1 – CALIBRATION SUMMARY

4

1 Calibration Summary

The LM 800i/8000i system operates in a Non-Approved weighing mode. Dynamic or Static weighing is

possible. The system is designed to be easily upgradable for Weights and Measures approved operation,

either for automatic weighing (AWI) or non-automatic weighing (NAWI).

There are a large number of functions within the calibration menu in order to optimise the performance of the

weighing system for a particular loading shovel and the method in which it is to be used. Many settings need

only be made on the initial installation.

The calibration procedure is summarised below. For full information on any of the settings in the calibration

menu (ref. Section 4).

Step 1 Work the machine until

it is up to the normal operating temperature.

Step 2 Go to the "Sensor Setup" menu (ref. section 2.1)

(i) Set "Ram Ratio" The default value of 1.3000 is OK initially, for almost all makes and models of machine.

Known figures are given below.

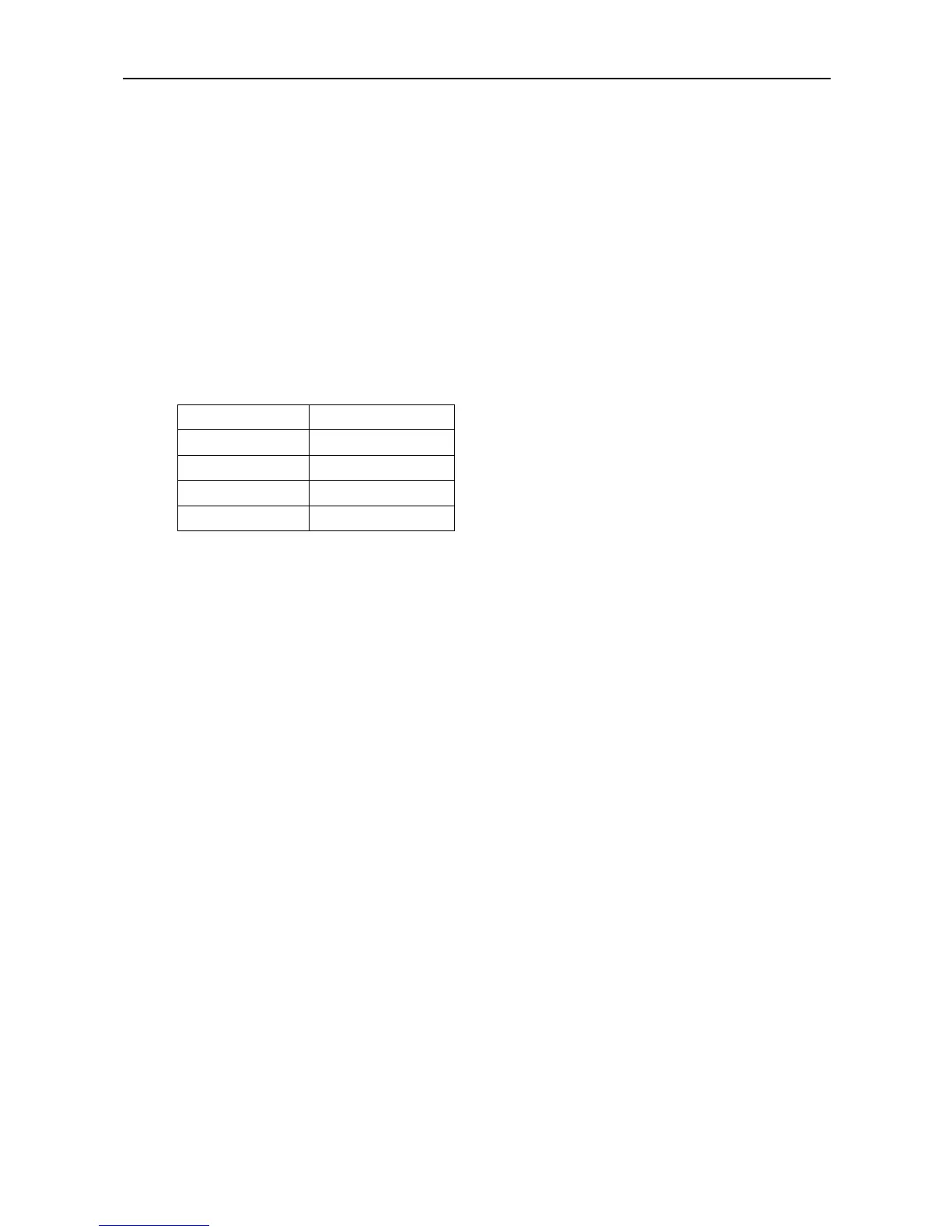

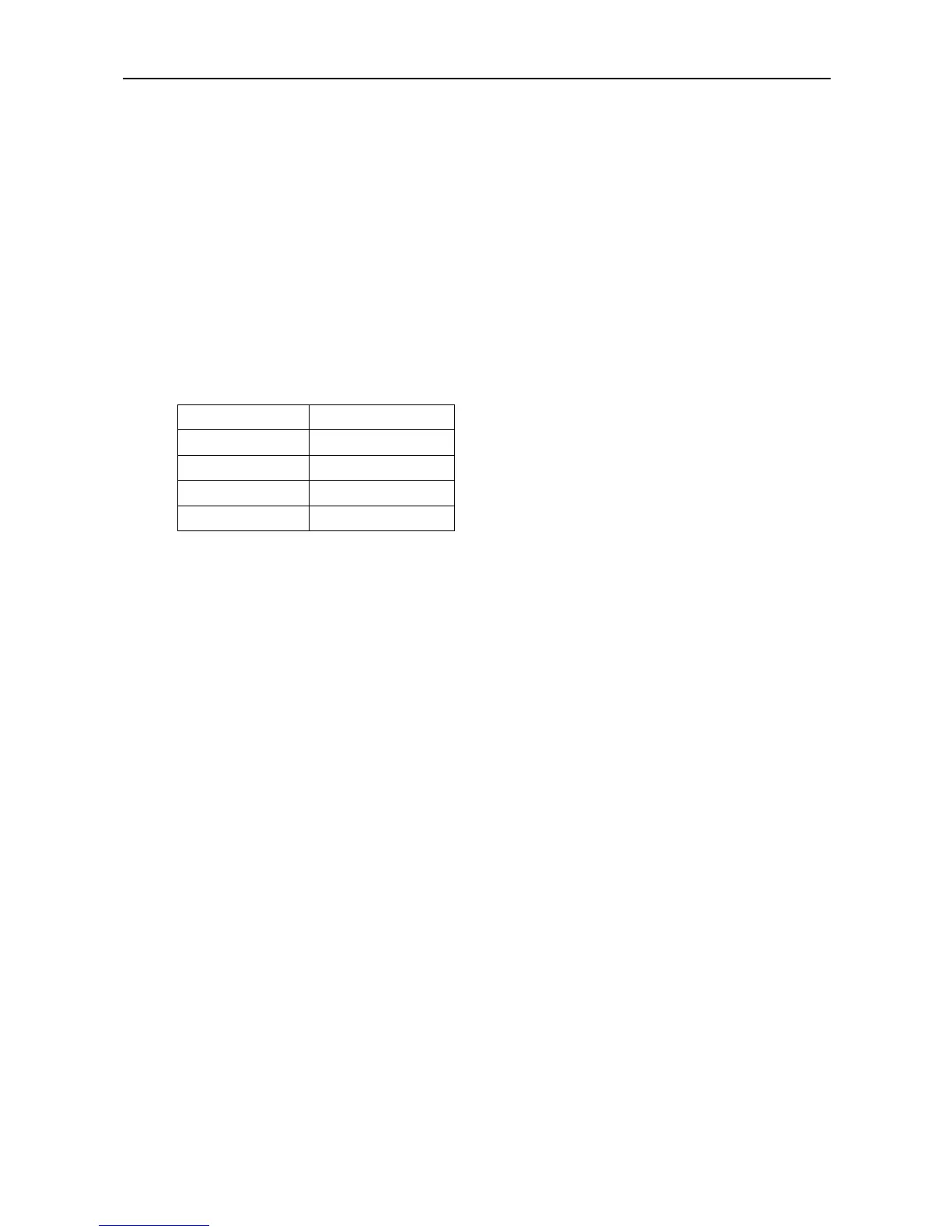

Machine Ram Ratio

VOLVO L120, L150 1.34

ALL KOMATSU 1.30

ALL CASE 1.30

ALL CAT MODELS 1.25

For other machines, you can determine the correct ram ratio by the following method: - Do a slow lift and then

a fast lift. If the weight readings are the same, the Ram Ratio is correct. If the fast lift reading is greater then

reduce the ram ratio, and vice versa.

(ii) Set "Dual Sensor" to "DIFF".

(iii) The default settings for "Live Static" (AUTO), and "Mode" (DYN/STAT) enable both dynamic and static weighing

modes, and a live readout for the "last bucket" weighing mode. If you require static weighing mode only or

dynamic weighing mode only, you must change these settings accordingly.

NOTE: Some CASE and Liebherr machines should be operated only in Static weighing mode.

Step 3 Go to the "AutoCal" menu (ref. section 2.2)

Follow the screen prompts for the calibration routine ("Dyn. Diff Setup", “Static Empty Lift”, "Dyn. Speed

Comp.", “Static Full Lift”, "Static Comp.", "Zero" and then "Cal Weight"), to establish accurate weighing. To

perform the weight calibration ("Cal Weight"), load the bucket (preferably to its full capacity) with a known

weight of material.

NOTE: If you don't know the exact weight, you can make an estimate and then use the "NUDGE" facility afterwards to

correct the calibration factors.

The calibration figures resulting from the AUTOCAL procedure will apply to loading attachments 'A' to 'H'. To

ensure accurate results when using a different attachment, adjust the calibration using the NUDGE facility.

Step 4 Check the weight reading (ref. section 2.4)

Zero the system and load a truck. Note the weighbridge (weigh scale) reading against the instrument reading.

If they are different, use the NUDGE facility to enter the two readings. The calibration factors are adjusted

automatically.

Step 5 Operator Instruction.

Please discuss the loading sequence and loading routine with the operator(s) of the loading shovel. Ride with

the operator and explain the weighing methods, auto kick-out, auto / manual entry, and the importance of

smooth operation while weighing.

Loading...

Loading...