85

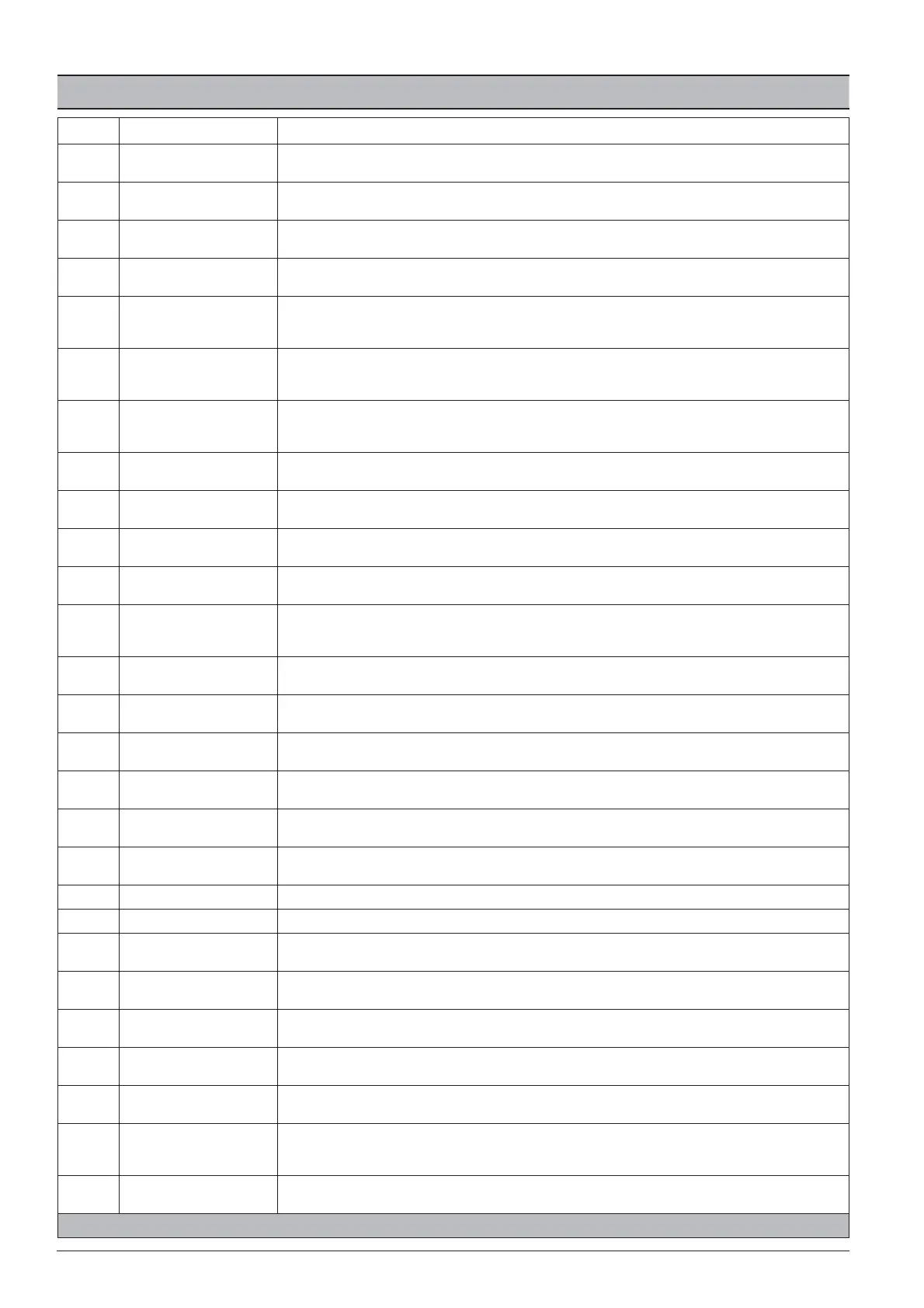

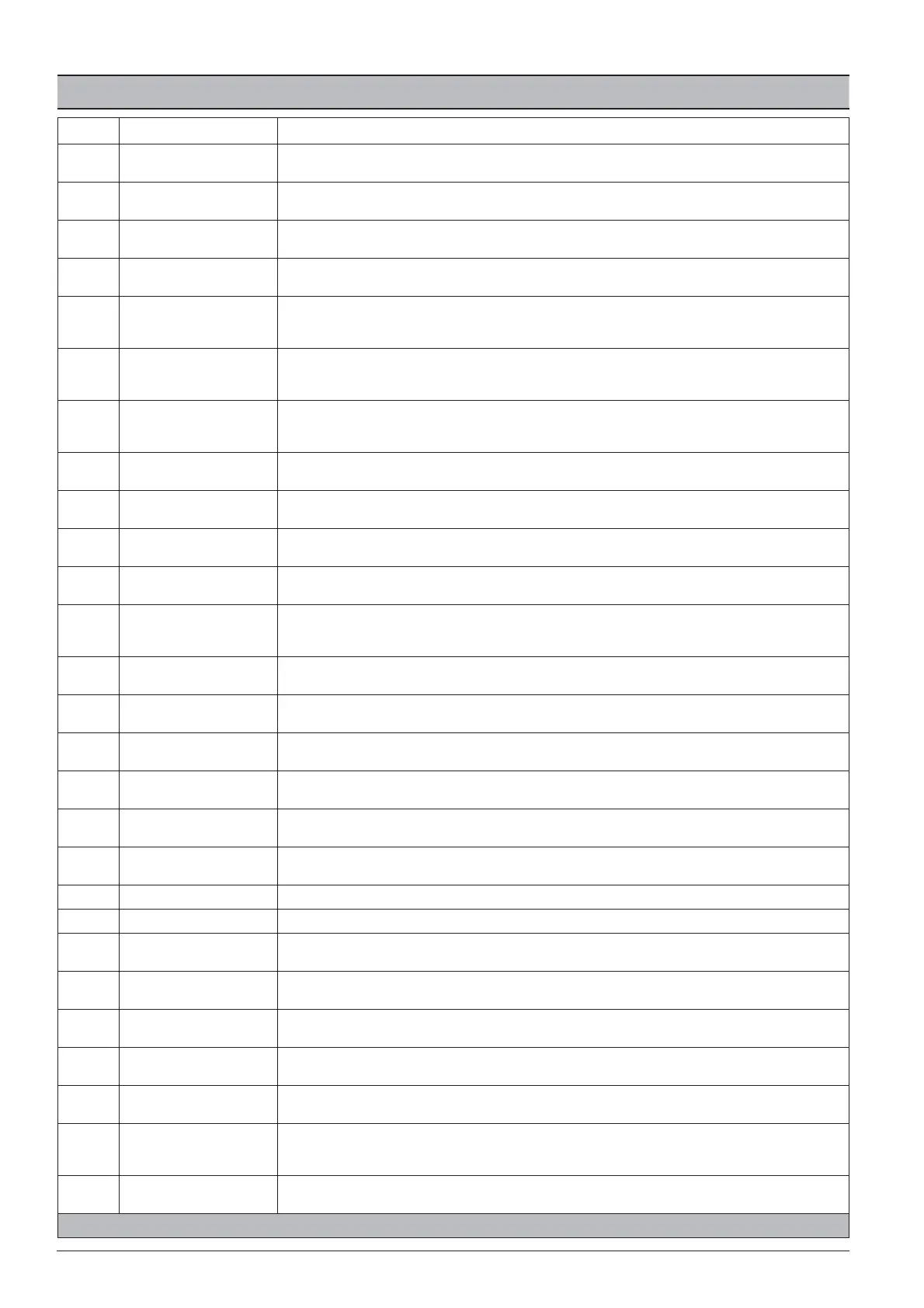

INVERTER TRACTION ALARMS

Alarm Cause Description and Solution

AL TR 8 WATCH DOG

Problem in the WATCHDOG electric circuit, which loses the ability to activate or inhibit system power. If motor phase continu-

ity is veri ed, the problem is related to the system logic (inverter) which must, therefore, be replaced.

AL TR 13 EEPROM KO

Problem with parameter memory. Try running a CLEAR EEPROM to restore it. If the operation is unsuccessful, replace the

damaged EEPROM.

AL TR 17 LOGIC FAILURE #3

Failure of hardware circuit that supervises and protects the system from overcurrent peaks by opening the three-phase brid-

ge. The problem is related to the system logic (inverter), which must, therefore, be replaced.

AL TR 18 LOGIC FAILURE #2

Failure of hardware circuit that guarantees sine wave timing. The problem is related to the system logic (inverter), which must,

therefore, be replaced.

AL TR 19 LOGIC FAILURE #1

Overvoltage or undervoltage signalled. Trips when the battery charge is excessively di erent (approx. + or - 20%) from the no-

minal value. In this case, you must identify and prevent the cause of the problem (generally, overvoltage is when regeneration

is too high, undervoltage is when the battery is too low). It is not related to the system.

AL TR 30 VMN LOW

Diagnosis at start-up that trips when the measured phase voltage is too low compared to the expected value. Make sure

the motor power cables are securely connected (a disconnected or poorly contacted phase causes errors). If the power con-

nections are in order, then the damage is likely related to the system power section and thus, it must be replaced.

AL TR 31 VMN HIGH

Similar to VMN LOW, this diagnosis trips when the measured phase voltage is too high compared to the expected value. Make

sure the motor power cables are securely connected, intact and not shorted. If the power connections are in order, then the

problem can be attributed to the system power section and thus, it must be replaced.

AL TR 37 CONTACTOR CLOSED

The general contactor power contact is closed even if its reel is not piloted. Make sure the contactor has not got stuck or

damaged and in the event, replace it.

AL TR 38 CONTACTOR OPEN

The general contactor power contact is closed even if its reel is being piloted. Make sure the reel wiring is not interrupted,

poorly wired or damaged in general. Replace it if necessary.

AL TR 49 I=0 EVER

When the motor is in movement, the system current sensor sees a zero piloting current. The sensor, therefore, is damaged

and the control must be replaced.

AL TR 53 STDBY I HIGH

Unlike the previous point, the piloting current is always high, even when it should be zero. If the error persists, the control is

damaged and must be replaced.

AL TR 60 CAPACITOR CHARGE

During the pre-charge stage (the one between switching on the key and closing the general contactor), the voltage at the

pre-charge condenser heads does not reach full capacity. Make sure there are no inductive charges parallel to the condensers

and that no problems intervene in the motor or system power section.

AL TR 61 HIGH TEMPERATURE

Warning indicating that the control temperature has exceeded the critical threshold (approximately 72°). The machine is

stopped to allow the control to cool down.

AL TR 65 MOTOR TEMPERATURE

Warning indicating that the motor temperature has exceeded the critical threshold (depends on the motor). The machine is

stopped to allow the motor to cool down.

AL TR 75 CONTACTOR DRIVER

The line contact reel power voltage is lower than expected. Make sure there the general contactor reel is not shorted. If the

error persists, the damage can be attributed to the system piloting circuit, which must, therefore, be replaced.

AL TR 76 COIL SHORTED

This is a diagnosis of the general contactor. If the general contactor reel is excited at start-up despite not being commanded,

then the general contactor opens and signals an error.

AL TR 78 VACC NOT OK

Trips 20" after the accelerator pedal is pressed if no gear is put in (that is, the pedal is pressed uselessly, in neutral gear or

without seat). Make sure the wire is not shorted.

AL TR 79 INCORRECT START

Warning indicating an incorrect machine start-up sequence. Repeat the correct sequence: Sit down properly + Put into Gear

+ Press accelerator pedal.

AL TR 80 FWD+BACK Warning signalling that the forward and backward gear have been requested simultaneously.

AL TR 86 PEDAL WIRE KO Accelerator potentiometer central unit interrupted. Check the accelerator pedal CPOT (potentiometer central unit).

AL TR 236 WRONG BATTERY TYPE

Wrong setting of the parameter SET BATTERY TYPE (menu ADJUSTMENT). It can occur only by setting 24V instead of 36V,

changing the already right default.

AL TR 237 -

Cannot occur while running (it is a warning that signals a manipulation of the SLIP parameters contained in the HARDWARE

SETTING menu).

AL TR 248 CAN BUS KO.

Interruption of communication via CAN. If the diagnosis occurs while assembling, verify that you have not swapped the

wiring of CAN H and CAN L; if the diagnosis occurs while running, check that the wires CAN H and CAN L are not interrupted.

AL TR 250 SENS MOTOR TEMP. KO

Motor temperature probe interrupted. You must make sure the wiring is not interrupted and, if necessary, replace the motor

thermal probe. This warning can appear both during testing and during machine use.

AL TR 251 HANDBRAKE

Warning indicating that the handbrake is engaged. This alarm does not impede operation; simply release the lever before

starting up the run sequence (sit down properly + put into gear + press accelerator pedal).

AL TR 253 ENCODER ERROR

Motor revolution sensor (encoder) interrupted. You must make sure the wiring is not interrupted and, if necessary, replace the

motor sensor. This warning can appear both in testing and during machine use. The system is unable to retroactively check

whether the set-point is consistent with machine behaviour and, therefore, inhibits vehicle operation.

AL TR 254 AUX OUTPUT KO

Failure of the drive piloting the auxiliary output, that is, the magnetic parking brake. Make sure there are no reel wiring pro-

blems that cause a false positive. If the brake is in order, replace the inverter.

NB: For information on the alarms, contact the Assistance Service.

Loading...

Loading...