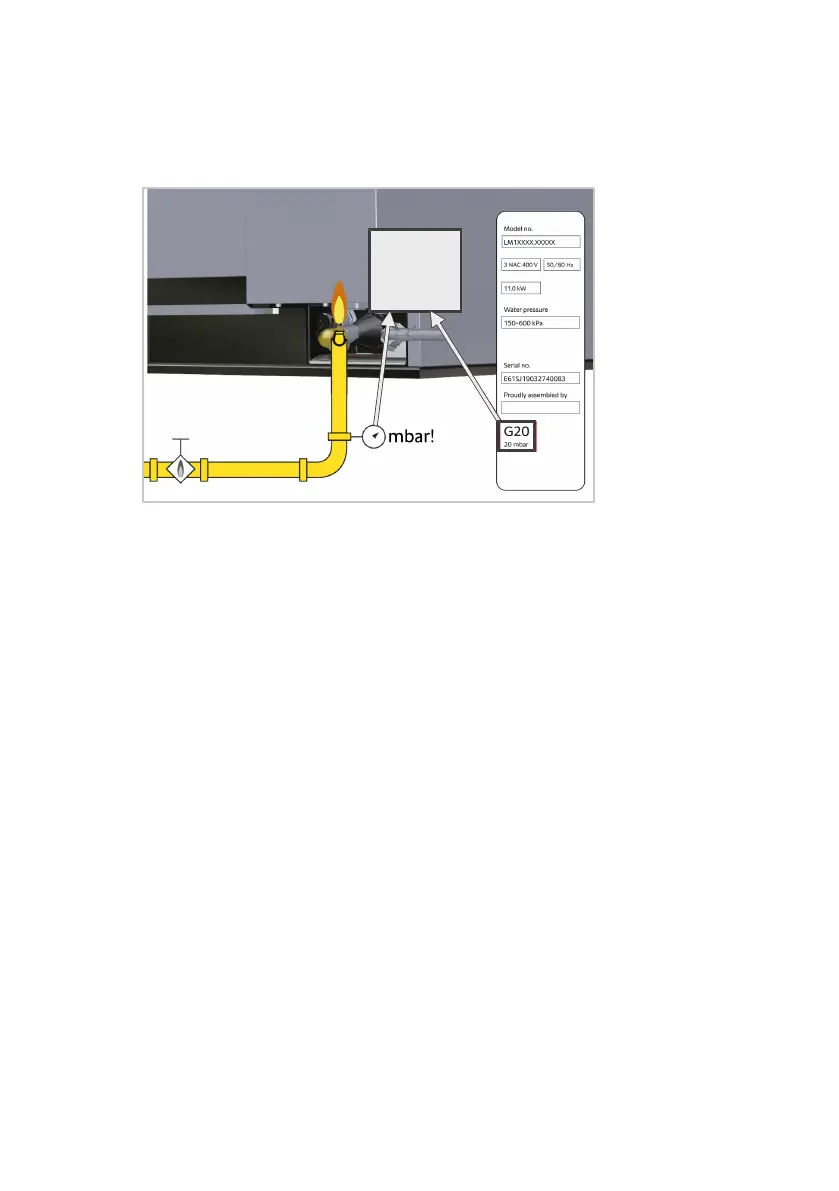

Requirements for gas type and gas pressure

n

Check that the ex-works gas setting on the device matches the actual con-

ditions for the local gas connection.

n

The gas type and the dynamic connection pressure set in the device must

match the specifications on the type plate.

n

If the line pressure deviates from the connection flow pressure of the de-

vice, contact your gas supply company.

n

Observe the regulations of the local gas supply company.

Requirements for gas supply and gas lines

n

The flue gas analysis may only be carried out by a technician authorized by

the manufacturer. The flue gas analysis must be carried out before com-

missioning.

n

The gas connection may only be carried out by a locally approved gas in-

staller.

n

The gas connection line must be designed for the nominal heat load speci-

fied on the type plate.

n

The gas supply and gas distribution in the device must be checked for

leaks using a suitable gas leak detector.

n

The cross-section of the gas line must be designed for the maximum con-

nected power of all consumers, at least ¾ inch.

n

A gas shut-off valve must be installed upstream of each device.

n

All on-site connection parts must be tested in accordance with DIN-

DVGW (the local gas supply companies).

n

The gas line can be connected to a gas socket.

n

A connection with internal thread is required to connect the gas line.

n

The device must be secured against slipping.

n

For values of undiluted CO greater than 174.7 mg/m³ [150 ppm] for hot

air and greater than 465.8 mg/m³ [400 ppm] for steam, the burner setting

must be checked by a company-trained and certified technician in accor-

dance with the setting instructions, and reset if necessary. Subsequently, a

flue gas analysis must be carried out by the technician.

n

Observe the maintenance instructions for gas components.

n

The gas installation must comply with CGA-B 149.1 natural gas regula-

tions or CGA-B 149.2 propane gas regulations.

Loading...

Loading...